Cyclone generator

A technology of swirl generator and discharge hole, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc. It can solve the problem of insufficient displacement of the lower casing string, limited ability to replace drilling fluid, and Concave-convex and uneven problems, to achieve the effect of improving mechanical efficiency, facilitating large-scale promotion and use, and high initial speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

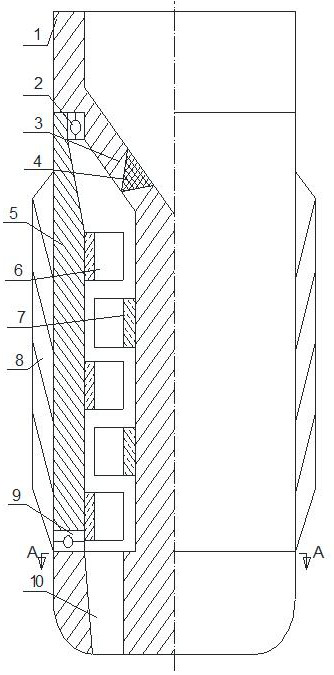

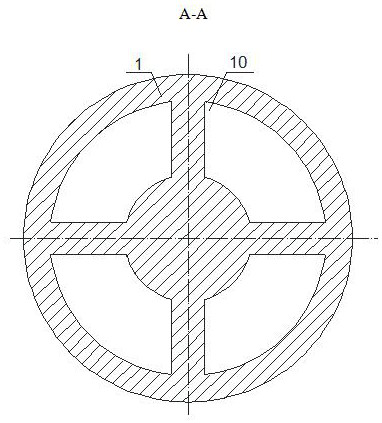

[0030] A swirl generator, comprising a central shaft 1, a one-way valve 4, an outer casing 5, a rotor 6, a stator 7, and a guide body 8; The through hole 3 is provided with a discharge hole 10 at the lower part of the central axis 1 . The outer casing 5 is wrapped on the annular groove of the central shaft 1, and forms a rotational fit with the central shaft 1. An annular driving chamber is formed between the outer casing 5 and the central shaft 1, and the upper and lower sides of the annular driving chamber respectively communicate with the bypass The hole 3 and the discharge hole 10 are connected. here combined with figure 1 , The center shaft 1 with the annular groove part of the axis is a closed structure to ensure that the fluid can only flow along the bypass hole 3, the annular drive chamber to the discharge hole 10. The one-way valve 4 is arranged in the bypass hole to prevent the fluid from flowing backward. The rotor 6 and the stator 7 are arranged between the oute...

Embodiment 2

[0032] On the basis of embodiment 1, further include:

[0033] A bearing A2 is mounted on the upper part of the outer casing 5 and the central shaft 1 , and a bearing B9 is installed on the lower part of the outer casing 5 and the central shaft 1 .

[0034] The bearing A2 is mounted on the radial junction of the outer casing 5 and the central shaft 1 , and the bearing B9 is installed on the axial junction of the outer casing 5 and the central shaft 1 .

[0035] Bearing A is a rolling bearing, and bearing B is a thrust bearing.

Embodiment 3

[0037] On the basis of embodiment 1 or 2, further include:

[0038] The upper section of the outer annular groove of the central shaft 1 is a tapered or arc-shaped surface, and the bypass hole 3 is arranged on the tapered or arc-shaped surface. This design better solves the force of the fluid on the rotor.

[0039] The bottom of the outer annular groove of the central shaft 1 is a plane, and the discharge hole 10 is arranged axially along the annular drive chamber between the outer shell 5 and the central shaft 1 to increase the smoothness of the flow channel.

[0040] There are multiple bypass holes 3, which are determined according to factors such as hole diameter, fluid flow rate, casing pipe diameter, pressure, etc., and are uniformly distributed.

[0041] There are multiple discharge holes 10, the number and diameter of which are specifically set according to requirements, and are uniformly distributed; or the discharge holes 10 directly adopt an integral annular structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com