Quenching equipment for leaf spring

A technology for leaf springs and quenching equipment, applied in quenching devices, heat treatment equipment, furnaces, etc., can solve the problems of flexible fine-tuning of unfavorable quenching liquid components, large volume design of quenching pools, and inability to ensure operational safety, etc. The effect of small floor area and high use intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

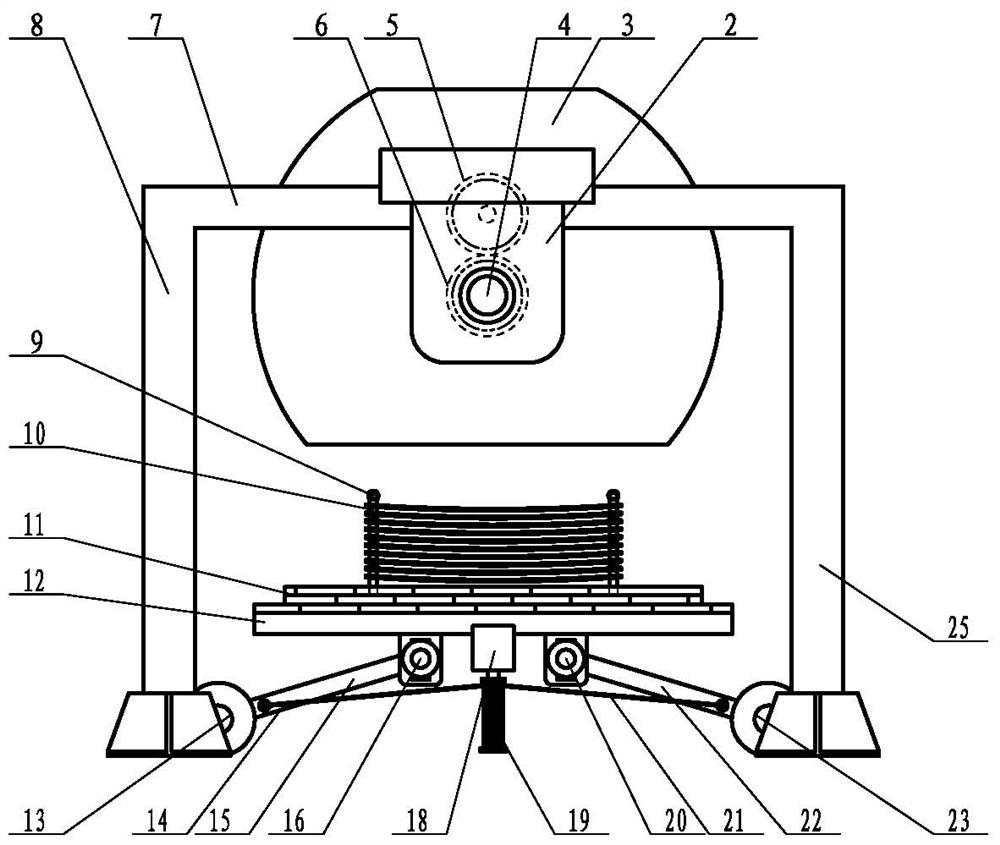

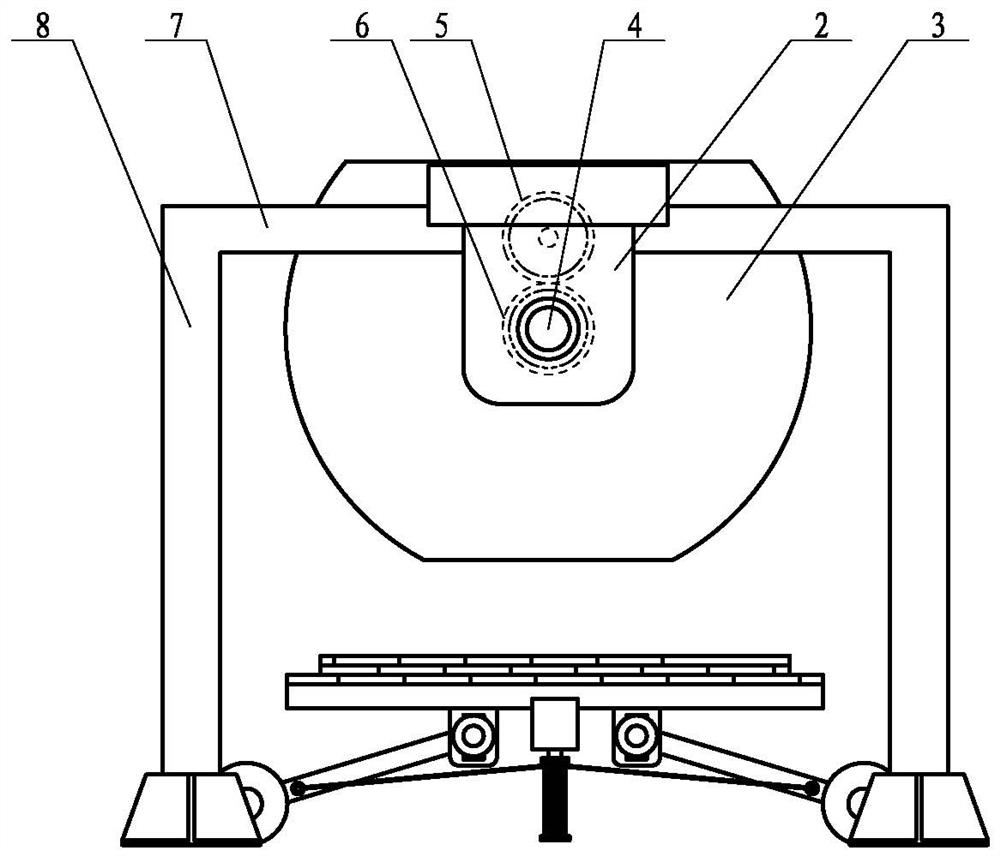

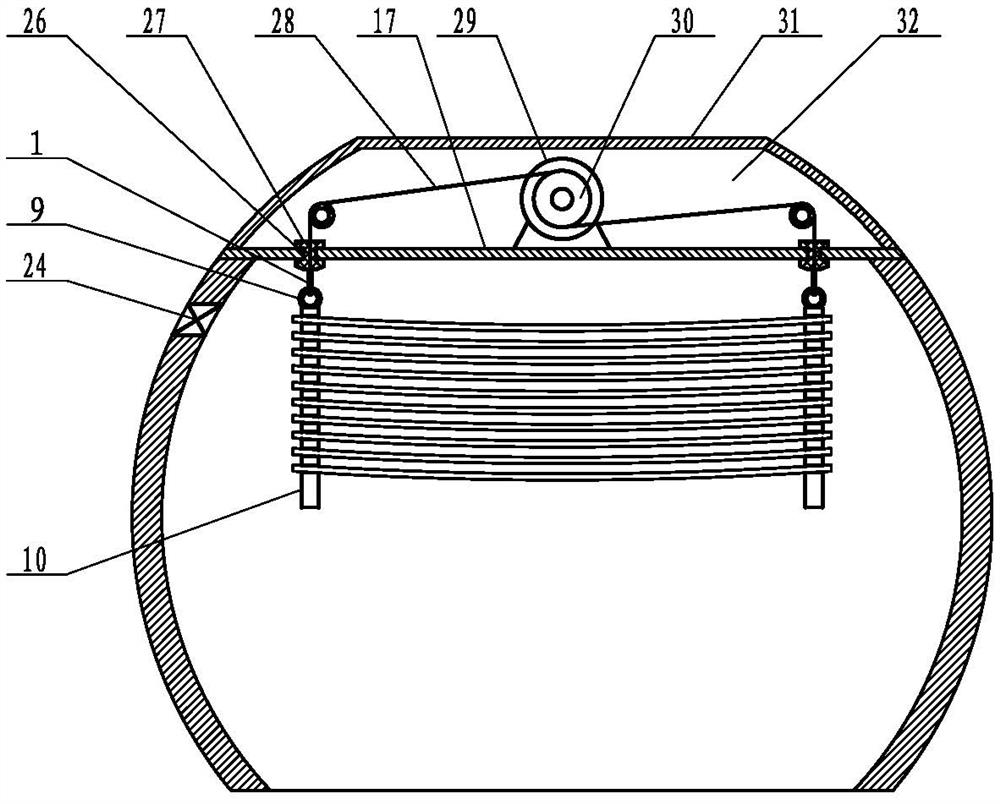

[0032] Such as figure 1 and 2 As shown, a kind of quenching equipment for leaf springs according to the present invention includes a gantry support, a flip-type quenching container, a quenching container rotating device and a leaf spring feeding car, and the gantry support includes a horizontal upper frame and at least four Columns, the upper frame is fixed on the ground through each column; the leaf spring feeding vehicle includes a lifting type running mechanism and a high-resistant vehicle plate, and the high-resistant vehicle plate is installed on the lifting type running mechanism and can be lifted The vertical lifting is driven by the type walking mechanism; the flip-type quenching container is installed on the upper frame of the gantry support through the quenching container rotating device; the quenching liquid guide tube is set above the gantry support, and the front end The fluid guide pump is connected to the liquid storage box; a liquid outlet hole is set on the s...

Embodiment 2

[0040] Such as Figure 6-9 As shown, the anti-off hook is convenient for the connection between the lower end of the pull rope and the lifting ring. The inner wall of the hook is provided with a groove, which is arc-shaped. The setting of the groove is used to lift the left or right lifting ring. The function of reaching the limit improves the safety during the hoisting process. The hoisting ring and the hook are integrally formed to improve the stability of the connection between the left hoisting ring or the right hoisting ring and the hook, thereby increasing the strength of the hook and improving the safety of the object during hoisting.

[0041] The side of the hook is welded with a fixed shaft, and one end of the fixed shaft is provided with a second baffle plate through a screw, and the surface of the second baffle plate is in contact with the surface of the limiting member. The setting of the second baffle is used to play a position-limiting effect on the position-lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com