Cold trap device and diffusion furnace equipment

A diffusion furnace and cold trap technology, applied in mechanical equipment, lighting and heating equipment, condensation traps/cold partitions, etc., can solve the problems of semiconductor device production capacity impact, long time consumption, etc., to improve maintenance cycle and machine productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

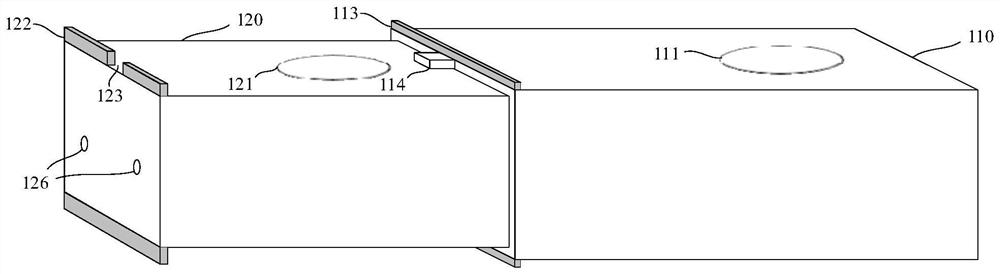

[0034] It can be seen from the background art that the existing cold trap device has the problem that the maintenance process takes a long time.

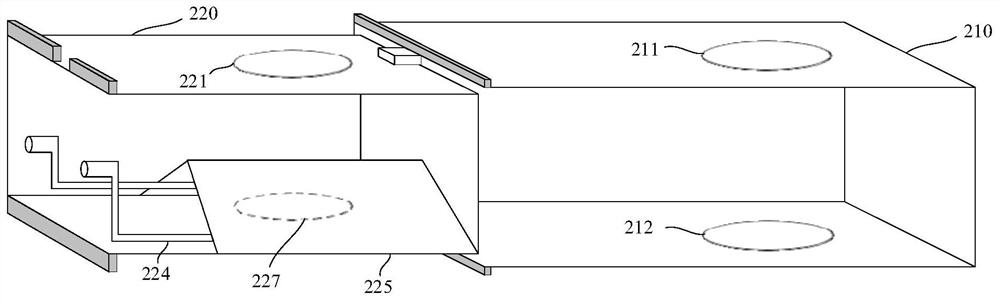

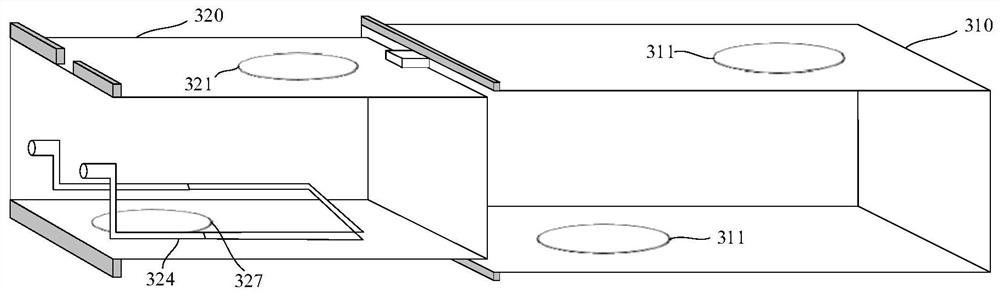

[0035] In order to solve the above problems, an embodiment of the present invention provides a cold trap device. An inner shell is also provided in the outer shell. The inner shell and the outer shell have an air inlet and an air outlet respectively, and are used to provide a cooling pipe for a low-temperature environment. The passage is located within the inner housing, allowing the by-products to condense on the inner housing walls. When the rate of capturing reaction by-products in the inner shell is lower than the preset level, the entire inner shell and the cooling pipeline located in the inner shell can be directly taken out and replaced with a new inner shell and cooling pipeline, thereby shortening the cooling time. The maintenance of the well device is time-consuming, and the productivity of the machine is improved.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com