A floor heating and heat radiation structure for enhancing heat radiation and its installation method

A technology of heat dissipation structure and heat radiation, which is applied in the field of civil engineering, can solve the problems of inability to utilize heat of floor heating pipes, heat waste, etc., and achieve the effects of solving heat dissipation waste of floor heating, enhancing structural stability and simple construction method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

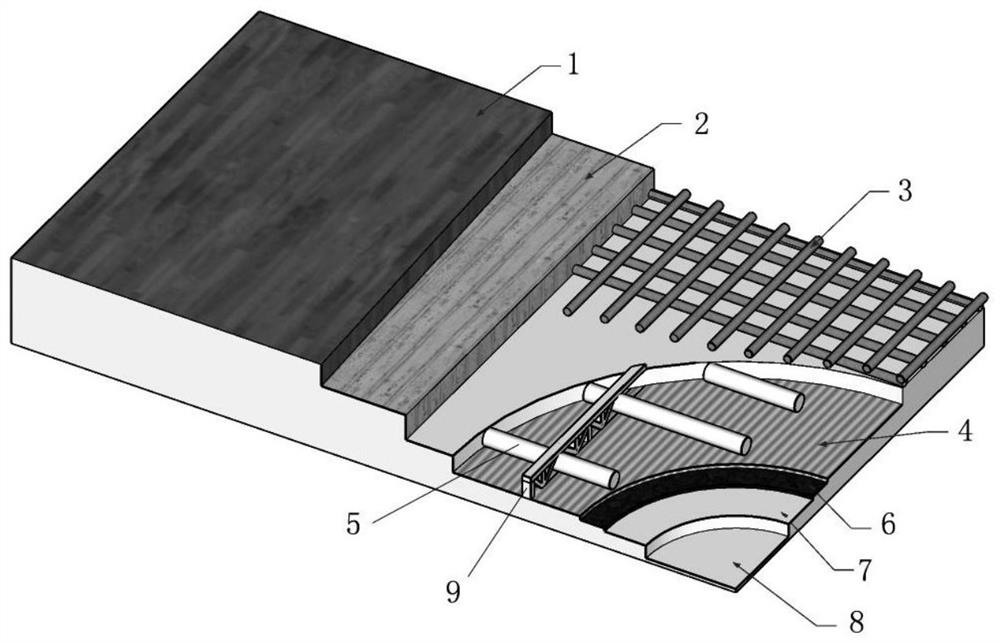

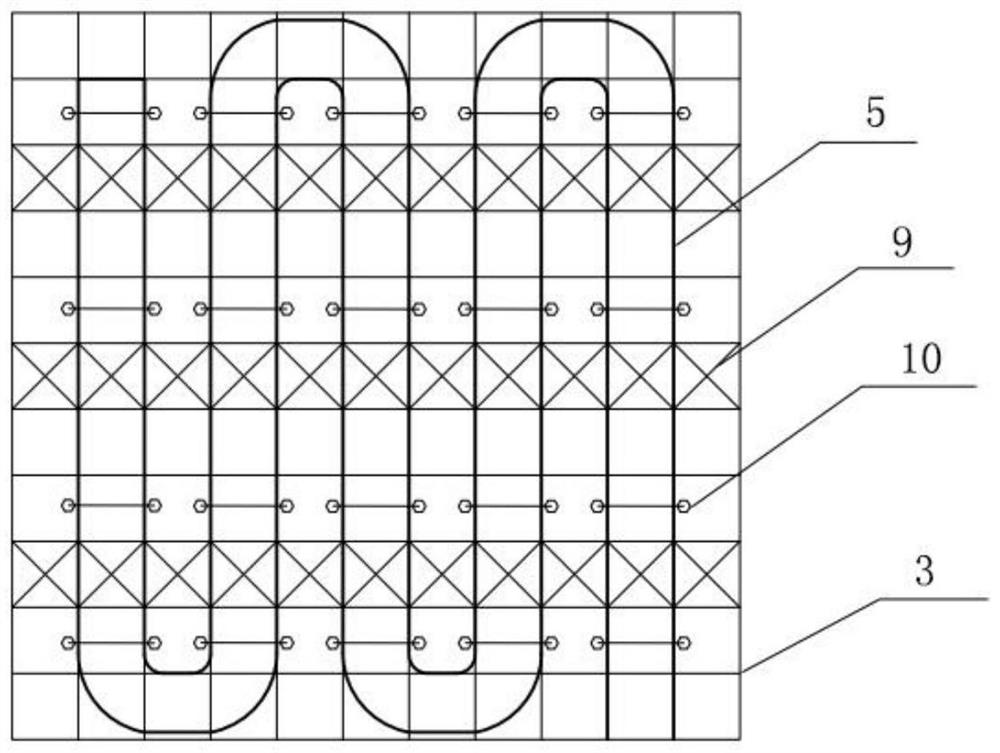

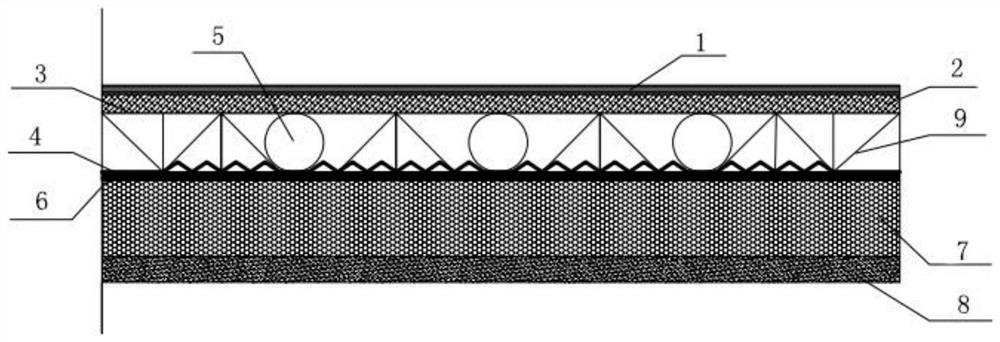

[0036] Such as Figure 1-4 As shown, the present invention provides a floor heating and heat dissipation structure that enhances heat radiation, which sequentially includes a floor 1, a heat transfer layer 2, a steel mesh 3, a floor heating pipe 4, a reflection layer 5, a waterproof layer 6 and a heat insulation layer from top to bottom 7. The reflective layer 5 is made of uneven tinfoil; the installation space is formed by setting a steel wire mesh frame between the floor heating pipe 4 and the waterproof layer 6, and the uneven tinfoil is set in the installation space , the installation space formed by the wire mesh frame can ensure that the tinfoil will not be flattened during the installation process; the floor heating pipe 4 adopts a serpentine laying method, and is fixedly installed on the steel bar through a truss 9 Between the net 3 and the reflective layer 5, the serpentine laying method will not cause some pipes to be bent or even dead folded, thereby affecting the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com