Diamond antibacterial coating technology

An antibacterial coating and diamond technology, applied in coatings, antifouling/underwater coatings, devices for coating liquid on the surface, etc., can solve the problems of difficult application of diamond powder, achieve good antibacterial performance and simple operation process , the effect of stable coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

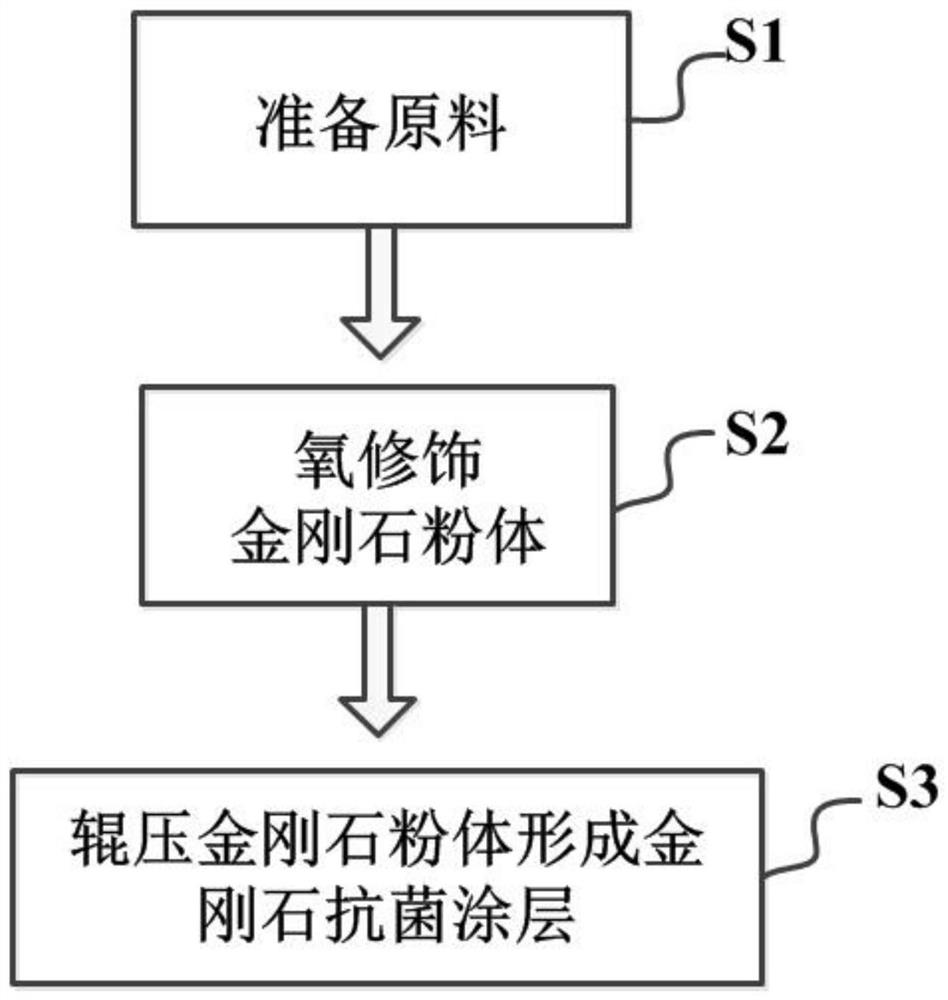

Method used

Image

Examples

Embodiment

[0029] Provide 5g of diamond powder, a rolling device and a 5cm×5cm pine wood substrate.

[0030] Put 5g of diamond powder into 500mL of hydrogen peroxide and heat treatment at 90°C for 10h. Then the diamond powder was transferred to a muffle furnace and annealed in air at a temperature of 600° C. for 10 h to obtain the final oxygen-modified diamond powder.

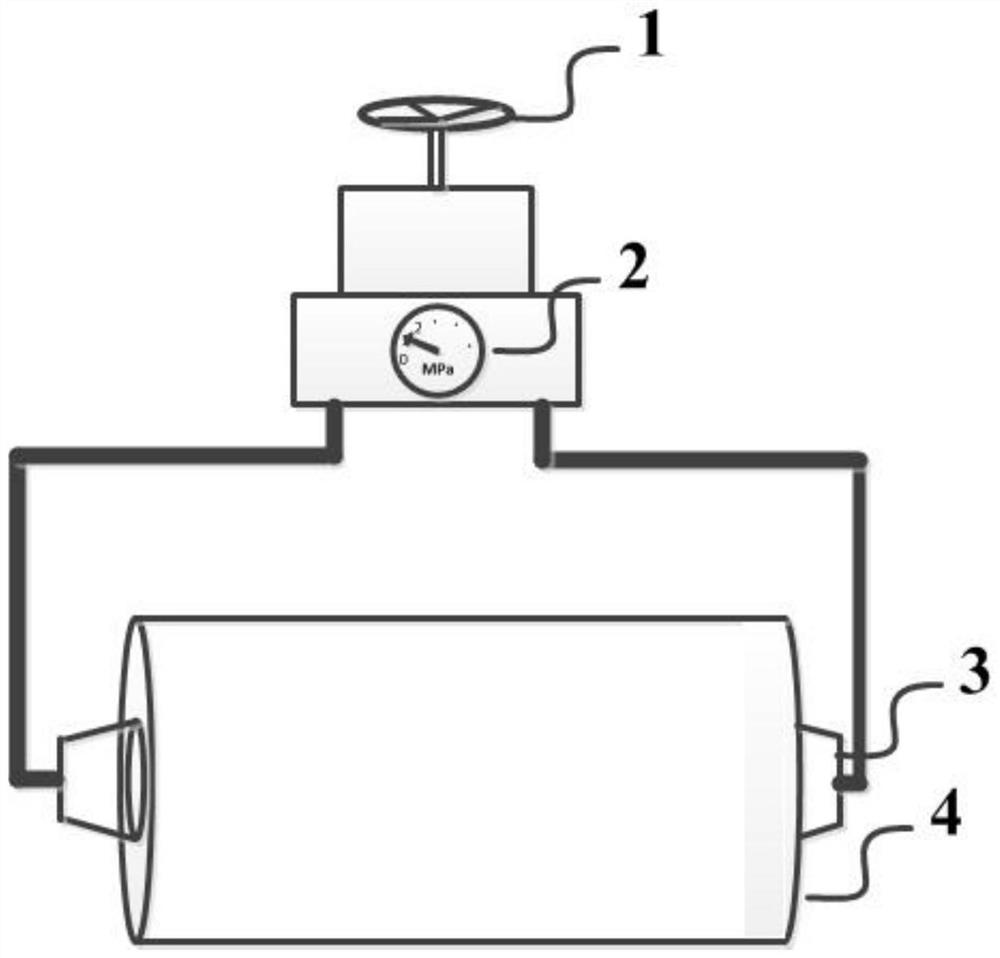

[0031] Lay the oxygen-modified diamond powder on the wooden board, set the pressure of 5.8MPa on the rolling device to repeatedly roll the diamond powder on the wooden board until the diamond powder is completely embedded in the surface of the wooden board. Therefore, the diamond antibacterial coating is obtained on the surface of the wood board, and the coating quality is stable and the antibacterial performance is good, which solves the problem that the diamond powder is difficult to apply.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com