Automatic polyurethane color-matching stirring processing system and method

A processing system and processing method technology, applied in the field of machinery and equipment, can solve problems such as difficult to ensure accurate proportioning, dirty working environment, and difficult to dump cleanly, and achieve the effects of high precision, ensuring a healthy environment, and being easy to recycle and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

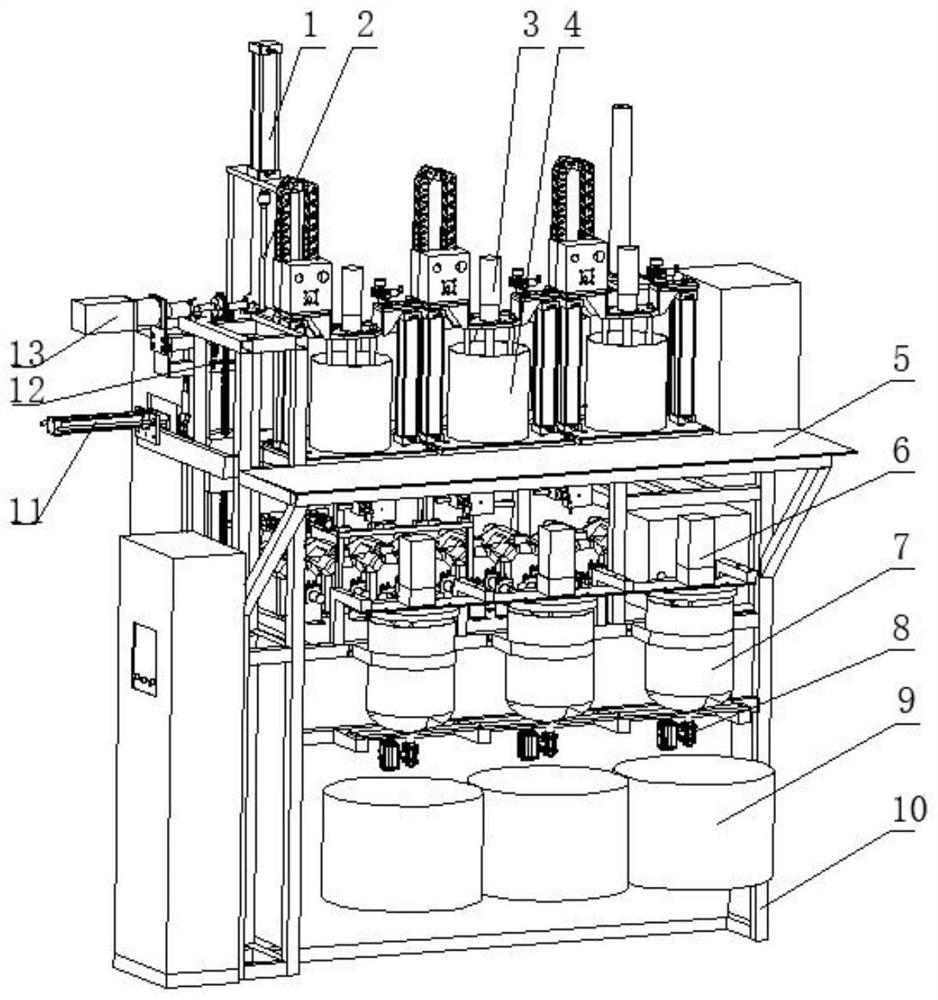

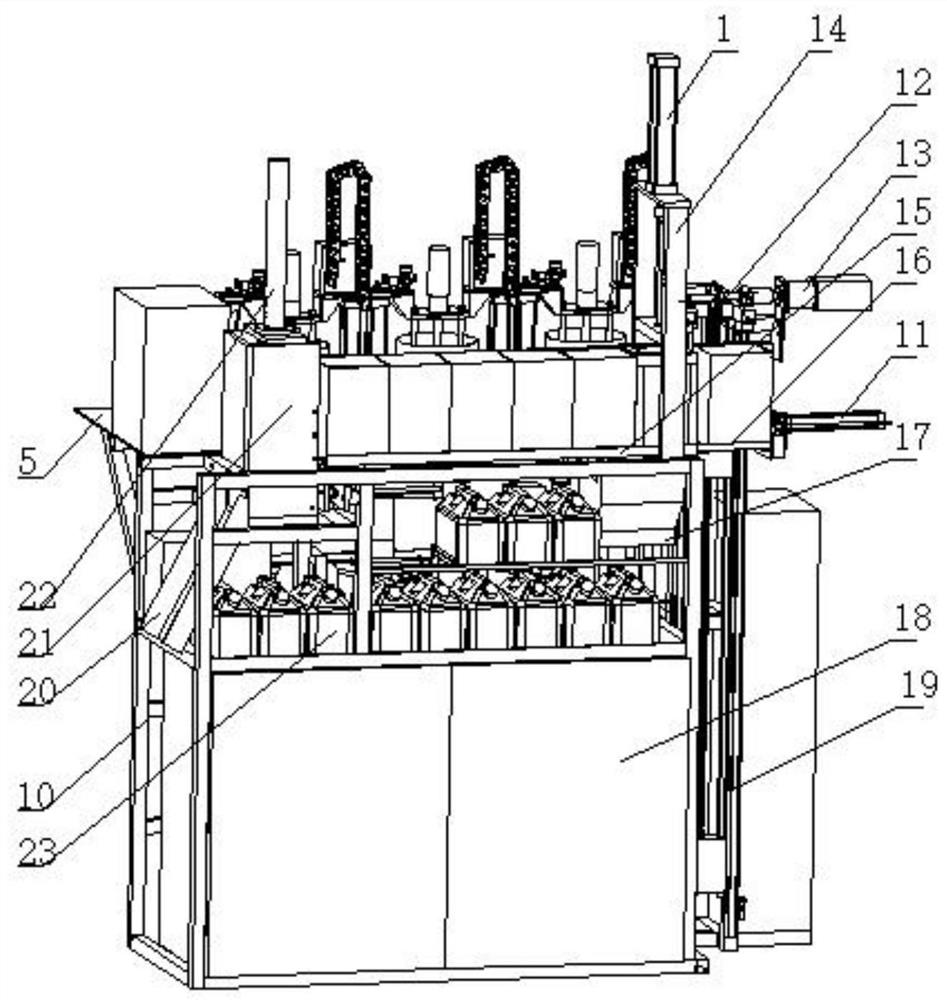

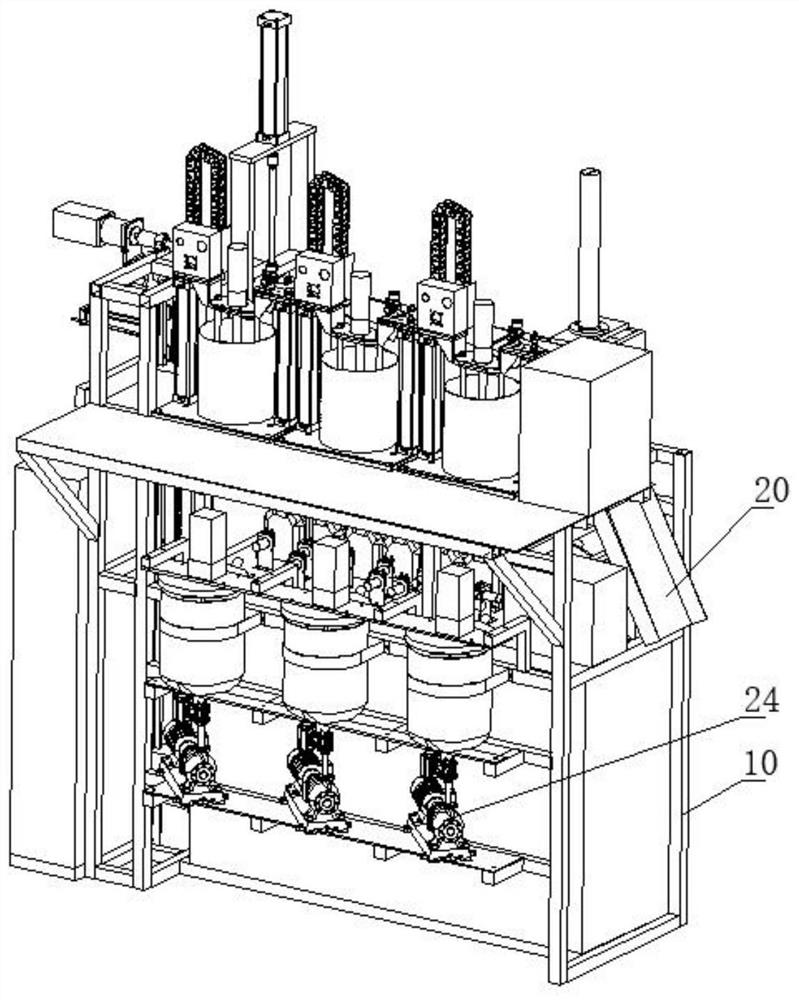

[0032] A polyurethane automatic color mixing and processing method, comprising a frame 10, an oven 18, a lifting device, a feeding station, a hopper, a mixing tank, a color paste bucket, and a batching bucket. The oven 18 is installed to be used for heating the bucket 25 that the main material is housed, and a hoisting device is installed on the lateral side of the frame, and the hoisting device can move up and down on the side of the frame;

[0033] Lifting device comprises lifting motor 13, hinge 12, supporting plate 16 and guide rail 19, and the lifting guide rail is fixedly installed in the frame inner side, and lifting guide rail upper limit sliding is installed supporting plate 16; The output s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com