Environment-friendly drilling equipment for hardware plate machining

A kind of drilling equipment and an environment-friendly technology, which is applied in the field of drilling equipment for environment-friendly metal plate processing, can solve the problems of ambient air and noise pollution, the diffusion of drilling dust, and poor practicability, so as to avoid drilling errors , Reduce noise pollution, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

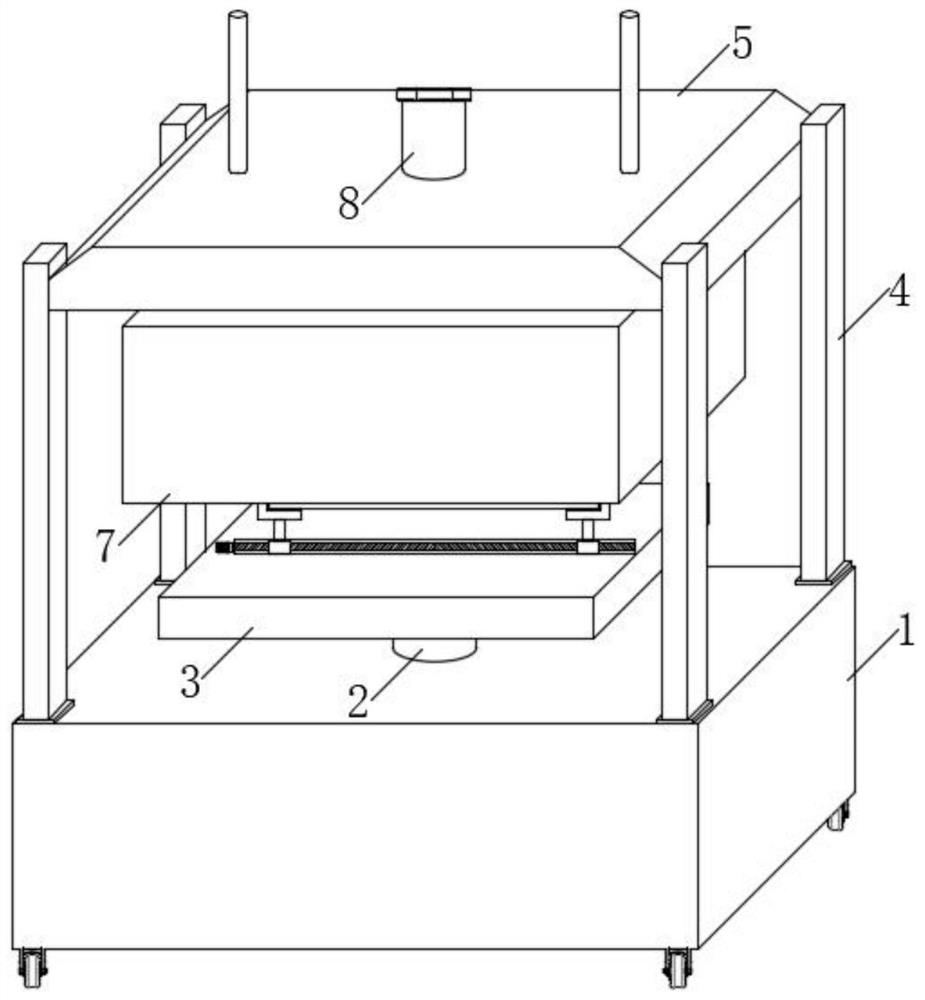

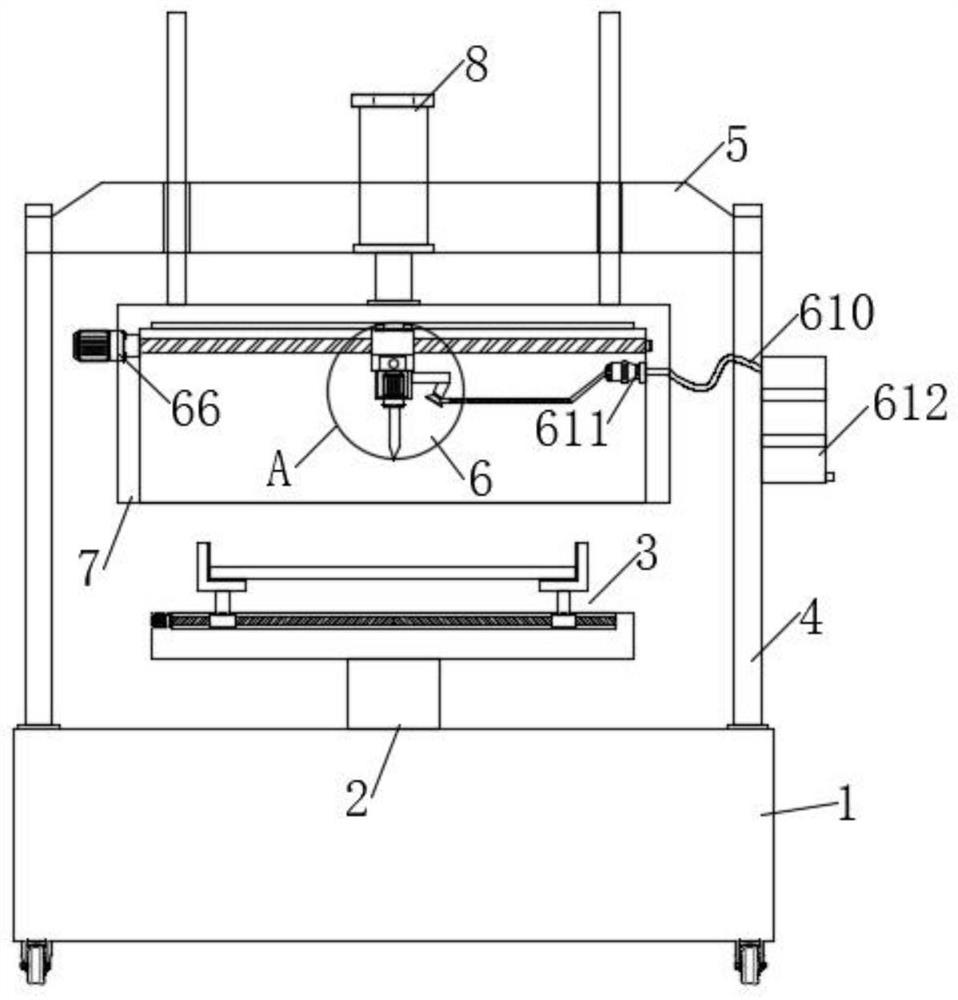

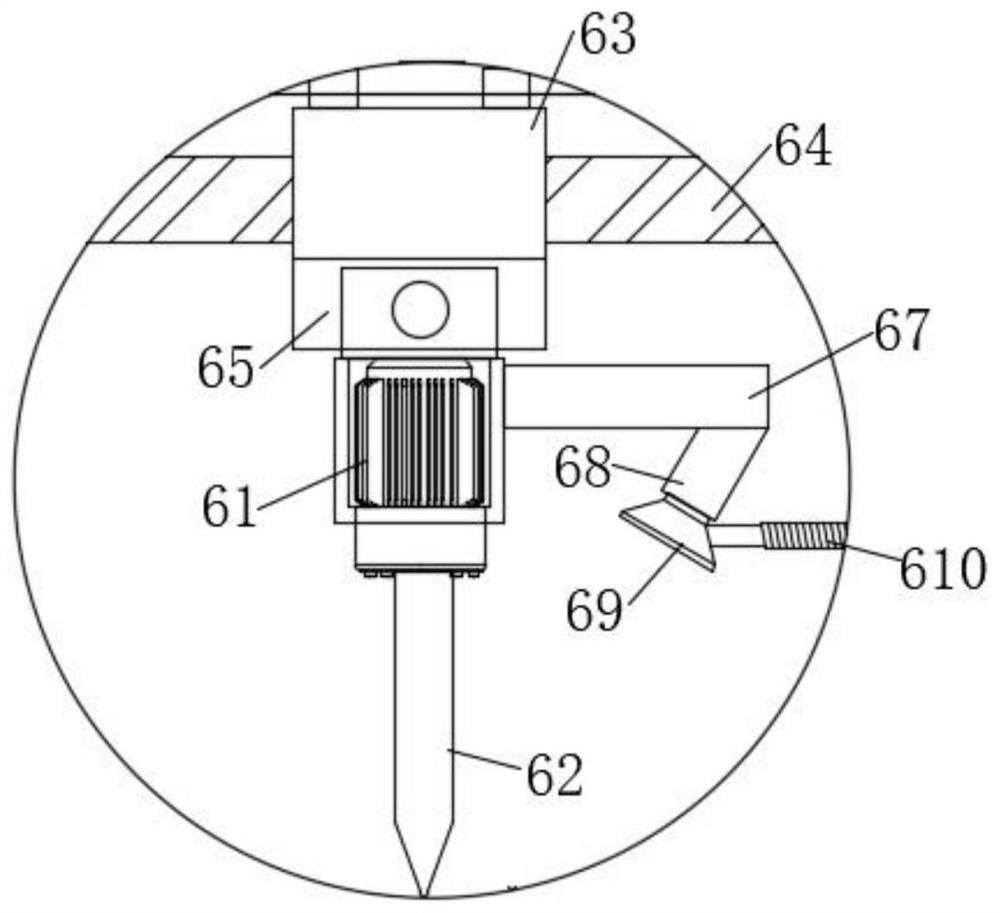

[0026] Such as Figure 1-6 As shown, this specific embodiment adopts the following technical solutions: an environment-friendly drilling equipment for processing metal panels, including a No. 1 workbench 1 and a support seat 2, and a support seat is fixedly installed on the top of the No. 1 workbench 1 2. The No. 2 workbench 3 is fixedly installed on the top of the support seat 2, and the No. 2 workbench 3 is composed of a bearing platform 31 and a clamping assembly, and the top of the bearing platform 31 is fixedly installed with a clamping assembly, so The four corners of the top of No. 1 workbench 1 are fixedly equipped with support frames 4, and the tops of the four support frames 4 are fixedly equipped with bearing top plates 5, and the tops of the load-bearing top plates 5 are fixedly equipped with hydraulic cylinders 8. The output end of the cylinder 8 is fixedly installed with the lifting protective cover 7 through the hydraulic rod, and the inside of the lifting prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com