Self-coupling tunnel lining detection device

A detection device and self-coupling technology, applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve problems such as potential safety hazards, manpower consumption, and staff fatigue, so as to ensure detection accuracy and easy disassembly Effect of work, good cushioning and protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

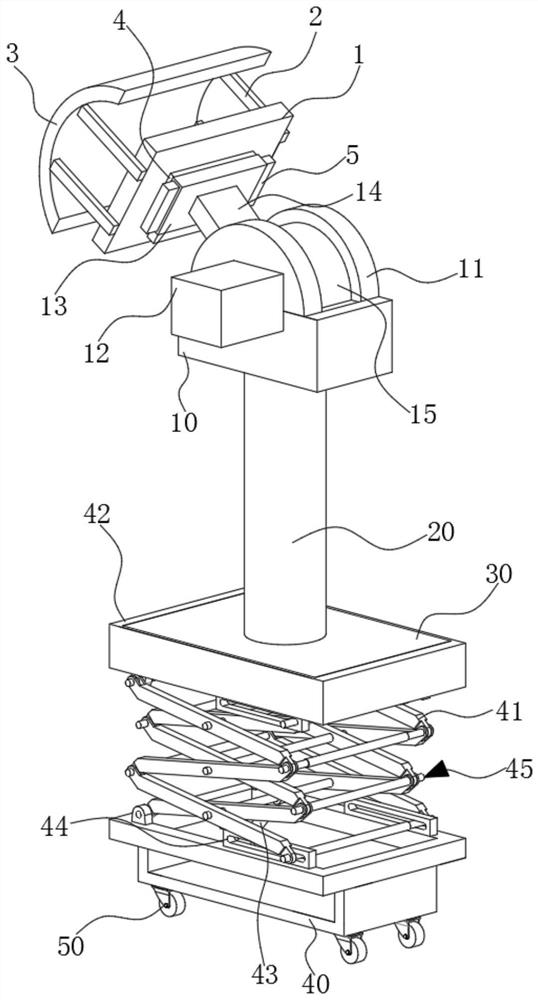

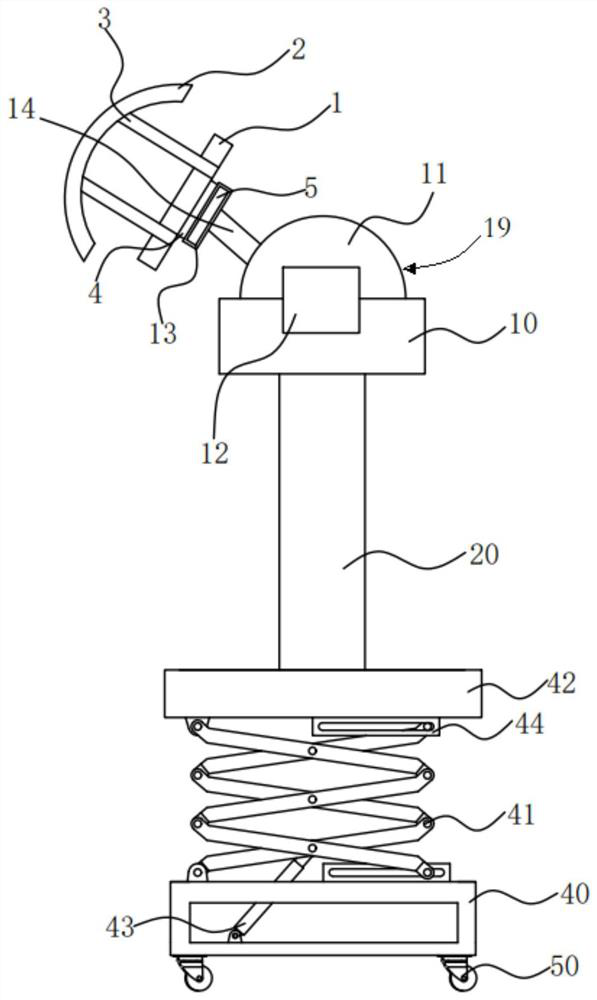

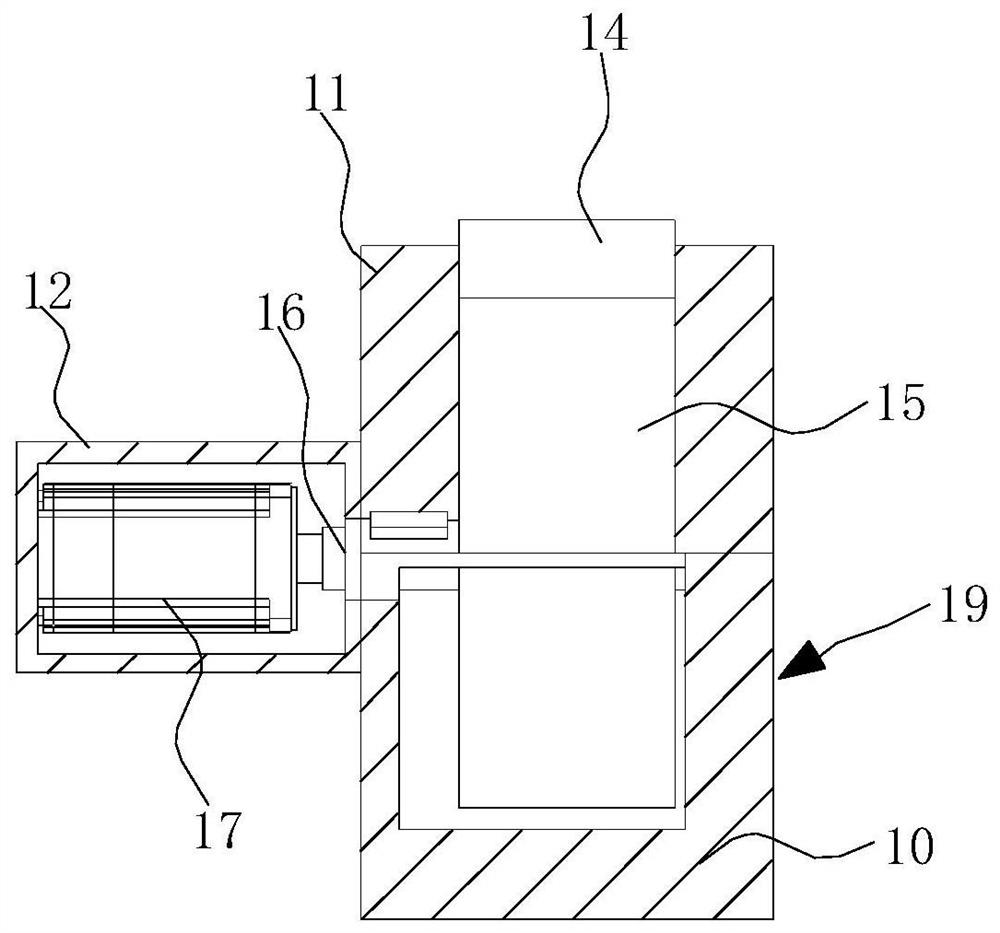

[0037] Embodiment: A self-coupling tunnel lining detection device provided by the present invention includes a detector support 1 and a mounting base 10, a support rod 20 is fixedly installed on the bottom surface of the mounting base 10, and a fixing plate is fixedly installed on the bottom surface of the support rod 20 30. In the process of tunnel lining detection, move the device to the position to be detected. In order to reach the height to be detected, start the hydraulic rod 43, and the output end of the hydraulic rod 43 drives the scissor lifting frame 41 to move vertically along the fixed point. Upward linear movement, at the same time one end of the scissor lift 41 moves along the sliding plate 44 to achieve the effect of supporting the lift. When it moves to an appropriate position, stop and start the hydraulic rod 43, and the hydraulic rod 43 can also support the scissor lift 41 Keep at a fixed height without changing. When the height is adjusted, start the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com