Battery cell aging equipment and aging control method

A control method and cell technology, applied in secondary battery manufacturing, electrolyte storage battery manufacturing, battery assembly machine, etc., can solve problems such as prolonging battery production cycle, reducing production efficiency by aging time, increasing production process cost, etc. The effect of battery injection volume, improving the efficiency of absorbing electrolyte, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings. For the convenience of description, the definitions of directions such as up, down, left, and right in this application are only for the convenience of clearly describing the structure of the device, and do not necessarily It is limited to the actual position of the device in the process of production, use, sales, etc. The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

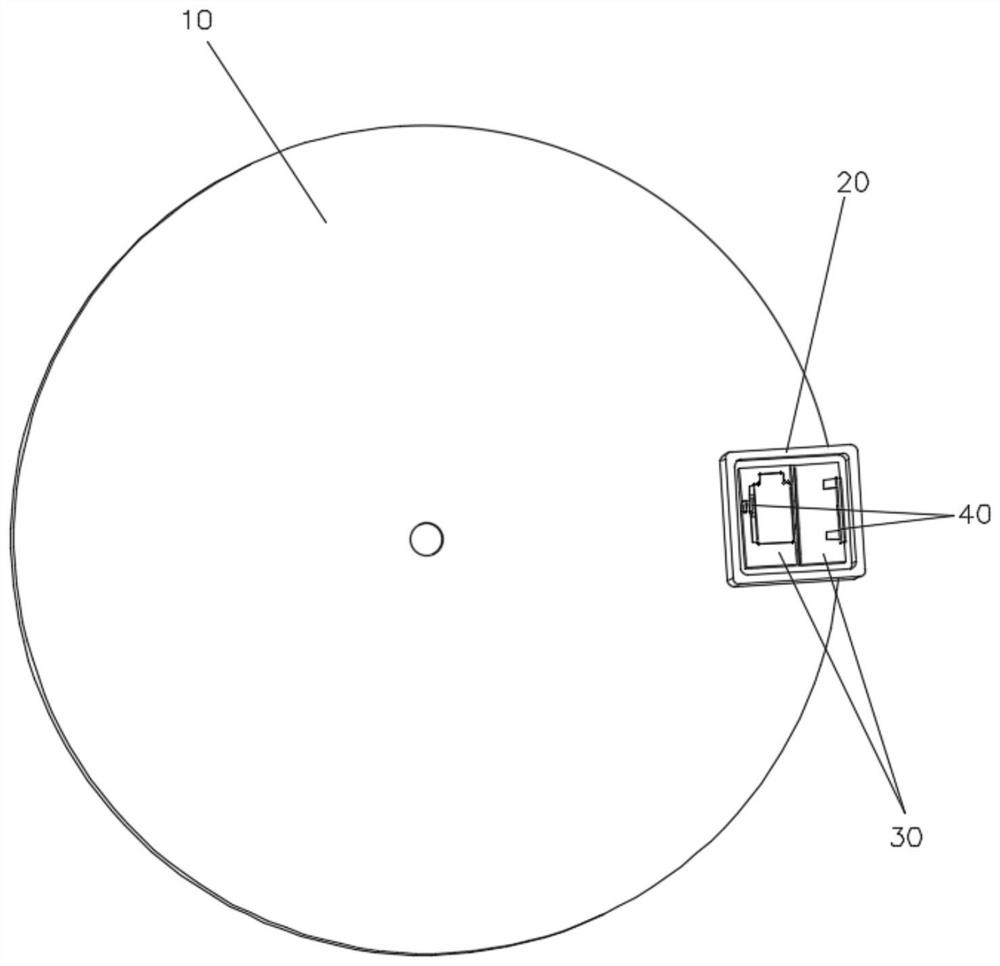

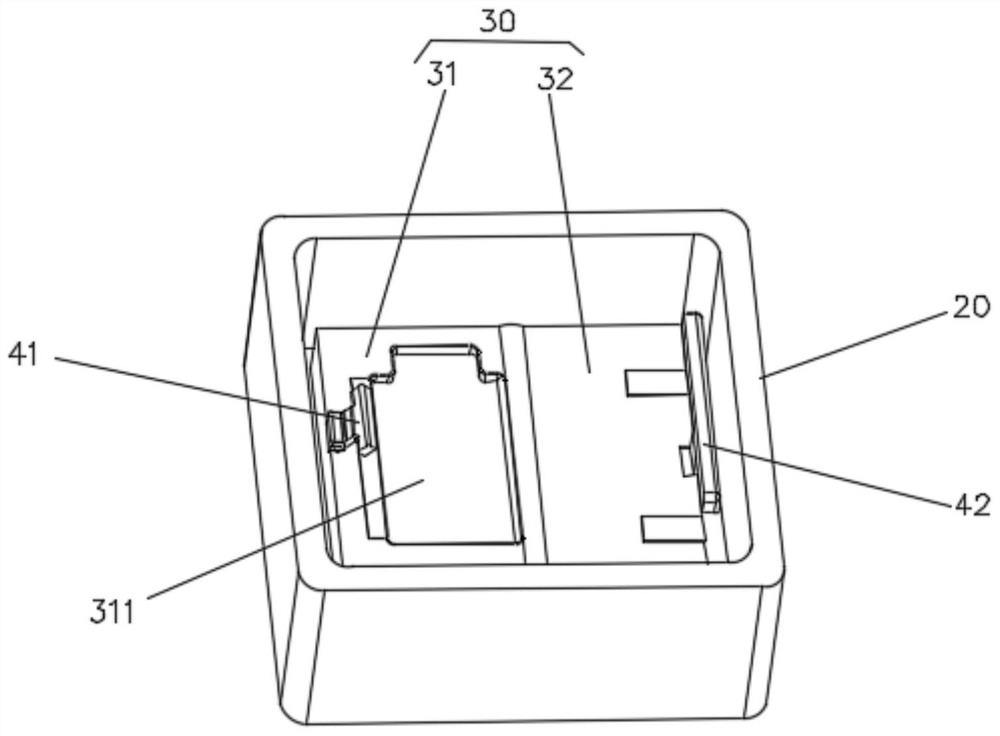

[0024] Such as figure 1 As shown, the cell aging equipment provided in this embodiment includes a rotating base 10 , a cell placement box 20 , a cell carrier 30 and a cell clamping mechanism 40 . The rotating base 10 is a turntable, which rotates at a constant or variable speed at different speeds under the control of a battery revolution drive mechanism (such as a motor, etc., not shown in the figure)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com