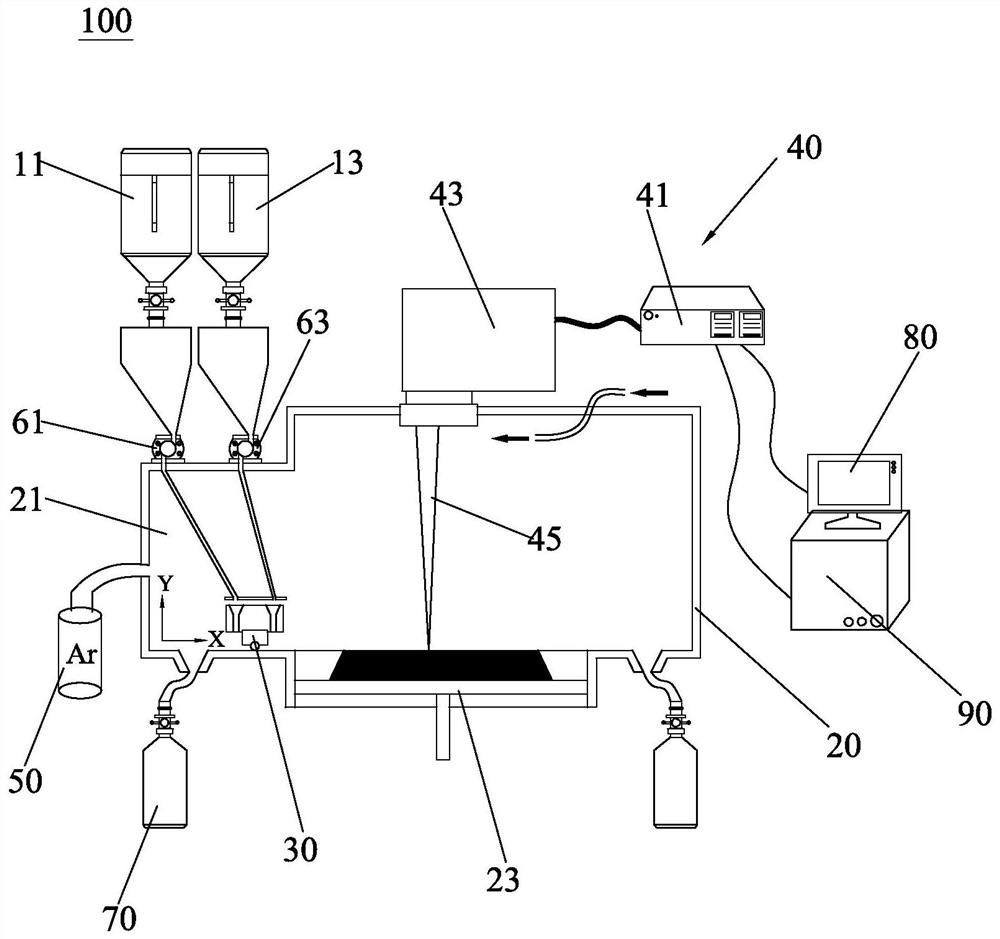

Aluminum-based boron carbide additive manufacturing method and device based on in-situ reaction

An in-situ reaction and additive manufacturing technology, which is applied in the direction of additive manufacturing, additive processing, and process efficiency improvement, can solve the problems of poor machining performance of ingots, and achieve the effect of avoiding machining processes and achieving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below through specific embodiments, but this does not constitute any limitation to the present invention.

[0032] A kind of aluminum-based boron carbide additive manufacturing method based on in-situ reaction of the present invention, its step comprises:

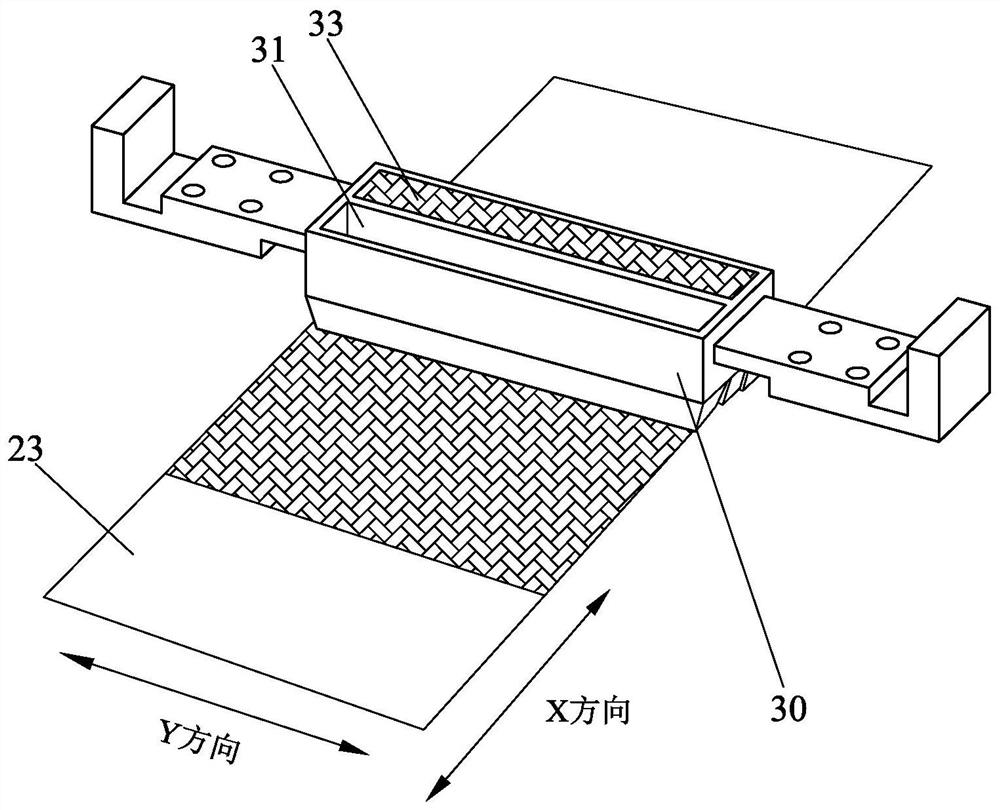

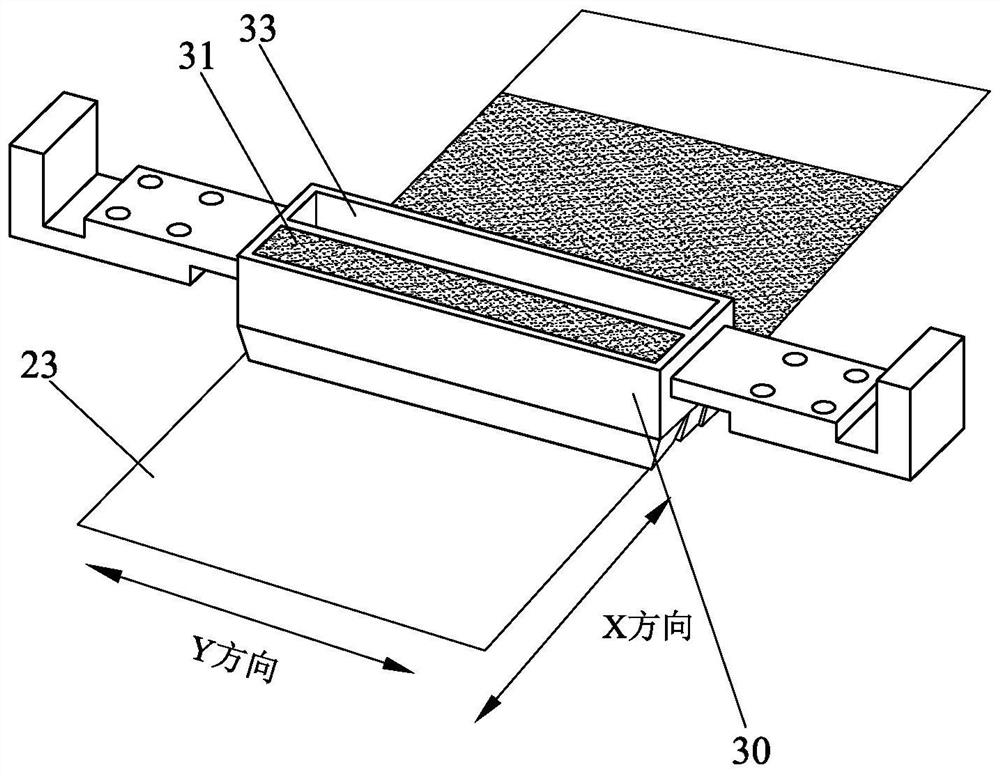

[0033] (1) Laying aluminum alloy powder on a laser-selected area under vacuum conditions, and emitting a laser beam to selectively melt the aluminum alloy powder in the laser-selected area to obtain an aluminum alloy layer;

[0034] (2) Lay the mixed powder of elemental carbon and elemental boron on the aluminum alloy layer, and emit a laser beam to selectively melt the mixed powder of elemental carbon and elemental boron, generate boron carbide in real time through in-situ reaction, obtain a boron carbide layer, and complete the carbonization Interlaminar fusion of boron layer and aluminum alloy layer;

[0035] (3) Step (1) and step (2) are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com