Freezing type pipe shed and construction method thereof

A construction method and technology of freezing pipes, which are applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of low strength of frozen soil, loss or water gushing and sand gushing, poor adaptability of freezing method, etc., and achieve good safety results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

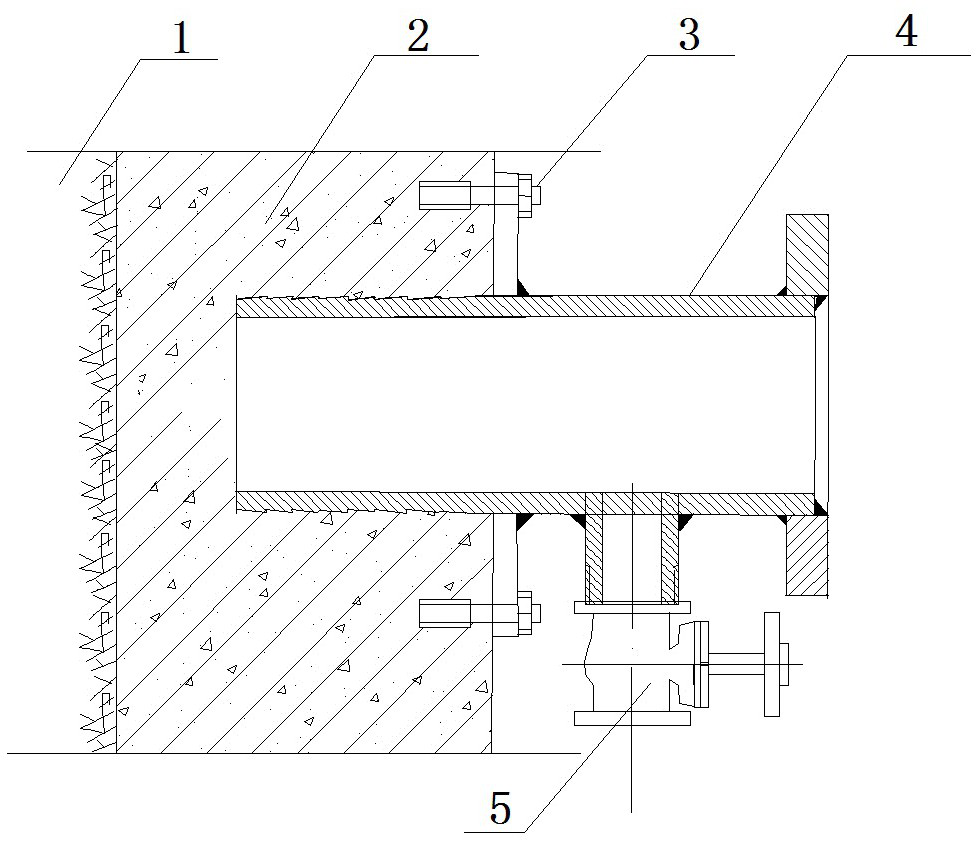

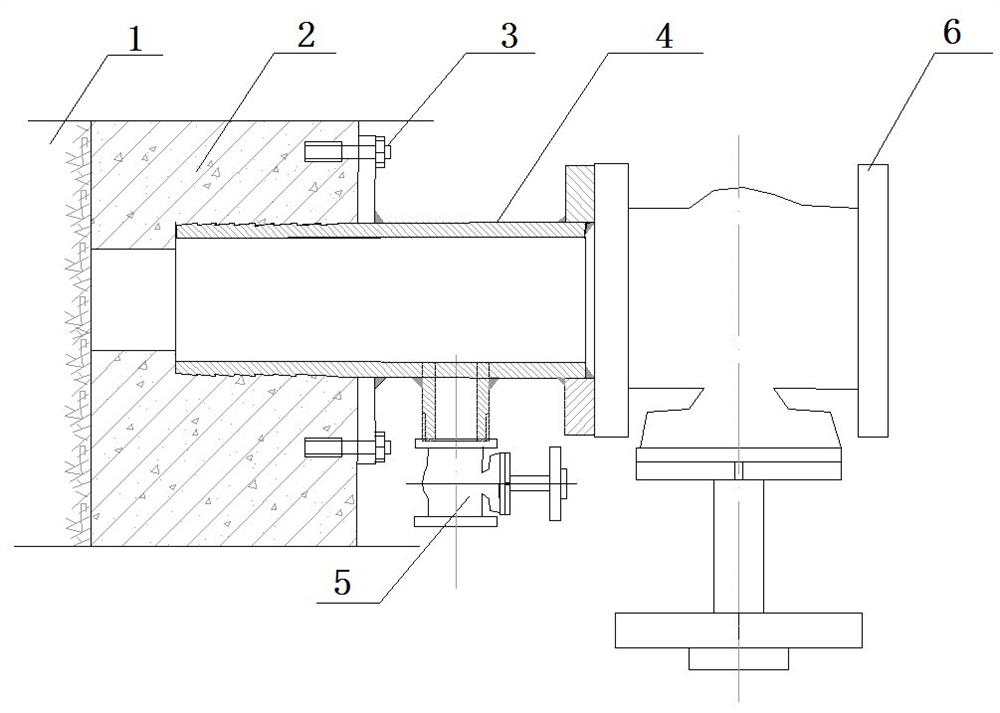

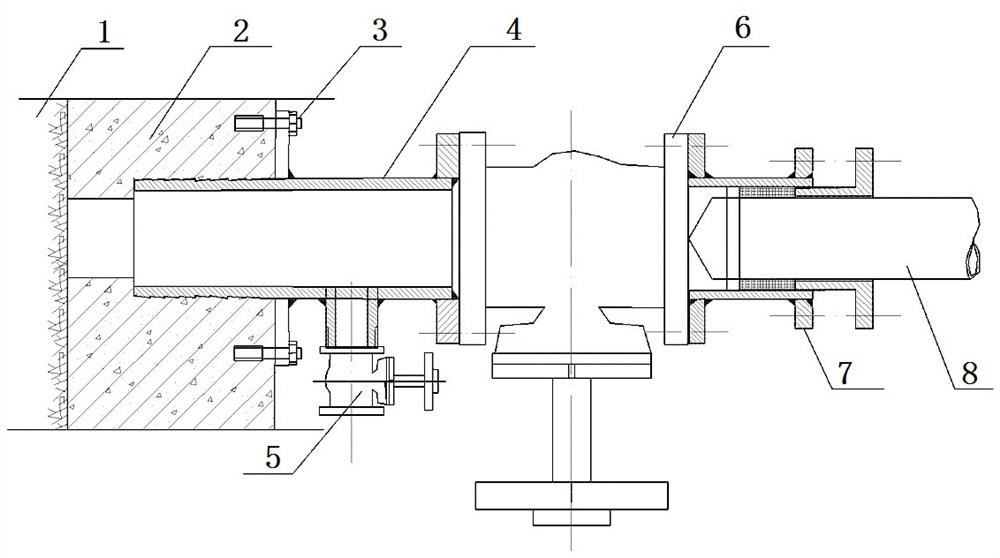

[0027] Example: such as Figure 1-6 As shown, the present embodiment specifically relates to a frozen pipe shed and its construction method. The specific structure of the frozen pipe shed is as follows Figure 5 As shown, it includes an orifice pipe 4 fixedly installed on the underground diaphragm wall 2, a pipe shed 9 passing through the orifice pipe 4, a freezing pipe 10 arranged in the pipe shed 9, and a filling between the freezing pipe 10 and the pipe shed 9. The cement mortar layer 15 in the annular gap between them.

[0028] like Figure 5 As shown, the front end of the orifice pipe 4 is embedded in the hole of the underground diaphragm wall 2 to a certain depth and the tail end is exposed outside the underground diaphragm wall 2. On the wall surface of the exposed part of the orifice pipe 4, a welding flange is passed and passed through The setting of the expansion bolt 16 is thus fixed on the underground continuous wall 2, and a bypass valve 5 is arranged on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com