Latex paint blending device

A latex paint and blending tank technology, applied in transportation and packaging, mixer accessories, dissolution, etc., can solve problems affecting the blending quality and efficiency of latex paint, large raw material particles, etc., to shorten the blending time and improve efficiency and quality , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

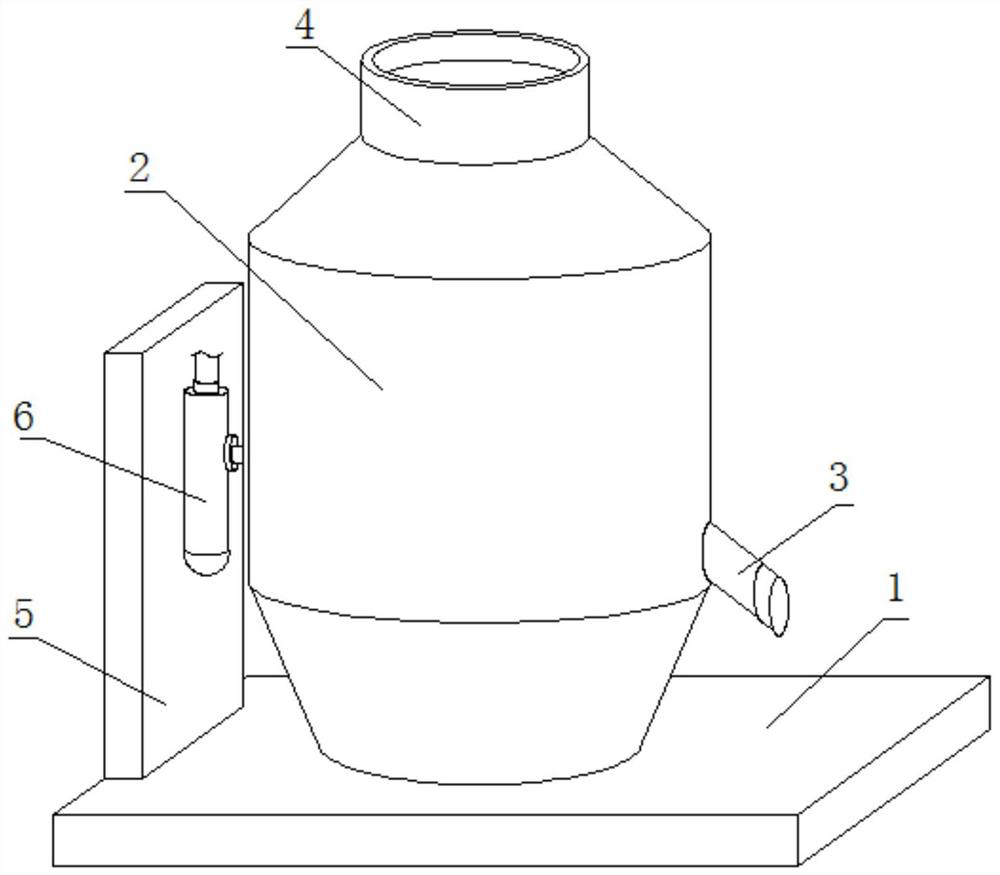

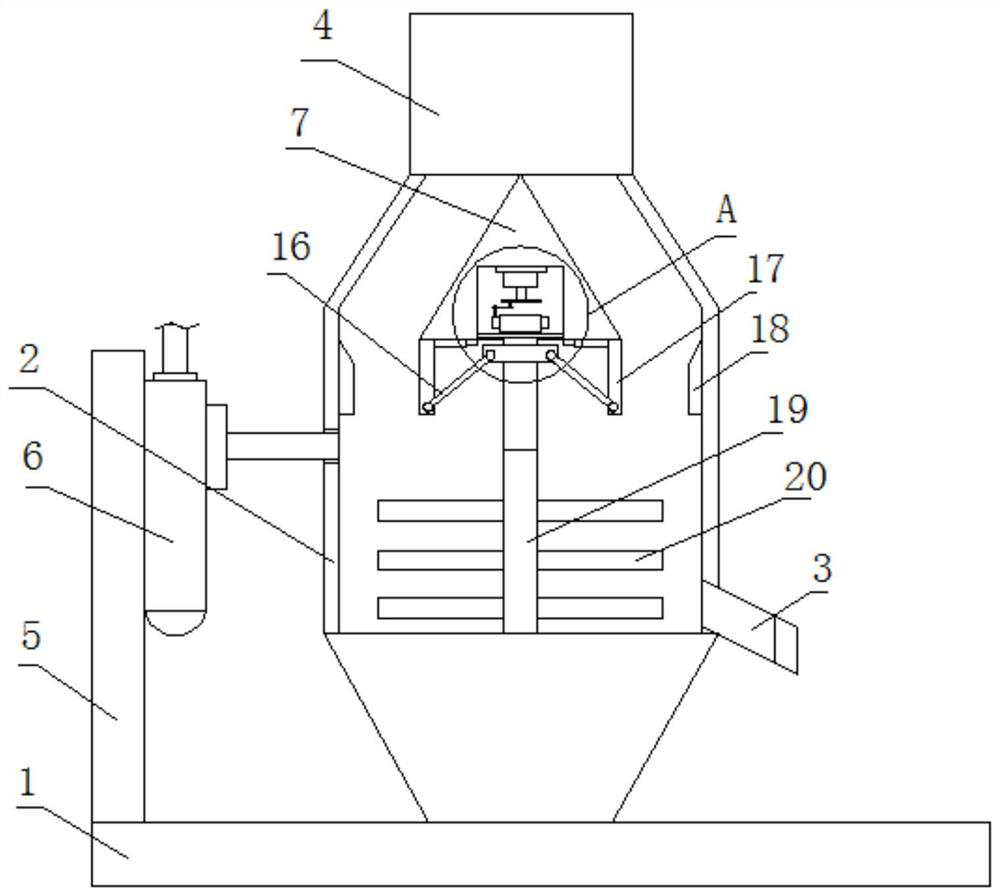

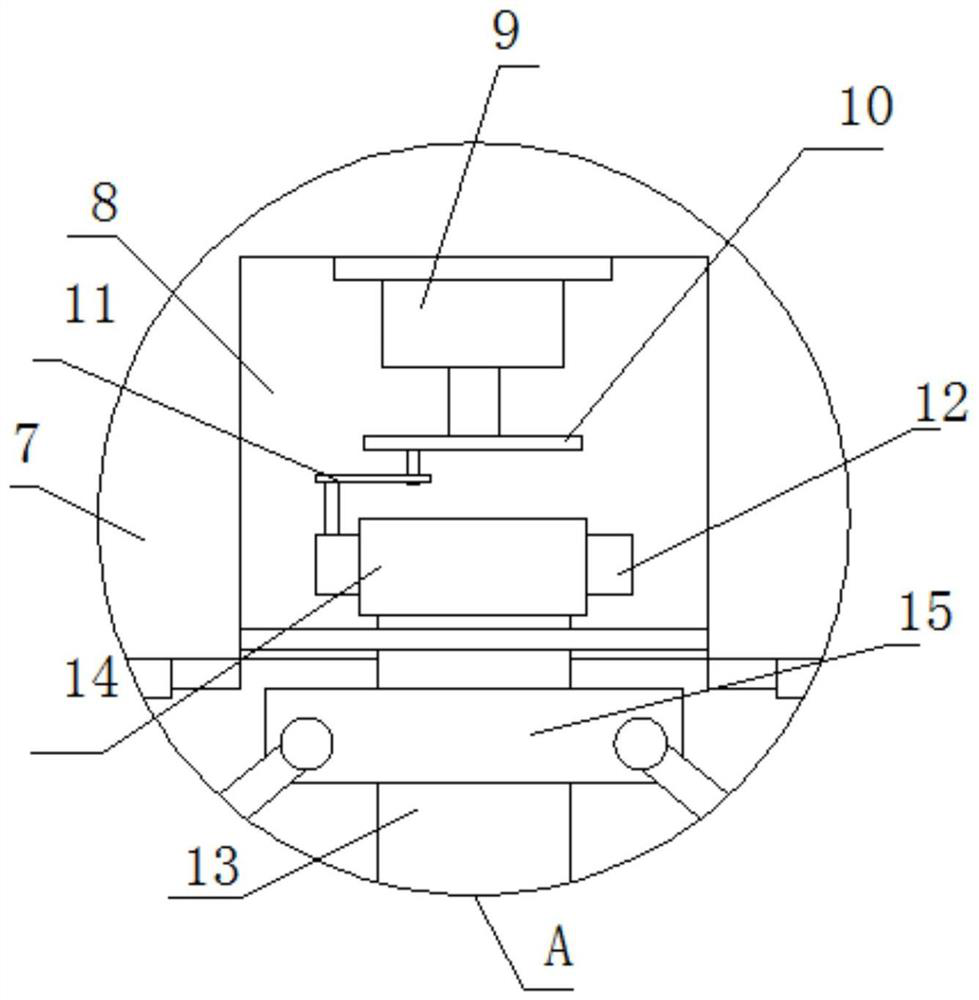

[0020]Refer toFigure 1-3, A latex paint mixing device, comprising a bottom plate 1, a mixing tank 2 is fixedly installed on the top of the bottom plate 1, a triangular plate 7 is fixedly installed on the inner wall of one side of the mixing tank 2, and a mounting groove 8 is opened at the bottom of the triangular plate 7. The groove 8 is provided with a driving mechanism. The driving mechanism is connected with a vertical shaft 13 for transmission, and the bottom of the vertical shaft 13 extends below the triangular plate 7. The vertical shaft 13 is threadedly connected with a threaded block 15 and one side of the threaded block 15 Two connecting rods 16 arranged symmetrically are rotatably installed. The bottoms of the two connecting rods 16 are both rotatably installed with pressure plates 17. The tops of the two pressure plates 17 are slidingly connected with the bottom of the triangular plate 7, and the inner walls of the mixing tank 2 are on both sides. A vertical plate 18 is f...

Embodiment 2

[0024]In the present invention, the drive mechanism includes a drive motor 9 fixedly mounted on the inner wall of the top of the mounting slot 8. The bottom of the output shaft of the drive motor 9 is fixedly mounted with a turntable 10, the bottom of the turntable 10 is rotatably mounted with an action rod 11, and the mounting slot 8 A rack 12 is slidably installed on the inner wall of one side. The top of the vertical shaft 13 extends to the inside of the mounting groove 8 and a gear 14 is fixedly sleeved. The gear 14 and the rack 12 mesh with each other, in order to realize the clockwise and the vertical shaft 13 Reciprocating counterclockwise rotation works.

[0025]In the present invention, the water inlet mechanism includes a mounting plate 5 fixedly mounted on the top of the bottom plate 1, a water inlet pump 6 is fixedly mounted on one side of the mounting plate 5, and the water outlet of the water inlet pump 6 is sealed and threaded with a water outlet pipe, a water outlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com