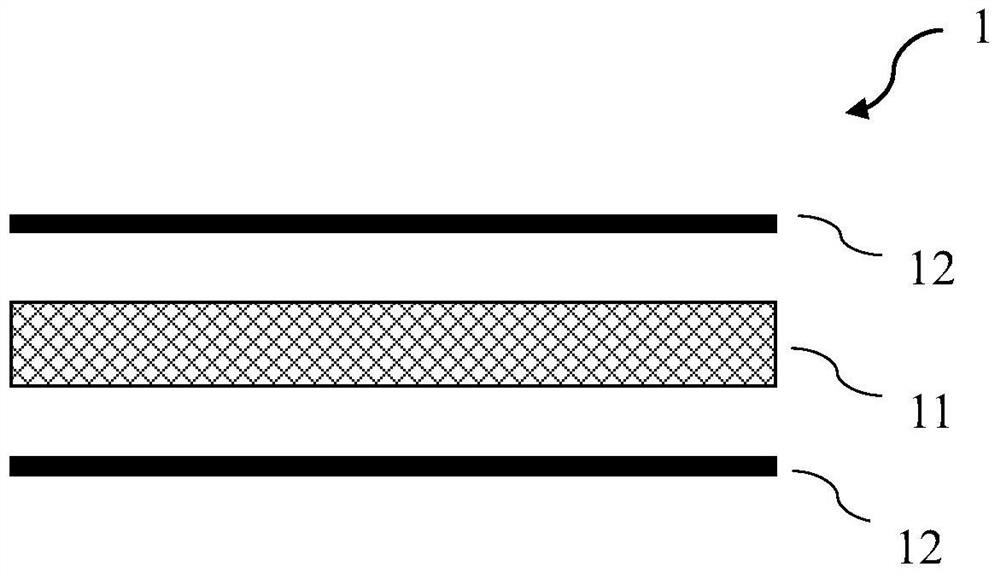

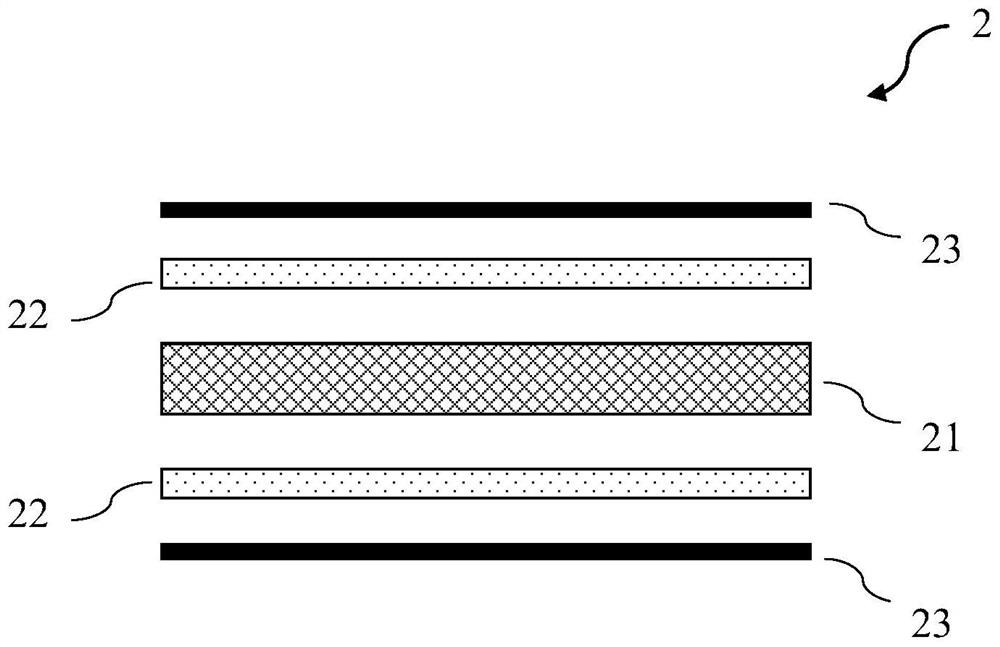

Metal foil laminated board, printed circuit board and manufacturing method of metal foil laminated board

A metal foil, laminated board technology, applied in printed circuits, printed circuits, printed circuit components, etc., can solve problems such as easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Get PTFE dispersion liquid (PTFE solid content 60% by weight) 666.67 grams and SiO 2 600 grams of fillers were evenly mixed to form the first glue (that is, in the solid content of the glue, the fillers accounted for 60% by weight). The first glue is further stirred to form a dough-like (dough-like), and extruded to obtain a sheet-like material, which is dried to remove the moisture and surfactant originally present in the PTFE dispersion, and then heated at a high temperature of 360°C Baking was performed to obtain a PTFE dielectric layer (first dielectric layer) not containing reinforcing cloth.

[0084] In addition, get 1333.33 grams of PTFE dispersion liquid (PTFE solid content 60% by weight) and SiO 2 200 grams of fillers were evenly mixed to form the second glue (that is, in the solid content of the glue, the fillers accounted for 20% by weight). The 1080 type E-glass fiber cloth (thickness 64 microns) was impregnated with the second glue, impregnated twice to a...

Embodiment 2

[0087] Get PTFE dispersion liquid (PTFE solid content 60% by weight) 666.67 grams and SiO 2 600 grams of fillers were evenly mixed to form the first glue (that is, in the solid content of the glue, the fillers accounted for 60% by weight). The first glue is further stirred to form a dough-like (dough-like), and extruded to obtain a sheet-like material, which is dried to remove the moisture and surfactant originally present in the PTFE dispersion, and then heated at a high temperature of 360°C Baking was performed to obtain a PTFE dielectric layer (first dielectric layer) not containing reinforcing cloth.

[0088] In addition, get 1333.33 grams of PTFE dispersion liquid (PTFE solid content 60% by weight) and SiO 2 200 grams of fillers were evenly mixed to form the second glue (that is, in the solid content of the glue, the fillers accounted for 20% by weight). The 1067-type E-glass fiber cloth (thickness 35 microns) is impregnated with the second glue, and impregnated twice t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com