Neodymium iron boron magnetic powder block automatic crushing device and method

A crushing device, NdFeB technology, applied in chemical instruments and methods, solid separation, filtration, etc., can solve the problems of low screening efficiency and crushing efficiency, and achieve the effect of improving energy utilization and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

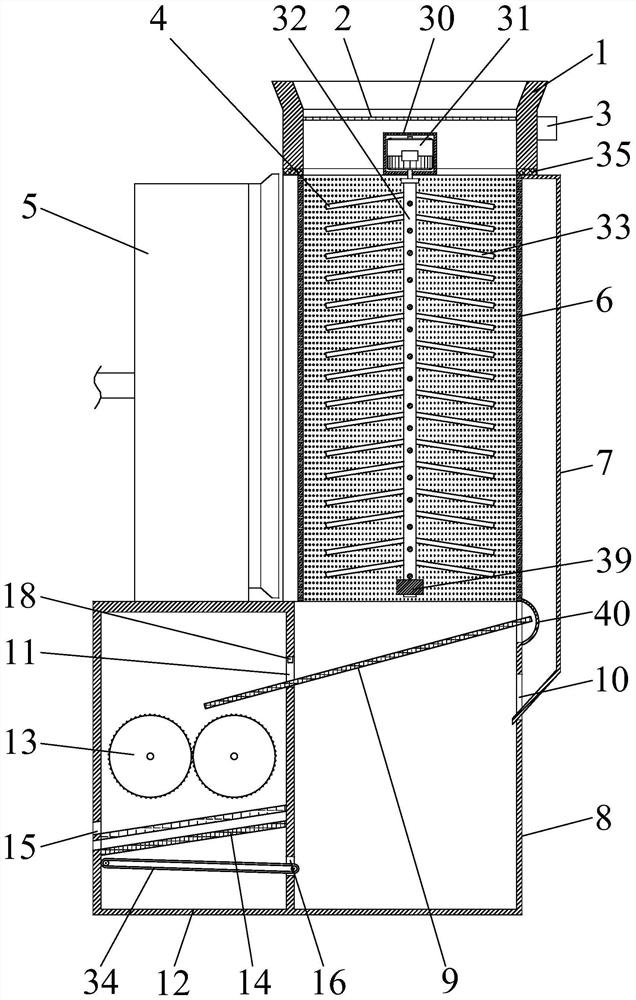

[0072]Seefigure 1 The present invention provides an automatic pulverizing apparatus of a neodymium iron boron magnet powder for sieving the neodymium iron boron magnet block formed by the NdFeB magnetic powder, thereby forming a magnetic powder having the same particle size range. Among them, the neodymium iron boron magnet block automatic pulverization device includes a vibration dispersing mechanism, a strand mechanism, a blast recovery mechanism, a screening collecting mechanism, a pulverizing mechanism, a detection mechanism, and a controller.

[0073]The vibration dispersing mechanism includes a dispersing cartridge 1, a screen one 2, and a vibration source 3. Screen One 2 is mounted in the dispersion cartridge 1 and is used to sieve the external input NdFe boron magnet block. The vibrating source 3 is mounted on the dispelling cartridge 1 and is used for vibrating screens 2. In the present embodiment, the dispersing cartridge 1 is a cylinder, both ends thereof. The dispelling car...

Embodiment 2

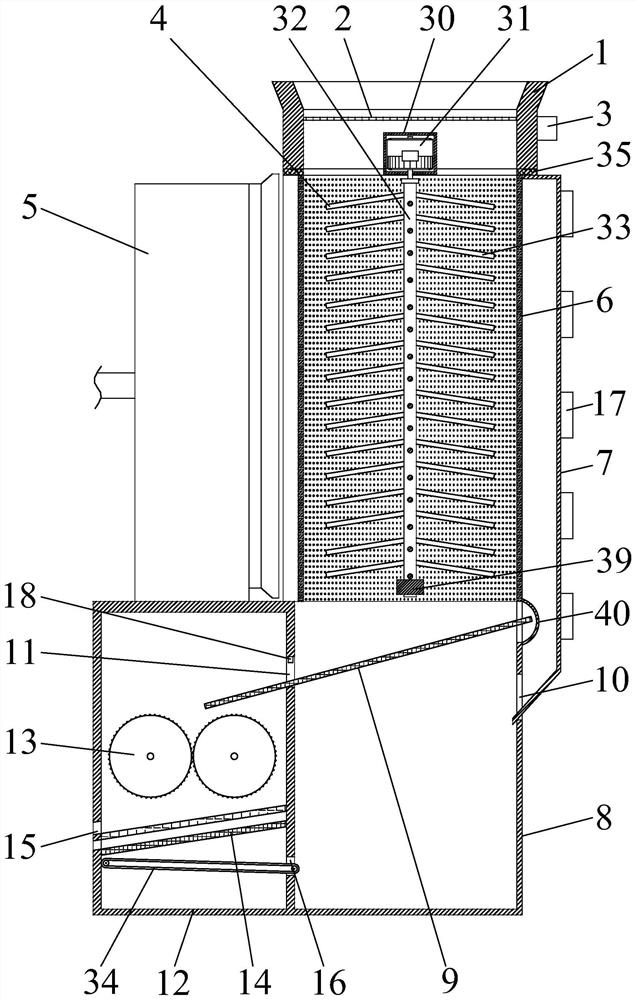

[0085]Seefigure 2 In this embodiment, the present embodiment provides an automatic pulverizing apparatus of a neodymium iron boron, which increases the electromagnet 17 on the basis of Example 1. The amount of electromagnet 17 is multiple, and the electromagnet 17 belongs to the blast recovery mechanism. The electromagnet 17 is mounted on the outer wall of the recovery housing 7. The controller is also used to activate the electromagnet 17 once every other preset time, so that the magnetine generated by the electromagnet 17 is adsorbed on the magnetic powder of the recovery housing 7 on the inner wall of the recovery housing 7, and the working time of the electromagnet 17 Turn off the electromagnet 17 at 2 times in a preset time.

[0086]Therefore, the NdFrobolam magnetic powder block automatic pulverization device provided in this example is capable of generating a magnetic field effect on the magnetic powder in the recovery housing 7, so that the magnetic powder is adsorbed on the in...

Embodiment 3

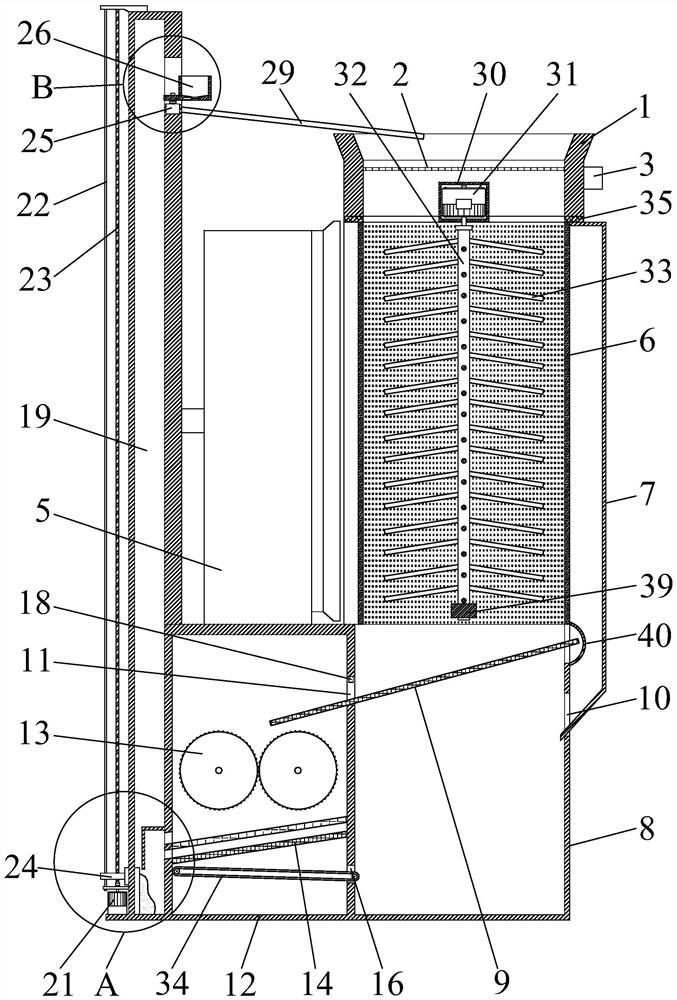

[0088]SeeFigure 3-7In this embodiment, a non-ferrous barrin pulverizing apparatus is provided, and the conveying mechanism is added based on the first embodiment. The conveying mechanism is used to deliver the NdFe boron magnet block rolled out from the outlet one 15 to the screen one 2. Among them, the controller is driven for each of the preset time three to transport the transport mechanism to a neodymium iron boron.

[0089]The conveying mechanism in this embodiment includes a lifting tub 19, a lifting assembly, an electromagnetic absorbing block 20, a rotating assembly, and a feed assembly. The lift bucket is located on one side of the pulverized housing 12 and receives a neodymium iron boron magnetic powder that rolls out from the outlet one 15. The discharge port 36 is opened on the side wall of the lifting tub 19, and the height of the discharge port 36 is higher than the height of the dispersing cartridge 1. The lifting assembly is mounted on the lifting tub 19 and is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com