Industrial automatic welding machine

An automatic welding machine and industrial technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of cumbersome operation and low welding efficiency, and achieve the effect of high welding efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

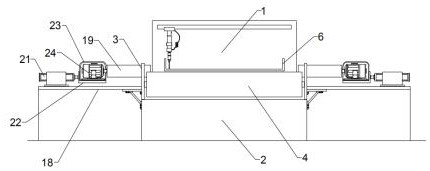

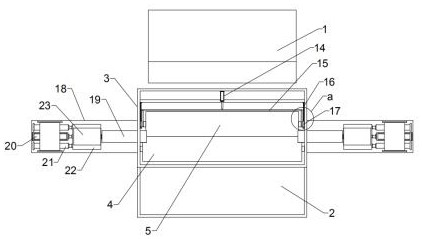

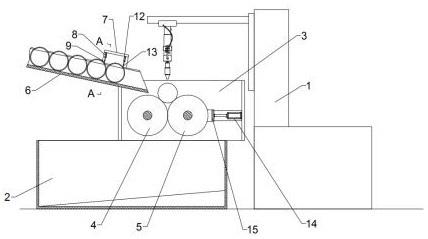

[0025] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6 As shown, all the electrical components in this case are connected with their corresponding power supply through wires through the personnel in the field, and the appropriate controller should be selected according to the actual situation to meet the control requirements. The specific connection and control sequence should refer to the following In the working principle described above, the electrical connections between the electrical parts are completed sequentially. The detailed connection means are well known in the art. The following mainly introduces the working principle and process, and does not explain the electrical control.

[0026] Embodiment: attached by specification Figure 1-6 It can be seen that this scheme includes the main body 1 of the stainless steel pipe head welding machine. The lower part of the welding head of the stainless steel pipe h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com