Vehicle fan heater motor

A heater and motor technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of poor sealing, low room temperature, cumbersome operation, etc., and achieve the effect of accelerating the rate of air temperature rise and air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

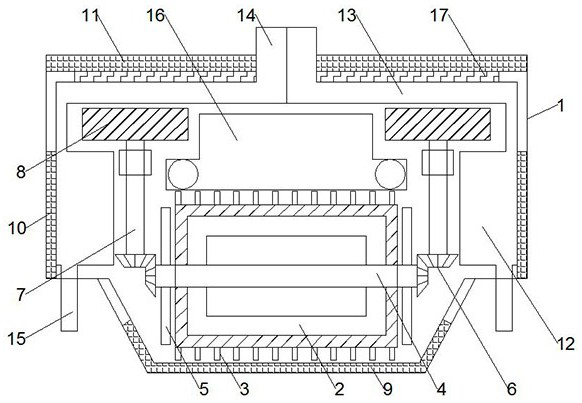

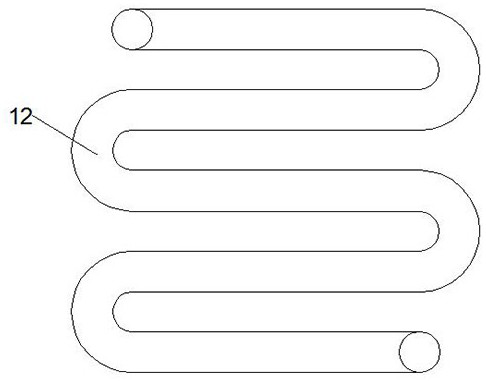

Embodiment 1

[0021] see figure 1 , in an embodiment of the present invention, a heater motor for a vehicle includes an outer cover 1, a horizontal motor 2 is arranged inside the outer cover 1, a rotating shaft-4 is arranged inside the motor 2, and the outer side of the motor 2 is along the direction of the rotating shaft-4. The axial direction is provided with cooling fins 3, and the left and right ends of the rotating shaft-4 are provided with fan-blades-5. The fan-blades-5 are composed of a disc-shaped whole, and several slits are arranged symmetrically in the center of the middle. Rotate along the direction of rotating shaft one 4, the air on both sides of fan blade one 5 is formed into an air flow, and the air flow is accelerated. The bevel gear set 6 is connected with the rotating shaft 2 7, and the upper end of the rotating shaft 7 7 is connected with the fan blade 2 8, and the rotating shaft 2 7 is rotatably connected in the outer cover 1, and the lower side of the motor 2 is provid...

Embodiment 2

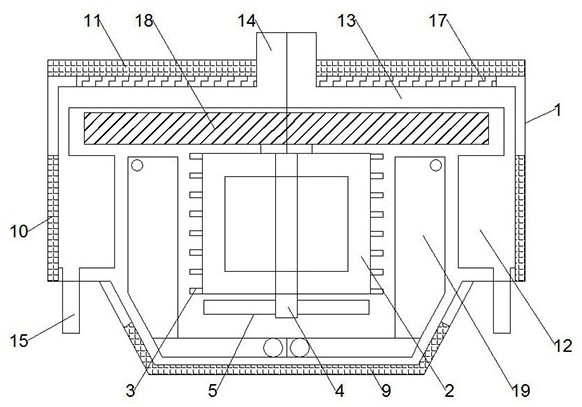

[0023] see figure 2 The difference between the present embodiment and the first embodiment is that: the outer cover 1 is provided with a vertical motor 2, the motor 2 is provided with a rotating shaft 4, and the outer side of the motor 2 is provided with a cooling fin 3 along the axial direction of the rotating shaft 4. , the lower end of the rotating shaft one 4 is provided with a fan blade one 5, the upper end of the rotating shaft one 4 is connected with a fan blade three 18, the left and right sides and the lower side of the motor 2 are provided with a condensation pipe two 19, and the condensation pipe Two 19 are connected to the refrigeration system in the car, and the air flow is driven by the fan blade three 18, and the heat in the hot water pipe is discharged into the car through the ventilation mesh three 11 by heat transfer.

[0024] The working principle of the present invention is: when in use, the hot water of the engine is transported through the thermal serpen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com