Oxygen surface humidifying device

A humidification and oxygen technology, applied in the field of medical devices, can solve the problems of high production cost, inconvenient and complicated processing and production, and achieve the effects of low production cost, various forms and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

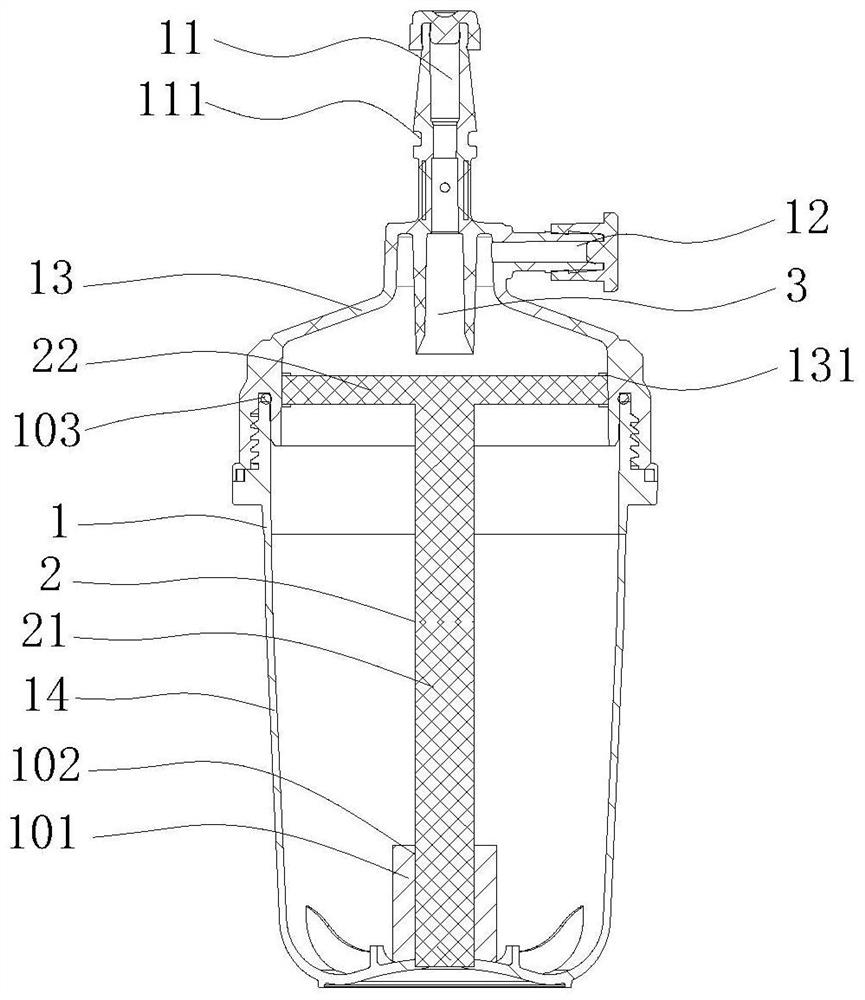

[0042] figure 1 It is a structural diagram of Embodiment 1 of the oxygen surface humidification device of the present invention. see figure 1, the oxygen surface humidification device of the present invention includes a main casing 1 and a humidification unit 2 , and the humidification unit 2 is installed in the main casing 1 . The main housing 1 is made of medical-grade plastic material and is in the shape of a bottle as a whole. The main housing 1 includes a bottle cap 13 and a bottle body 14. The bottle cap 13 and the bottle body 14 are connected by threads. In order to ensure that the bottle cap 13 and the bottle The tightness between the body 14 is installed on the sealing ring 103 at the junction of the bottle cap 13 and the bottle body 14 . The main housing 1 is provided with at least one inlet pipe 11 for dry oxygen to enter the main housing 1 and at least one outlet pipe 12 for humidified oxygen to flow out. The main housing 1 is filled with humidification liquid. ...

Embodiment 2

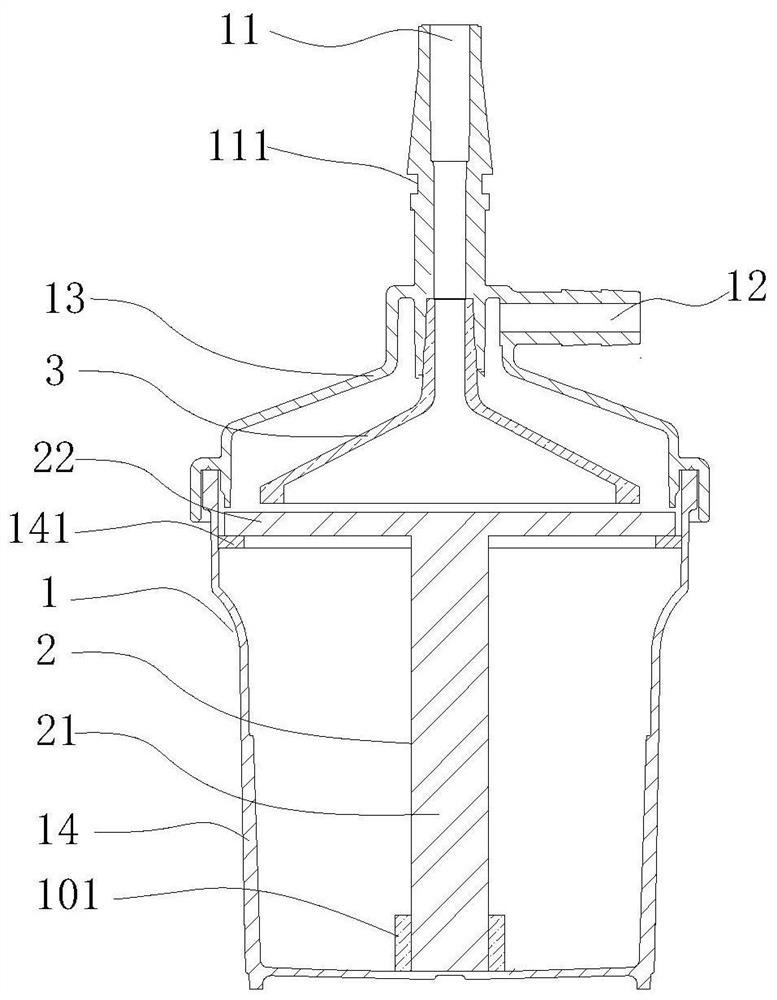

[0047] figure 2 It is a structural diagram of Embodiment 2 of the oxygen surface humidification device of the present invention. see figure 2 , in the present embodiment, the oxygen guide body 3 is a trumpet-shaped structure, and its small end is connected to a position opposite to the coaxial center of the air intake pipe 11 inside the bottle cap 11, and its horn end opening is close to the humidification umbrella 22. The upper surface, and keep a certain gap with the upper surface of the humidification umbrella 22, so that oxygen can pass through smoothly. The oxygen guide body 3 is arranged in a trumpet-shaped structure, which can guide the flow of dry oxygen to the surface of the humidification umbrella, increase the contact area between oxygen and the humidification umbrella 22, and further enhance the humidification effect.

[0048] In addition, in this embodiment, the humidifying umbrella 22 is installed on the bottle body 14 , and at the same time, an annular step ...

Embodiment 3

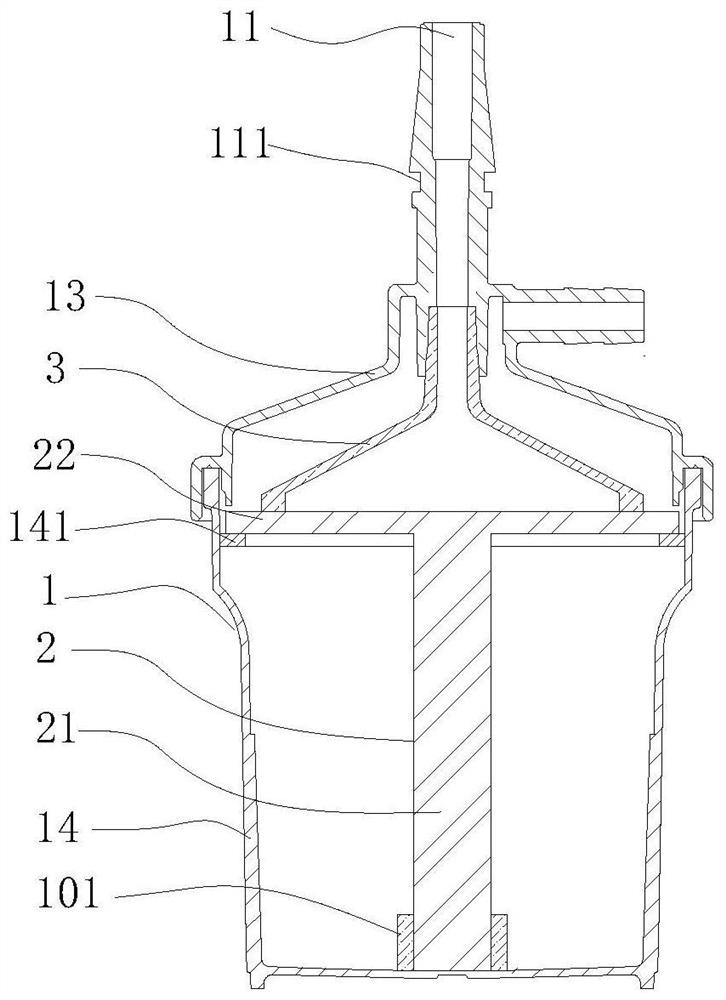

[0050] image 3 It is a structural diagram of Embodiment 3 of the oxygen surface humidification device of the present invention. Figure 4 for image 3 The bottom view of the guide body 3 in the shown oxygen surface humidification device; Figure 5 for image 3 Top view of the humidification unit 2 in the shown oxygen surface humidification device. see Figure 3 to Figure 5 The difference between the present embodiment and the second embodiment is that the opening of the oxygen guiding body 3 abuts against the upper surface of the humidification umbrella 22 . A plurality of first guide grooves 131 extending in the radial direction of the humidification umbrella 22 are provided on the lower surface of the open end of the oxygen guide body 3 in contact with the humidification umbrella 22; or, in the The upper surface of the humidification umbrella 22 in contact with the oxygen guide body 3 is provided with a plurality of first guide grooves 131 extending radially along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com