Semiconductor structure and forming method thereof

A semiconductor and gate electrode technology, applied in the field of semiconductor structure and its formation, can solve the problems of device size uniformity and performance uniformity to be improved, and achieve the effect of small etching area and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]It is understood that the electrical properties of the semiconductor device remain to be improved. The formation of a semiconductor structure is now analyzed by the cause of electrical performance still needs to be improved.

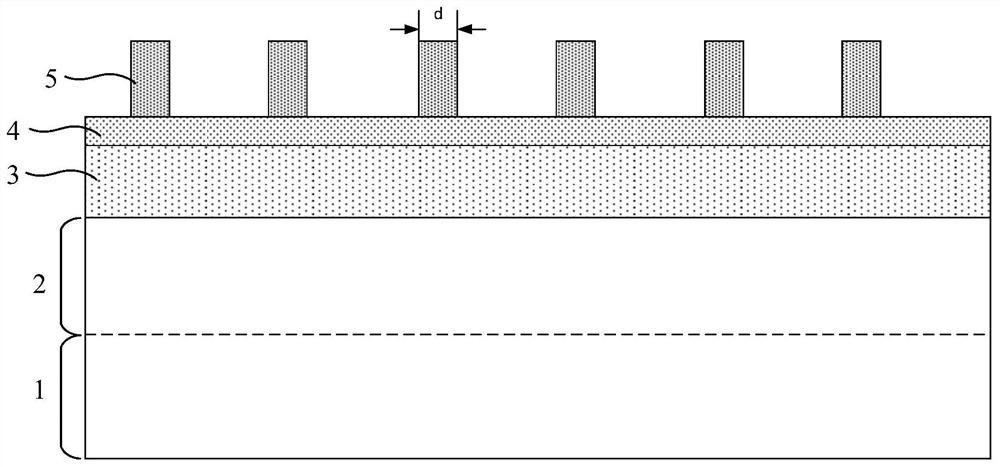

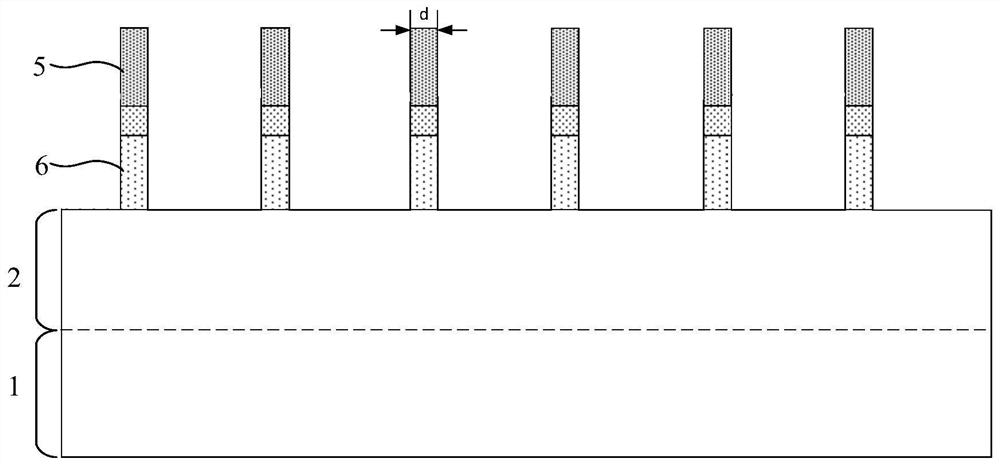

[0050] reference Figure 1 to 2 The structural diagram of each step corresponding to the formation method of a semiconductor structure is shown.

[0051] Such as figure 1 As shown, a substrate is provided, the substrate comprising a substrate 1 and a fin 2 that protrudes from the substrate 1, and a gate electrode material layer 3, a hard mask material layer 4, and a mask layer are sequentially formed on the substrate. The mask layer includes a plurality of discrete side wall blocks 5 formed from the Self-Aligned Quadrule Patterning, SAQP process, which are characteristic size D.

[0052] Then figure 2 As shown in the mask, the mask layer is sealed, and the hard mask material layer and the gate electrode material layer are sequentially etched, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com