Automatic equipment for automatically removing cotton yarns from core wires of wires

An automatic equipment, cotton yarn technology, applied in circuit/collector parts, electrical components, circuits, etc., can solve the problems of uncontrollable consistency of production results, reduced production accuracy, mechanical wear, etc., to meet production accuracy and production costs. Low, fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

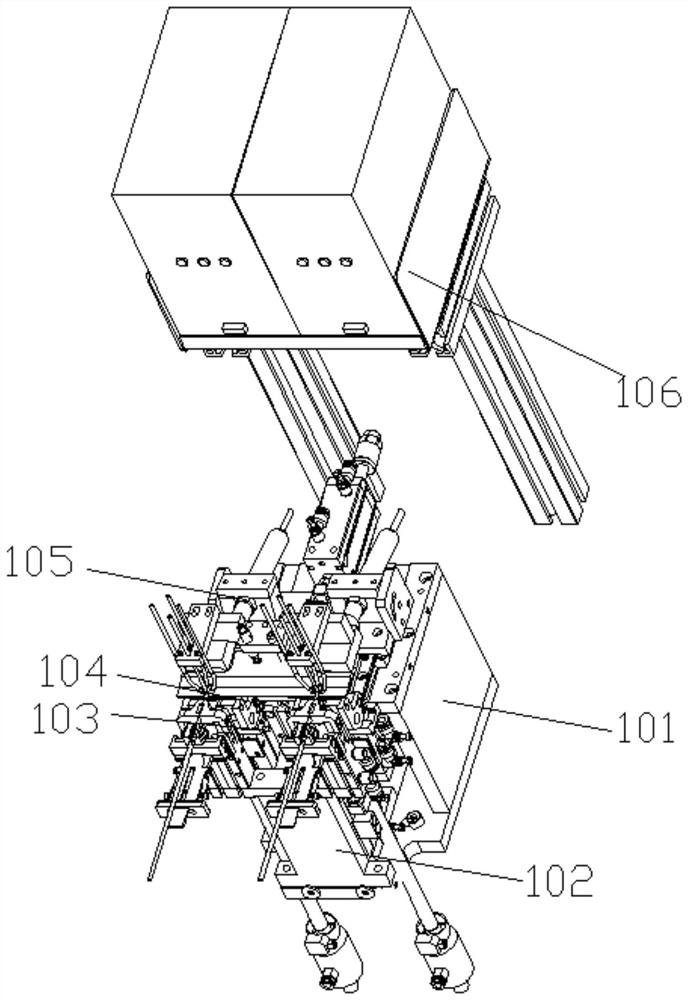

[0028] refer to Figure 1-7 , an automatic device for automatically removing lint yarn from the core wire of a wire, including an installation support assembly 101, a positioning assembly 102, a thread support blowing cotton yarn assembly 103, a straightening cotton thread assembly 104, a soldering iron soldering pen clamping assembly 105, a control assembly 106, and a positioning assembly 102 is fixedly installed on the support assembly 101, the thread-supporting blown cotton yarn assembly 103 is fixedly installed on the installation support assembly 101, the straightening cotton thread assembly 104 is fixedly installed on the support assembly 101, and the soldering iron soldering pen clamping assembly 105 is slidably installed on the installation support assembly Top of 101.

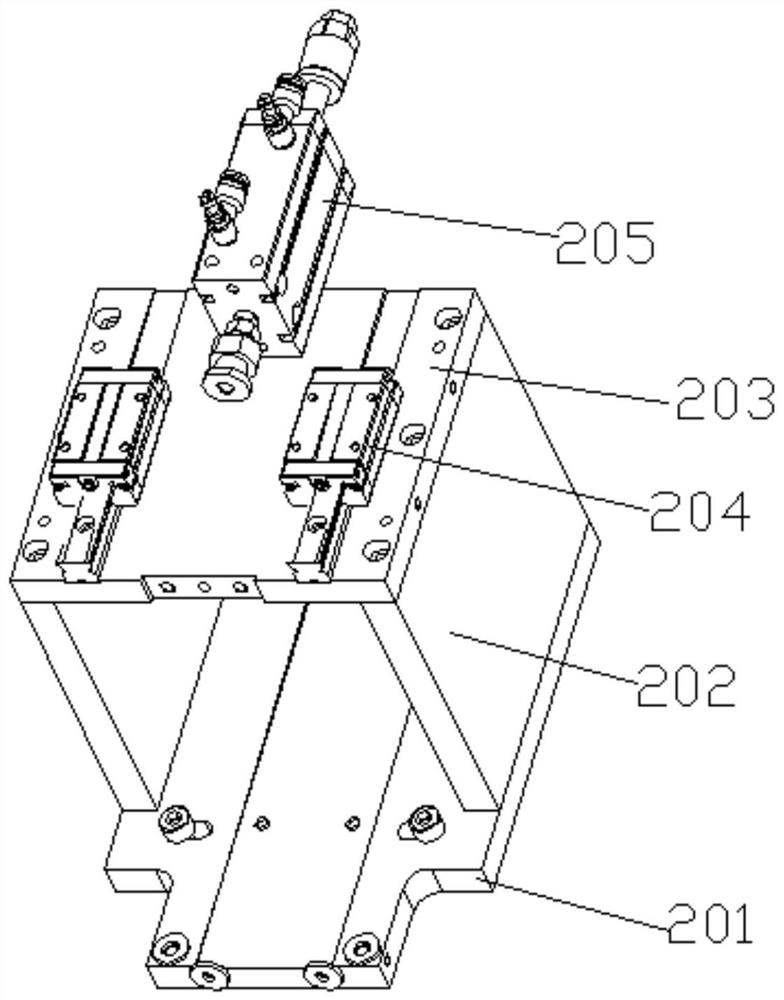

[0029] In this embodiment, the installation support assembly 101 includes a first installation base plate 201, two support plates 202, a functional component support plate 203, two soldering iron and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com