Rotor wing brake control device with locking mechanism and method

A control device and rotor technology, which is applied in the field of rotor brake control devices, can solve the problems of difficult detection of hydraulic component failures, heavy weight of the hydraulic brake system, and large structural space occupied, and achieve convenient and efficient braking and brake release actions and accurate control , the effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in further detail below in conjunction with accompanying drawing:

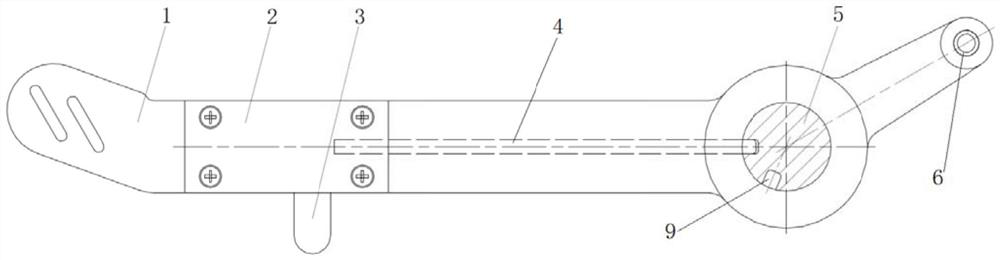

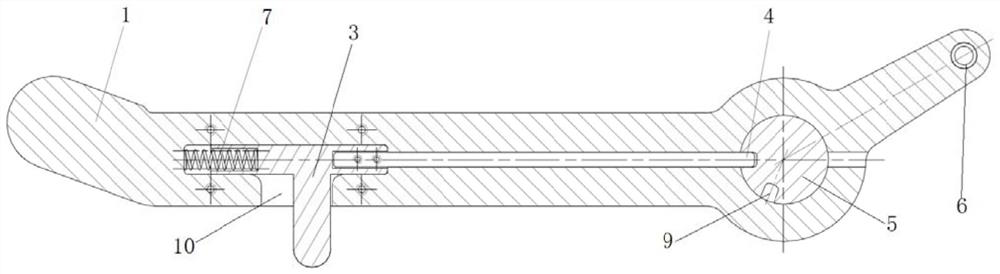

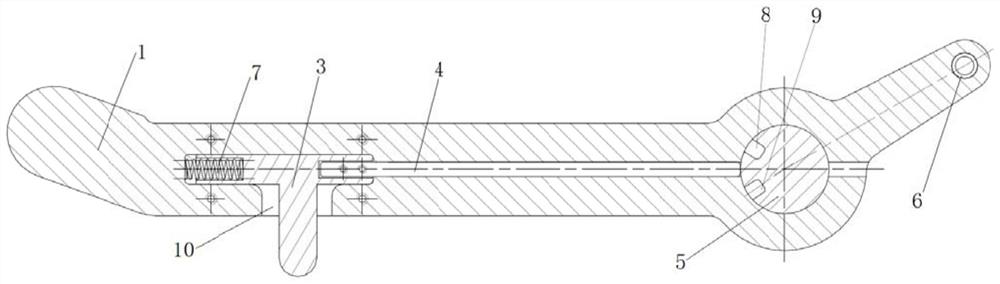

[0032] Such as figure 1 Shown is the rotor brake control device with a locking mechanism according to the present invention, which includes a brake handle 1 , a rotating shaft 5 and a slider 3 .

[0033] The front end of the brake handle 1 is a gripping end, which is used for the operator to hold and operate. The braking torque is directly transmitted to the operator by the brake handle 1, and the feedback is direct. A radial bushing 6 is arranged at the end of the brake handle 1 , and the transmission wire harness is arranged in the bushing 6 . The brake handle 1 is provided with a radial through hole, and the through hole is located near the end of the brake handle 1 . The rotating shaft 5 is arranged in the through hole and is rotationally connected with the brake handle 1 . The stroke of the transmission wire harness can be controlled by adjusting the distance b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com