A radial double-winding switched reluctance motor for electric vehicles and its power converter

A switched reluctance motor and power converter technology, applied in electric vehicles, electric components, AC motor control, etc., can solve the problem of not improving the power density and efficiency of the motor, increasing the torque and speed regulation range, increasing the structure or winding complexity In order to improve the motor efficiency, shorten the excitation circuit, reduce the supersaturation of the flux linkage and mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

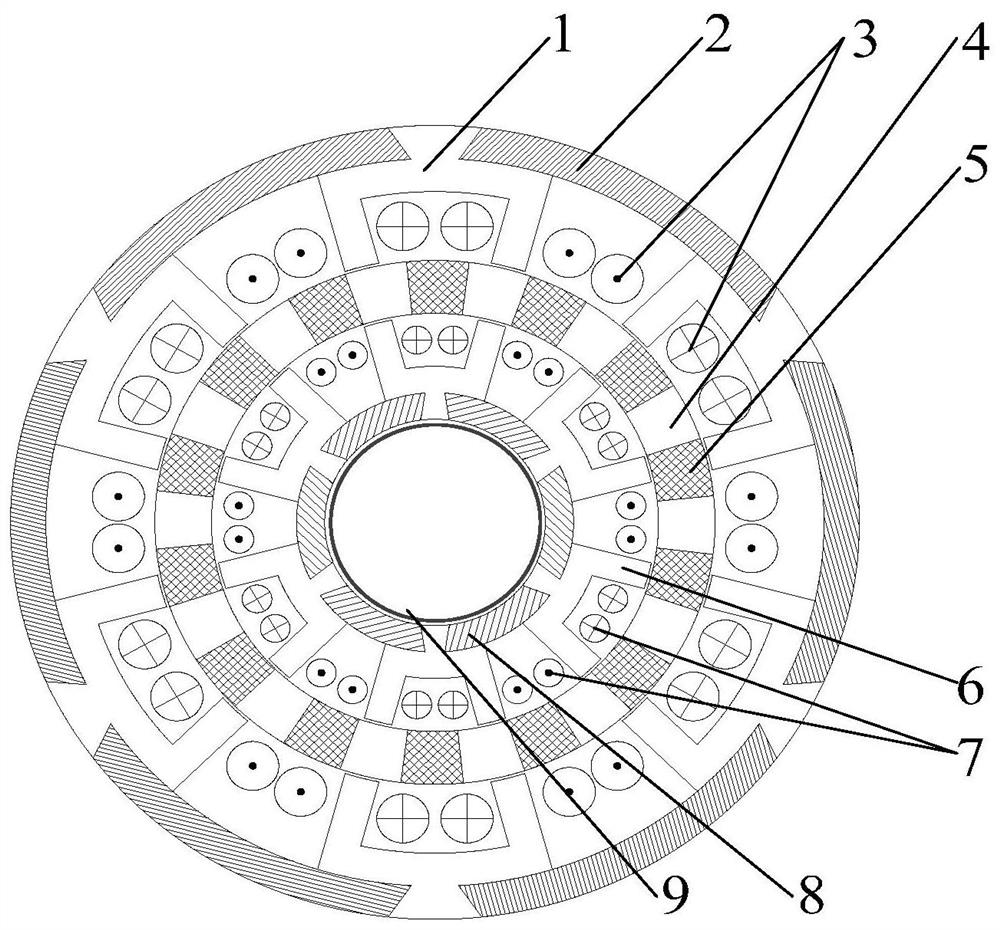

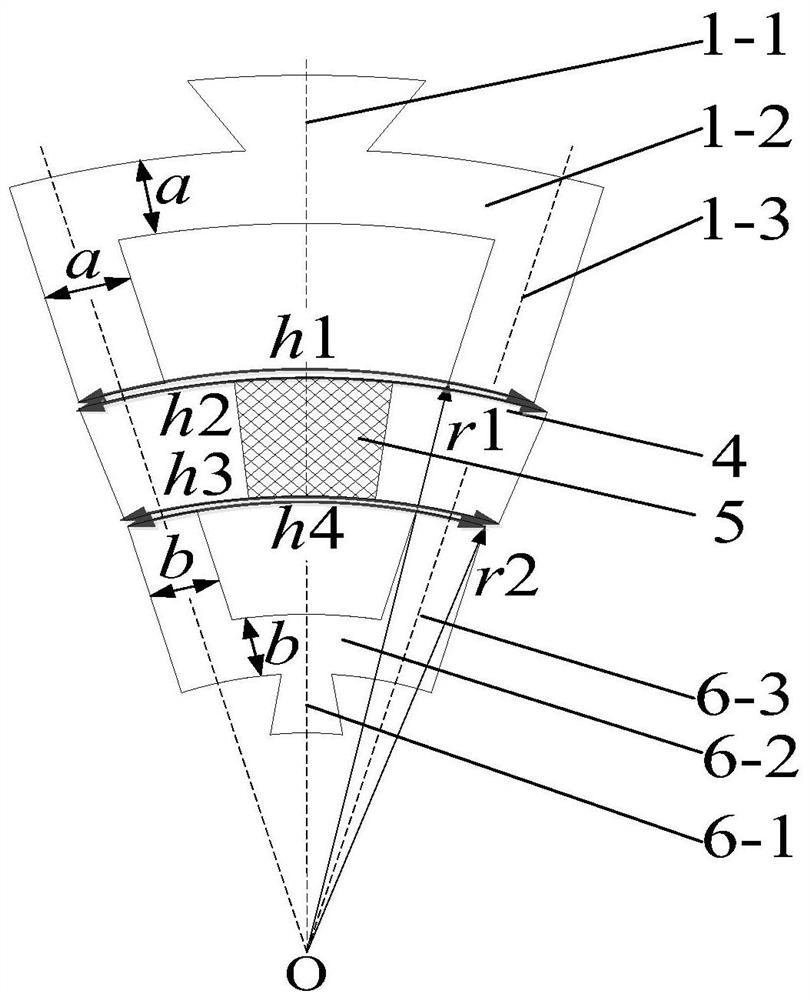

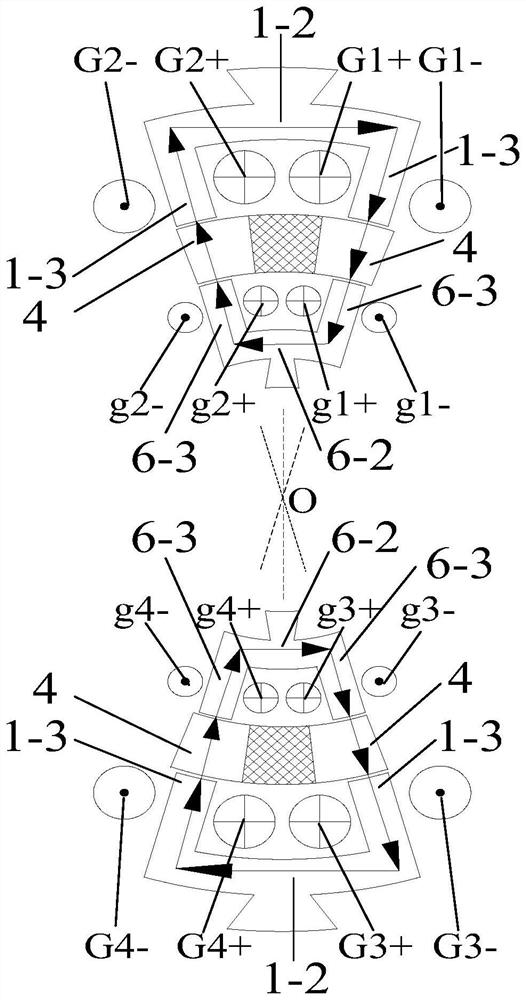

[0026] see figure 1 , a radial double-winding switched reluctance motor for an electric vehicle according to the present invention, comprising an outer segmented stator 1, a non-magnetically conductive outer shell 2, an outer winding 3, a trapezoidal segmented rotor 4, a non-magnetically conductive trapezoidal block 5, Inner block stator 6 , inner winding 7 , non-magnetic inner shell 8 and rotating shaft 9 . The outermost part is the outer block stator 1 and a non-magnetic outer casing 2, the non-magnetic outer casing 2 is cylindrical, and the side wall of the non-magnetic outer casing 2 is evenly embedded in the circumferential direction s Outer block stator 1, N s The structures of the two outer segmented stators 1 are exactly the same, the outer diameter of the outer segmented stator 1 is equal to the outer diameter of the non-magnetic conduction outer shell 2, but the inner diameter is smaller than the inner diameter of the non-magnetic conduction outer shell 2. Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com