Low-silicon inoculant and preparation method thereof

An inoculant and ferrosilicon technology, which is applied in the field of cast iron, can solve problems such as the inability to realize the reuse of recycled materials and iron filings, the inability to use a large amount of recycled materials and iron filings, and the inability to reduce costs, so as to ensure the inoculation effect and reduce silicon Content, the effect of increasing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The application also provides the preparation method of the low-silicon inoculant, comprising the following steps:

[0026] Melting pig iron and ferrosilicon to obtain a melt, adding one or more of calcium, aluminum, barium, strontium and zirconium to the melt for smelting, cooling and solidifying, and breaking to obtain a low-silicon inoculant.

[0027] The invention controls the silicon content of the inoculant at 30-60% and introduces other trace metal elements to be used as the inoculant for the inoculation treatment of molten iron. The inoculation effect is equivalent to that of the traditional inoculant. Appropriate increase means that a large amount of recycled materials and iron filings can be used. Compared with traditional inoculants, the inoculant of the present invention has the characteristics of low silicon, low melting point and easier melting, and is more suitable for the situation where the original molten iron has higher silicon and lower molten iron t...

Embodiment 1

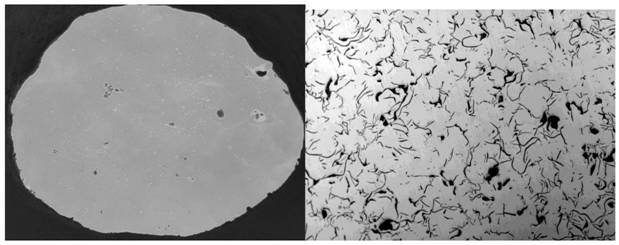

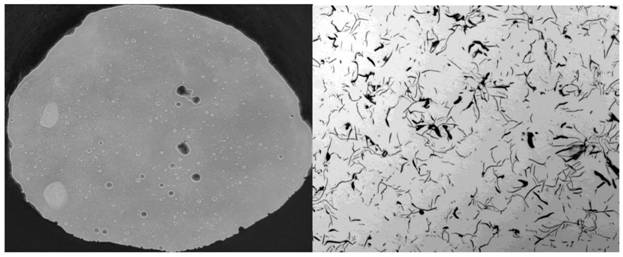

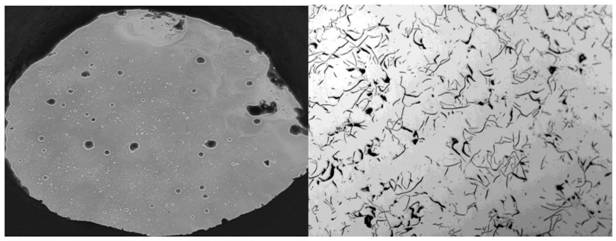

[0032] Produce a kind of inoculant composition as above-mentioned method and be: Si 58.59wt%, Ba 1.15wt%, Ca 1.24wt%, Al 1.11wt%, surplus Fe; Particle size 0.2~0.8mm, try out in certain factory, inoculation effect is good ( Such as Figure 1 ~ Figure 4 shown), and the usage of returned material and iron filings increased by 15% in the production process.

[0033] figure 1 The inoculant prepared for this example is at the inoculation amount of 0.2%, 1429°C, the liquid level state and the corresponding graphite morphology after 19s after inoculation; figure 2 It is the liquid surface state and the corresponding graphite morphology of the traditional inoculant at the inoculation amount of 0.2%, 1419°C, 21s after inoculation; image 3 The inoculant prepared for this example is at the inoculation amount of 0.4%, 1418°C, the liquid level state and the corresponding graphite morphology after 22 seconds after inoculation; Figure 4 It is the state of the liquid level of the tradit...

Embodiment 2

[0035] Produce a kind of inoculant composition in the above-mentioned way and be: Si 42.62wt%, Sr 1.24wt%, Ca 1.15wt%, Al 1.07wt%, surplus Fe; Particle size 0.2~0.8mm, try out in certain factory, effect is good (as Table 1), and in the production process, the amount of recycled materials and iron filings increased by 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com