Busbar bending tool

A busbar and tooling technology, applied in the field of busbar bending tooling, can solve the problem that the busbar bending tooling is not easy to ensure the busbar forming quality and other problems, and achieve the effects of simple structure, guaranteed forming quality and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

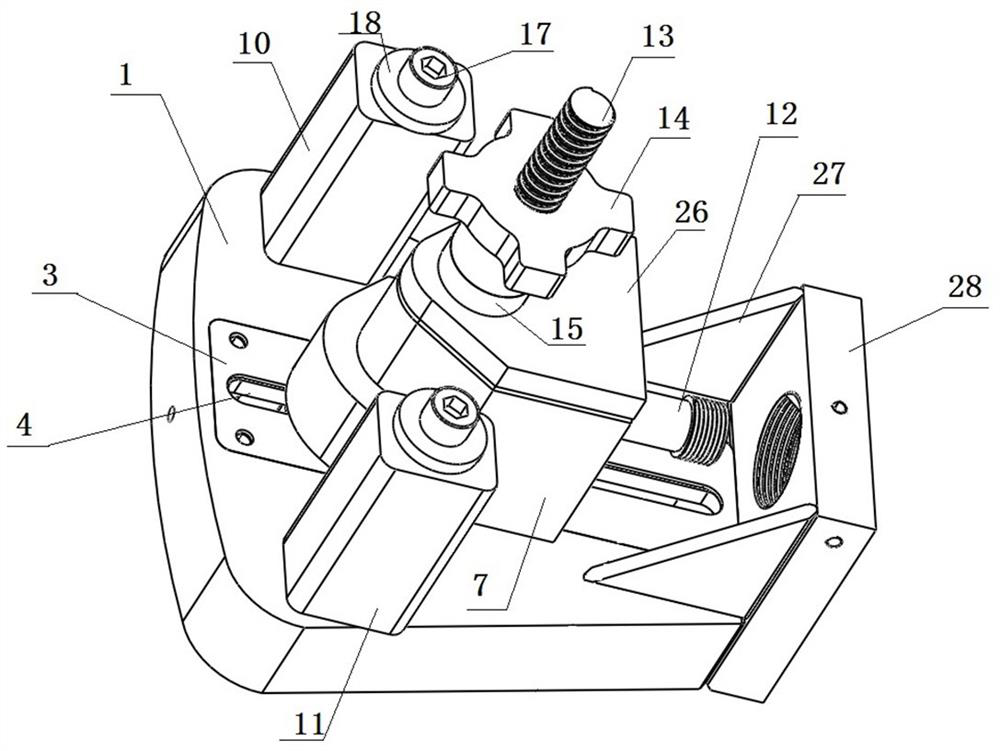

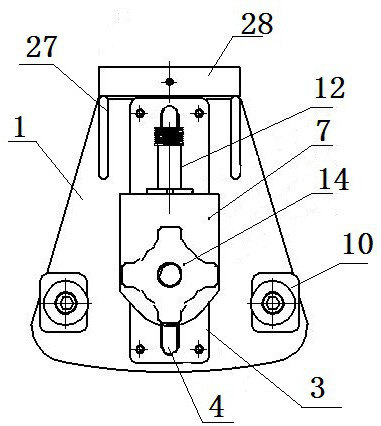

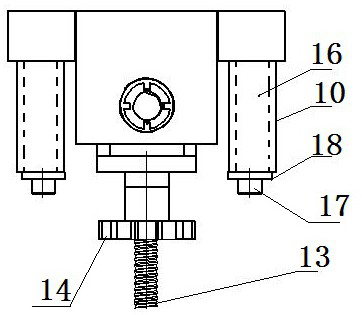

[0044] The busbar bending tooling of the present invention mainly performs bending operations on the transformer coil outlet busbars, such as Figure 1 to Figure 8 As shown, the busbar bending tool includes a base 1, and the base 1 has a sliding mating surface for slidingly mating with the busbar to be bent. In this embodiment, the base 1 includes a plate body and a slide plate 3 fixed on the plate body and extending along the length direction of the plate body, wherein the plate body is made of aluminum alloy, which is light in weight, and the slide plate 3 is made of stainless steel material with a smooth surface In this way, the friction between the busbar and the base can be reduced during the bending process of the busbar, thereby reducing scratches on the busbar and helping to protect the busbar. Such as Figure 7 and Figure 8 As shown, the plate body is provided with a strip-shaped sliding hole extending along its length direction and a slider 2 guided and slidably a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com