Motor, motor assembly, food processor, air supply device and household appliance

A technology of components and magnetic parts, which is applied in the field of electric vehicles and a power generation device, can solve the problems of time-consuming and laborious maintenance of electric motors, and achieve the effects of easy daily maintenance, low height, easy disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

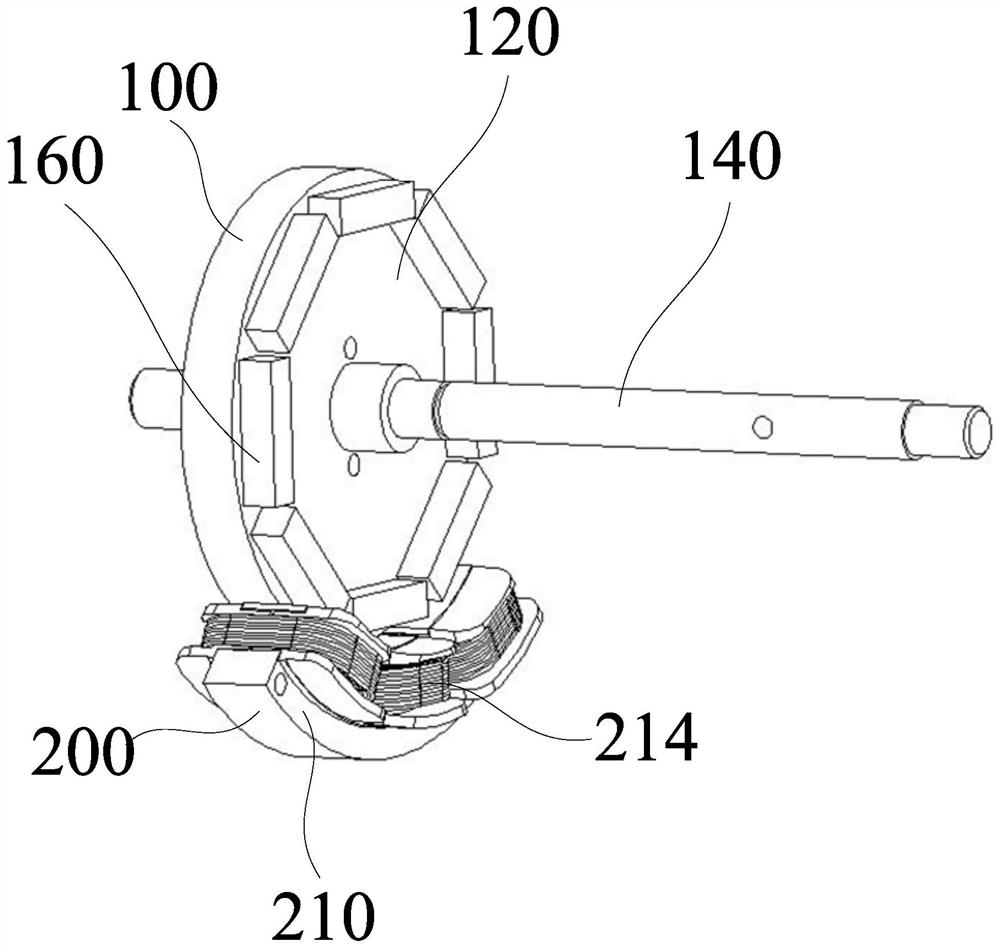

[0073] Such as Figure 1 to Figure 9 As shown, the motor according to the embodiment of the first aspect of the present invention includes a rotor assembly 100 and a stator assembly 200 .

[0074] Wherein, the stator assembly 200 has a mating surface matched with the rotor assembly 100, and the mating surface is arranged opposite to a part of the outer peripheral surface of the rotor assembly 100, so that the rotor assembly 100 can be aligned with the stator assembly 200 along its radial direction and / or axial direction. separate.

[0075] In this embodiment, an electric machine is provided that includes a rotor assembly 100 and a stator assembly 200 . Wherein, the stator assembly 200 is located outside the rotor assembly 100, and the surface of the stator assembly 200 that matches the rotor assembly 100 is a mating surface, and the mating surface is arranged opposite to a part of the outer peripheral surface of the rotor assembly 100, that is, the stator assembly 200 does no...

Embodiment 2

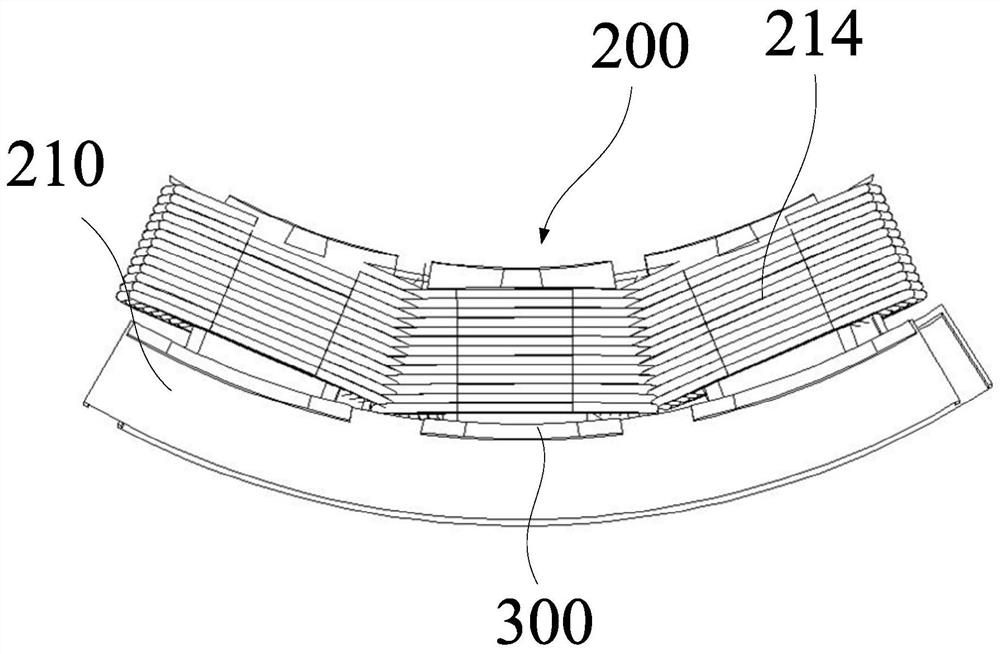

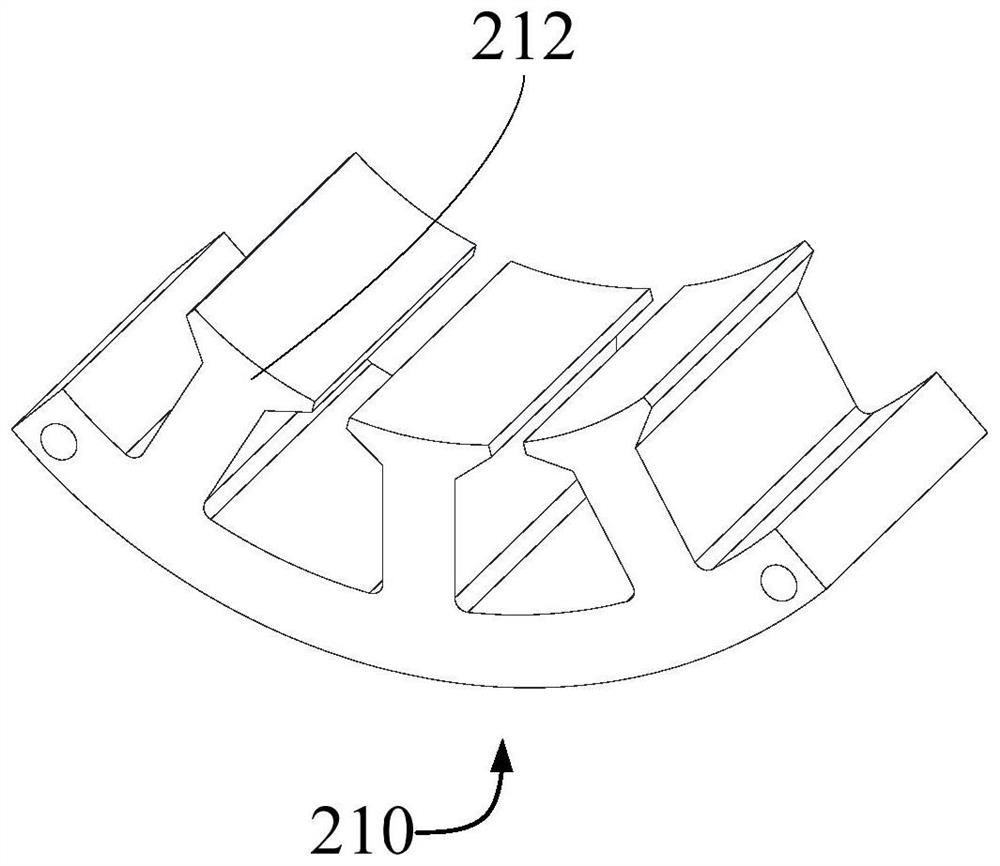

[0088] Such as Figure 1 to Figure 5 As shown, in one embodiment of the present invention, optionally, the number of the stator assembly 200 is one, and the stator assembly 200 includes: a stator core 210 with stator teeth 212 thereon; at least two stator windings 214, at least two The stator windings 214 are respectively arranged on the stator teeth.

[0089] In this embodiment, based on the fact that the number of the stator assembly 200 is one, the stator assembly 200 includes a stator core 210 and at least two stator windings 214, the stator core 210 has stator teeth 212, and the at least two stator windings 214 are respectively Arranged on the stator teeth 212 , at least two stator windings 214 can generate a magnetic field when energized, so that the rotor assembly 100 rotates under the action of the magnetic field.

[0090] In any of the above embodiments, optionally, there are multiple stator assemblies 200 , and the plurality of stator assemblies 200 are combined or ...

Embodiment 3

[0105] Such as Figure 1 to Figure 5 As shown, in any of the above embodiments, optionally, the number of stator teeth 212 is greater than or equal to three, and the polarities of the stator windings 214 on any two adjacent stator teeth 212 are different.

[0106]In this embodiment, when the number of stator teeth 212 is greater than or equal to three, it is preferable to energize the two adjacent stator windings 214 together, and make the polarities of the two adjacent windings reverse, so that the rotor assembly 100 is subjected to a force in a tangential direction, so as to provide power for the rotation of the rotor assembly 100 .

[0107] Specifically, when the number of stator teeth 212 is set to three, the first stator winding 214 and the second stator winding 214 are energized, and the first stator winding 214 generates an N-pole magnetic field to S of the magnetic member 160 in the rotor assembly 100. Pole attraction, the second stator winding 214 generates an S pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com