Screw and rubber cap assembling device and method

A technology for assembling devices and rubber caps, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult clamping and assembly, soft rubber caps, etc., and achieve the effects of improving efficiency, facilitating processing, and preventing falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

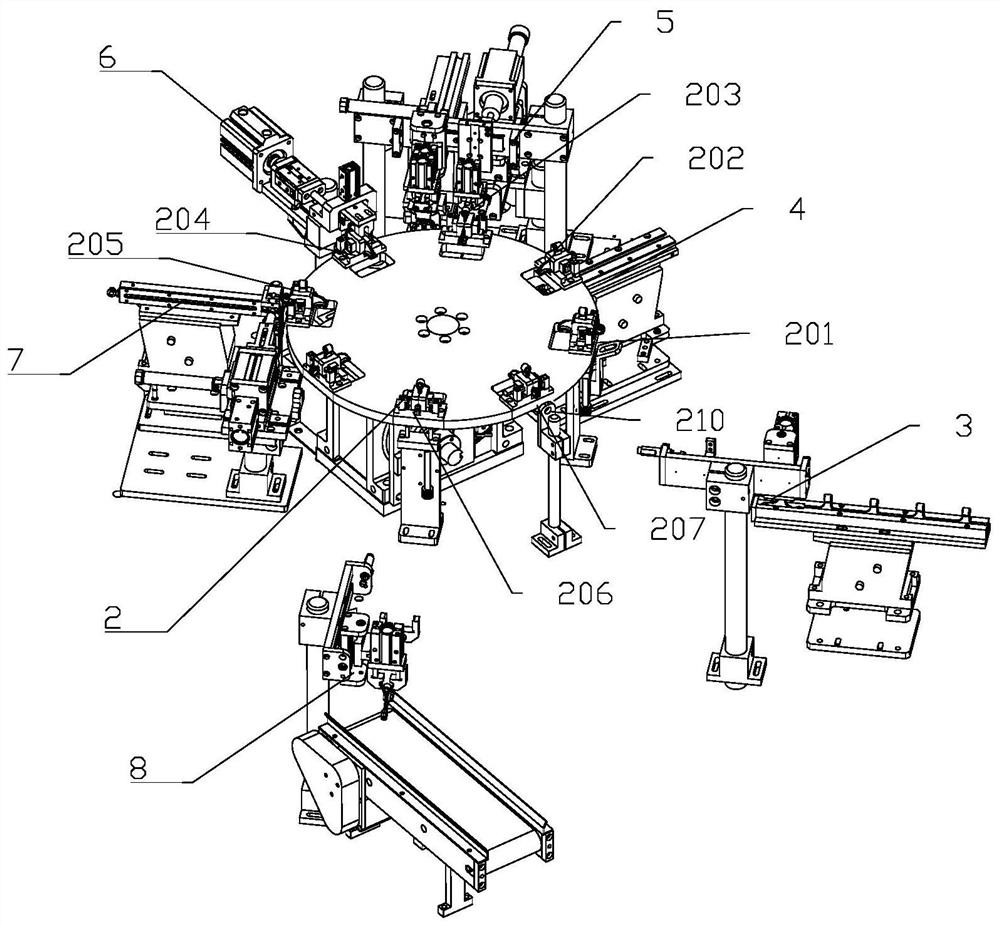

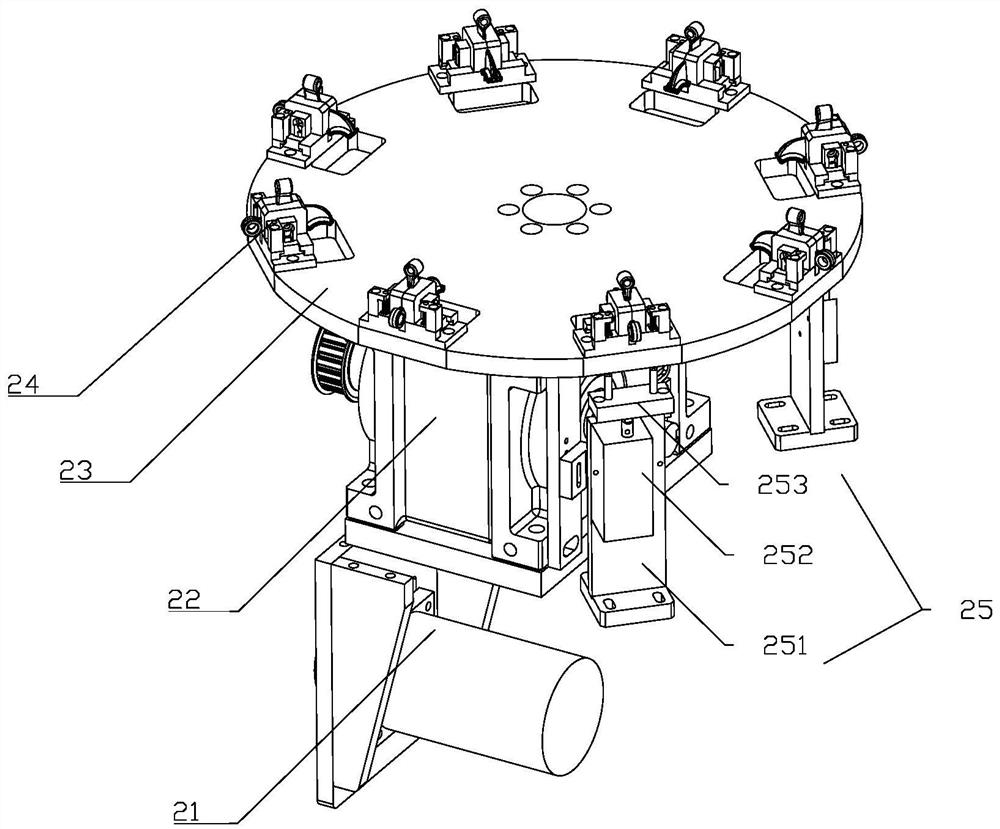

[0026] Such as figure 1 As shown, a doorstop assembly machine includes a frame and a fixture rotating device 2 installed on the frame, a substrate feeding device 3, a foot assembly device 4, a screw assembly device 5, a rubber cap assembly device 6, a rotating sleeve Device assembly 7 and finished product unloading device 8; The described jig rotating device 2 is positioned at the center of the frame, and the jig rotating device 2 is in the shape of a circle, and a week of the jig rotating device 2 is provided with a plurality of stations, respectively for the upper The material station 201 is the first assembly station 202, the second assembly station 203, the third assembly station 204, the fourth assembly station 205, the blanking station 206 and the detection station 207; the substrate feeding device 3 corresponds to the upper The material station 201, the foot assembly device 4 corresponds to the first assembly station 202, the screw assembly device 5 corresponds to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com