Crossing hole, heat injection and hydraulic flushing synergistic extraction-promoting enhancing method

A layer-penetrating drilling and hydraulic punching technology, which is applied in earth square drilling, liquid/gas jet drilling, wellbore/well components, etc., can solve the problem of high temperature conditions that cannot be applied to conventional hole sealers and the heating efficiency of heat injection medium Low gas consumption, poor drainage effect and other problems, to achieve good economy, ensure the effect, and improve the effect of gas drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

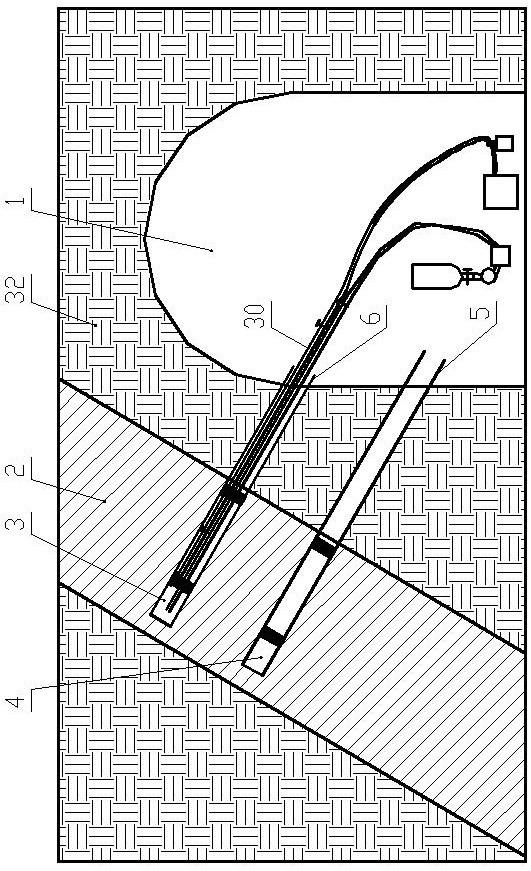

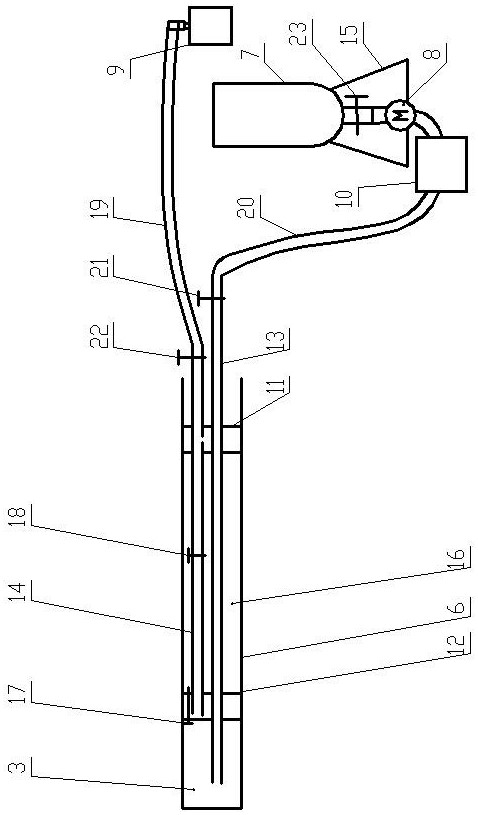

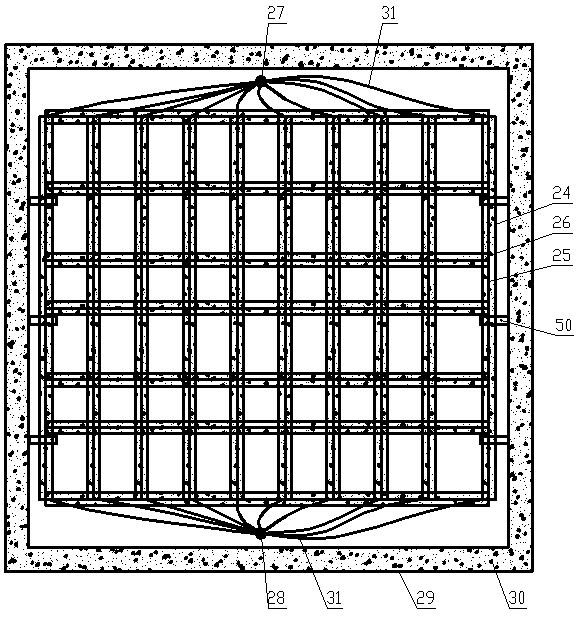

[0043] Such as Figure 1-Figure 5 As shown, the method for enhancing pumping through bed drilling and heat injection in conjunction with hydraulic punching of the present invention includes the following steps:

[0044] (1) Manipulate the mechanical drilling rig in the floor rock roadway 1 to drill through layers to the coal body 2 (the mechanical drilling rig first drills the rock layer 32, and then drills into the coal body 2), and the end points of each drilling hole are grid-like Arranged in an array, the distance between the end points of two adjacent boreholes is 6-9m, and any two adjacent boreholes are named heat injection hole 3 and extraction hole 4 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com