Design method of high-pressure-ratio multistage axial-flow type hydraulic turbine

A technology of hydraulic turbine and design method, applied in the field of rotating fluid machinery, to achieve the effect of ensuring safety margin, improving efficiency and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

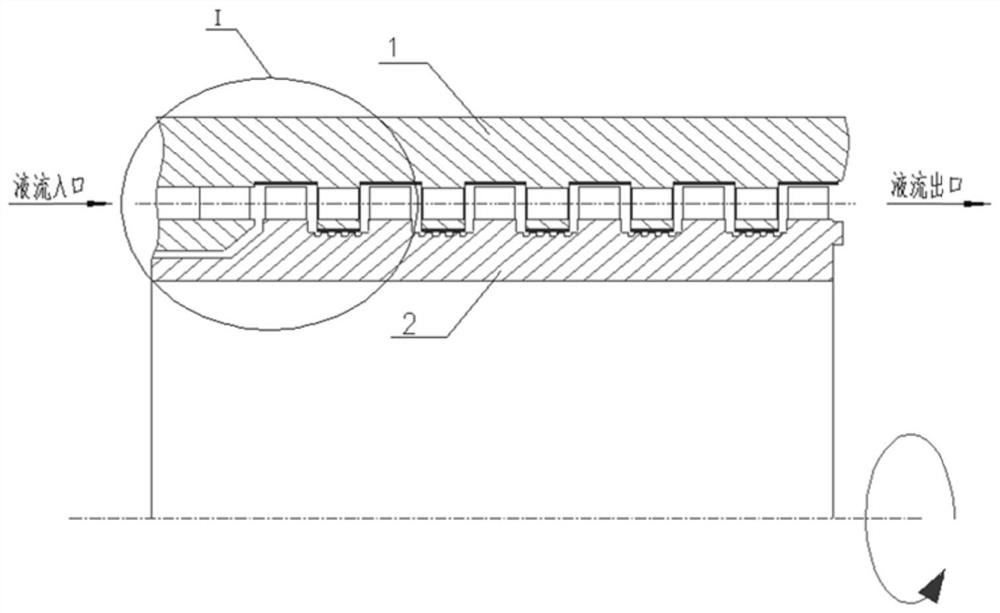

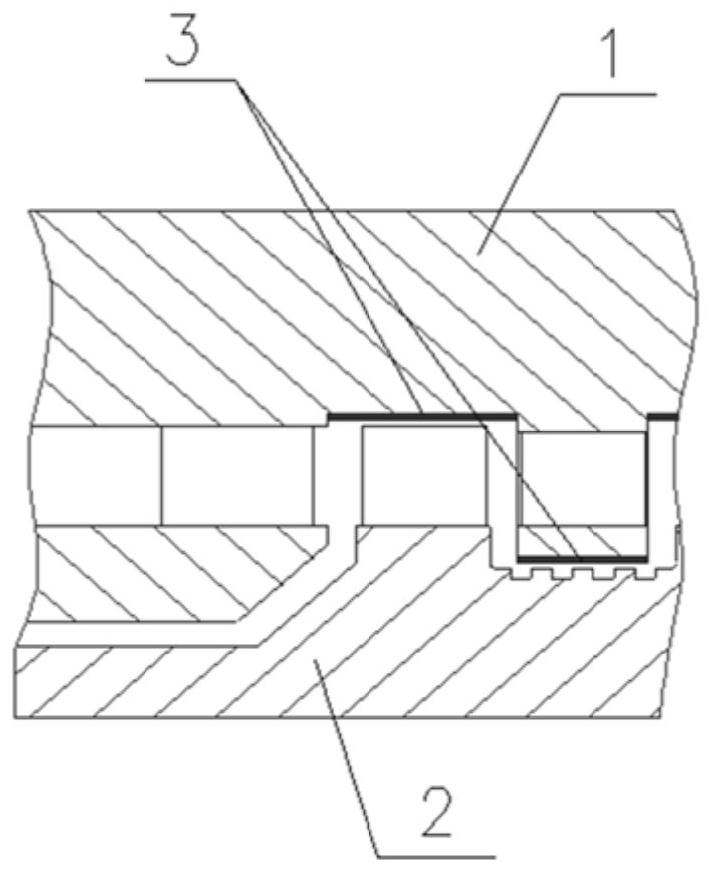

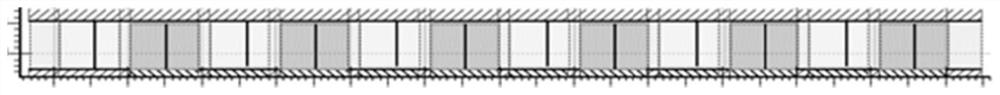

[0034] A high-pressure ratio multi-stage axial-flow hydraulic turbine design method, adopting 6-stage axial-flow design, designing meridian flow channels through liquid working fluid to ensure that the flow velocity triangle of liquid working fluid at each level is the same, and determining the matching method between stages, Ensure that the output power is evenly distributed among the stages, and the internal stress of the rotor blades is evenly distributed, thus ensuring the safety margin of the rotor blades at all levels. The improvement of machining efficiency and the reduction of machining difficulty.

[0035] The specific steps of the multi-stage axial-flow hydraulic turbine design method are as follows:

[0036] (1) Runner design according to the type of working fluid;

[0037] Wherein, the type of working medium is liquid working medium, and the flow channel is designed as a meridian flow channel of equal cross section, which converts the pressure potential energy of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com