Parcel supply system, cross belt sorting system and parcel supply method

A technology for supplying bags and sorting machines, which is applied in sorting, transportation and packaging, conveyor control devices, etc., can solve the problems of high labor intensity, large influence of human factors, and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0099] This embodiment discloses a cross-belt sorting system, as attached Figure 20 As shown, it includes the bag supply system of the above embodiment, the output end of the bag supply platform 1 of the bag supply system is connected to the outside of the cross belt trolley loop 6, of course, it can also be connected to the inside, or the cross belt trolley loop 6 Both sides of 6 are connected to the bag supply platform 1 of the bag supply system at the same time. The specific structure of the cross belt trolley loop 6 may be the structure disclosed in the application numbers 201810494195.8, 201821732552.1, etc., which will not be repeated here.

[0100] At least one side of the cross-belt trolley loop 6 is provided with a sorting grid 7 , and the sorting grid 7 is arranged on both sides of the cross-belt trolley loop 6 . Below take a section of the cross belt trolley loop line 6 as an example to illustrate, it is arranged on a platform 8, as attached Figure 21 - attached...

Embodiment 3

[0117] The present embodiment discloses a kind of sorting method, comprises the steps:

[0118] S1, placing a large number of items into the single-piece separating conveyor 5 manually or through automated equipment (unpacking robot).

[0119] S2, the single-piece separation conveyor 5 transports the items one by one to the six-sided code-scanning conveying line 4 .

[0120] S3, the six-sided code-scanning conveying line 4 obtains the routing information (sorting slot) and weight of the articles passing through it, and conveys the articles to the deflection wheel sorter 3 .

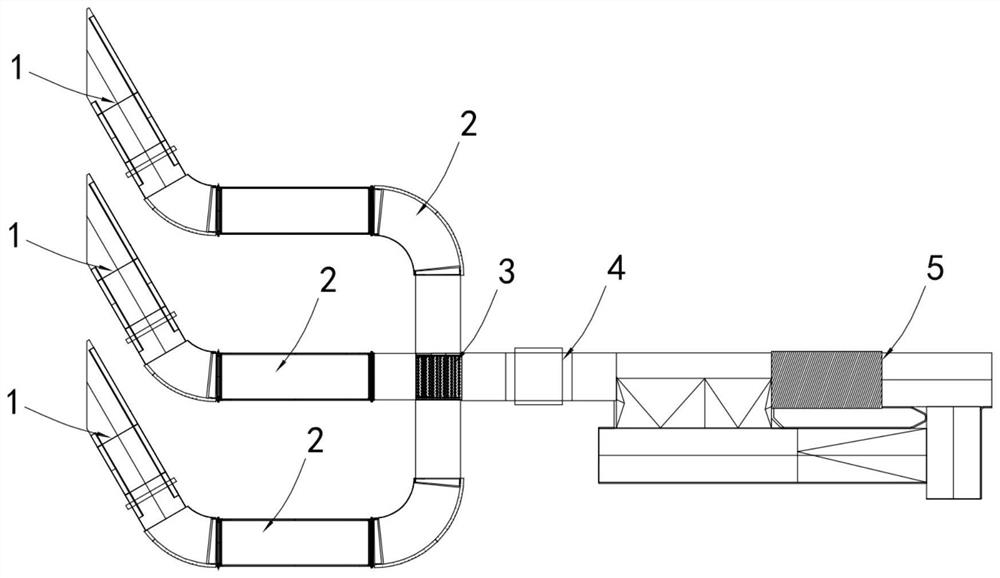

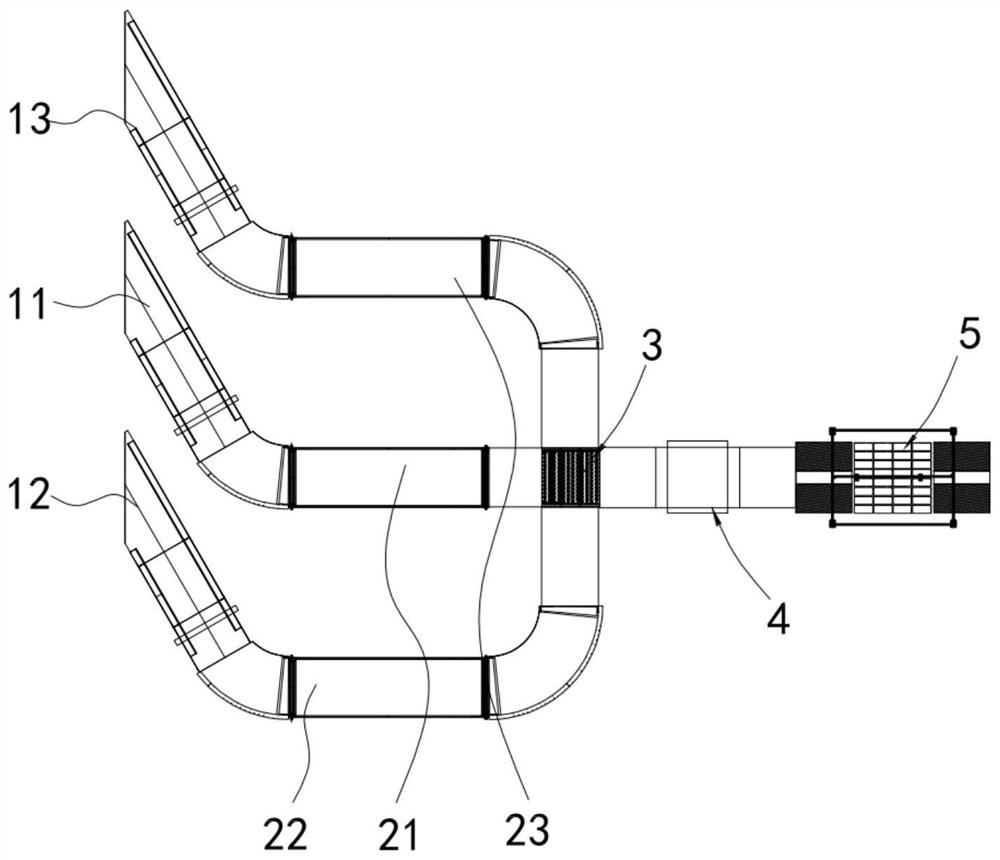

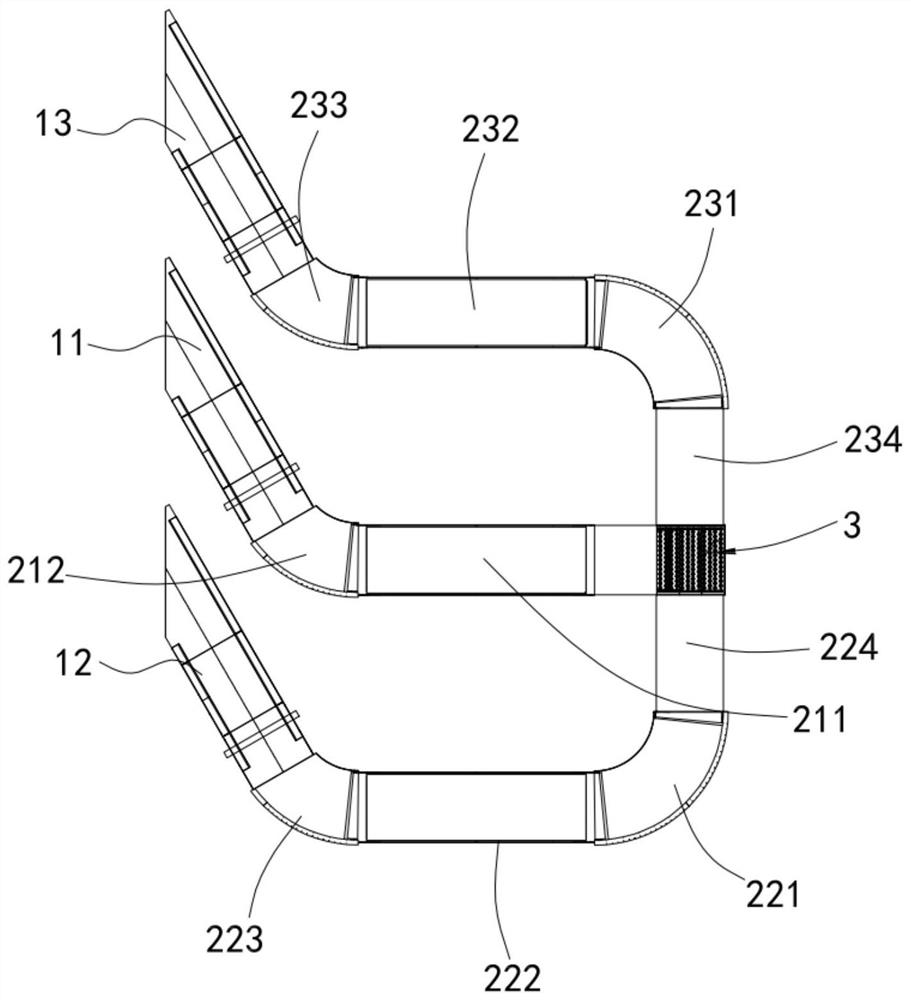

[0121] S4, the deflection wheel sorter 3 alternately transports the items to the three transfer conveyor lines 2, and the transfer conveyor lines 2 transport the items to the corresponding bag supply table 1.

[0122] S5, the bag supply platform 1 transports the items to the reserved trolley for transport.

[0123] S6, the items are sorted by the trolley into the corresponding sorting slots.

[0124] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com