Parallel grid simulation method for aero-engine combustion chamber through-flow model

A technology of aero-engine and simulation methods, applied in design optimization/simulation, computer-aided design, CAD numerical modeling, etc., can solve problems such as incomplete flow drawing depiction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0181] Example description:

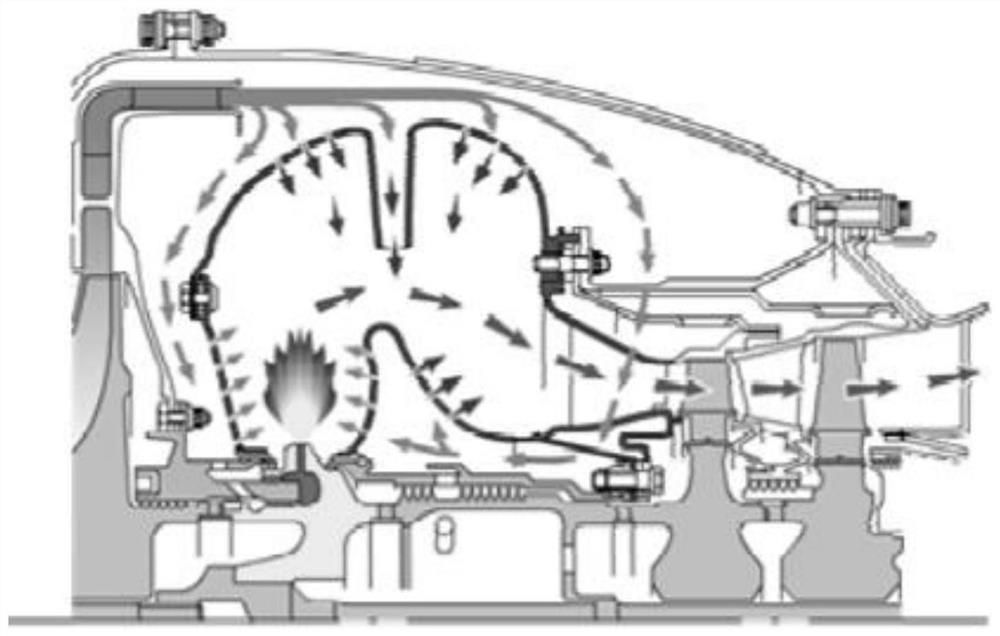

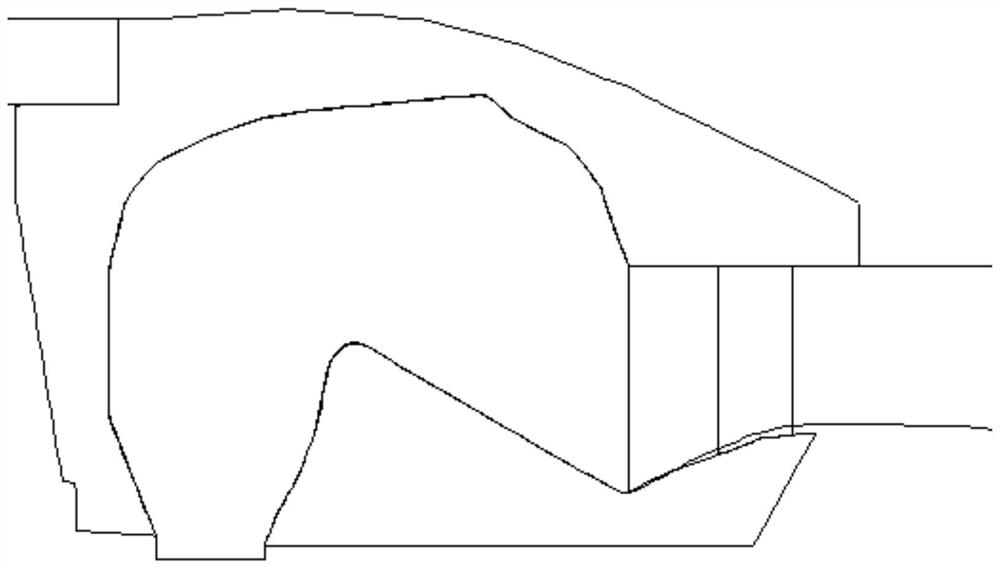

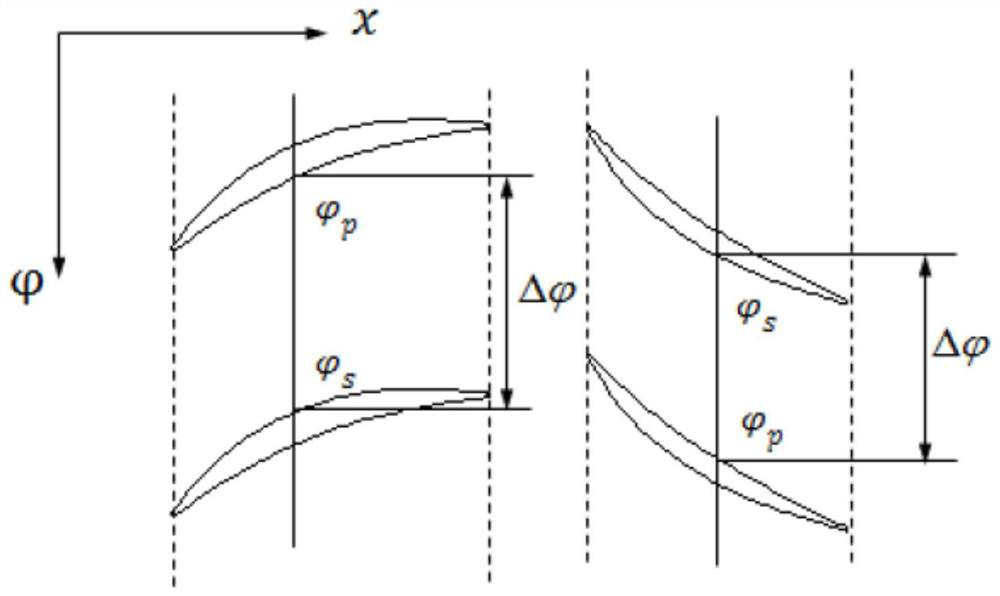

[0182] Based on the throughflow analysis software developed by our research group, combined with the parallel grid method of the combustion chamber intake bucket in the aeroengine throughflow model proposed by the present invention, the simulation fidelity of the combustion chamber intake bucket in the throughflow simulation software is preliminarily explored Effects on the flow field for throughflow calculations. Finally, the effectiveness of the present invention is verified by comparative analysis with the results of three-dimensional numerical simulation, experimental data, and flow calculation results obtained by Ivanov et al. by simplifying the intake funnel into large holes.

[0183] The first step, flow field numerical simulation

[0184] The verification object adopted in this example is the baffle annular combustor adopted by a small turbojet engine, and its section view and meridian view are respectively as follows Figure 10 and Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com