Disinfection equipment for cleaning polyethylene raw material barrel

A technology for disinfection equipment and raw material barrels, which is applied in sanitary equipment for toilets, disinfection, lighting and heating equipment, etc. It can solve the problems of slow drying speed, prolonging the production cycle, and affecting the guarantee of output, so as to ensure negative pressure sealing Sex, the effect of guaranteeing the vacuum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

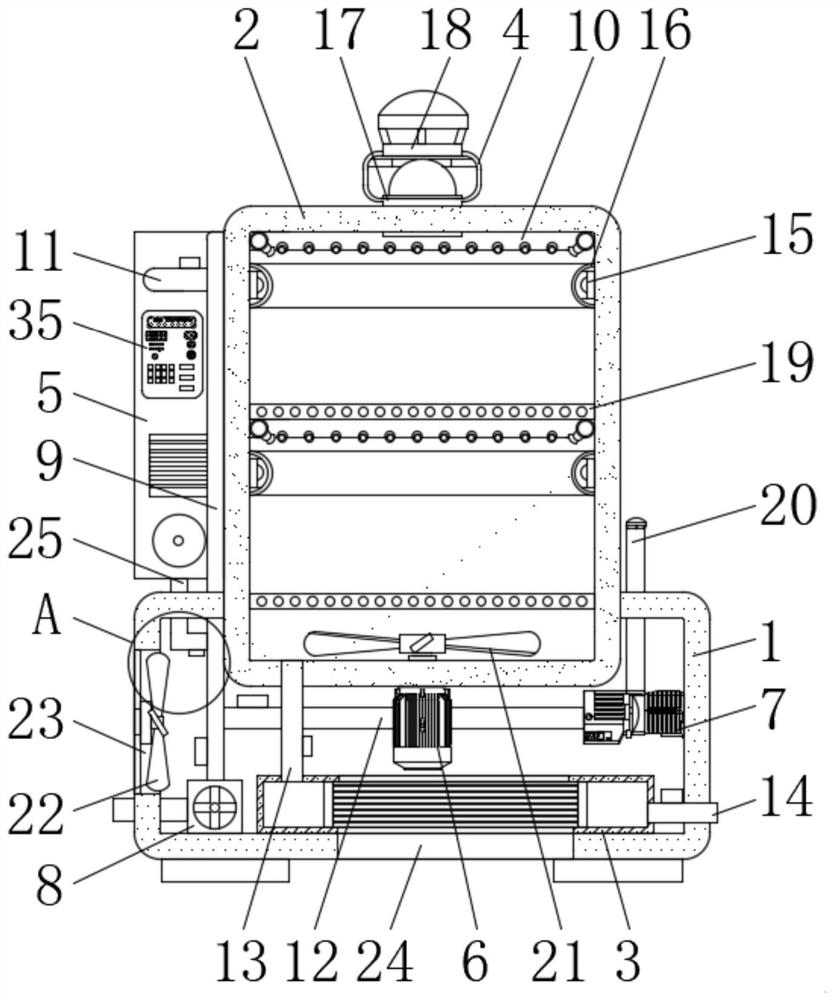

[0025] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

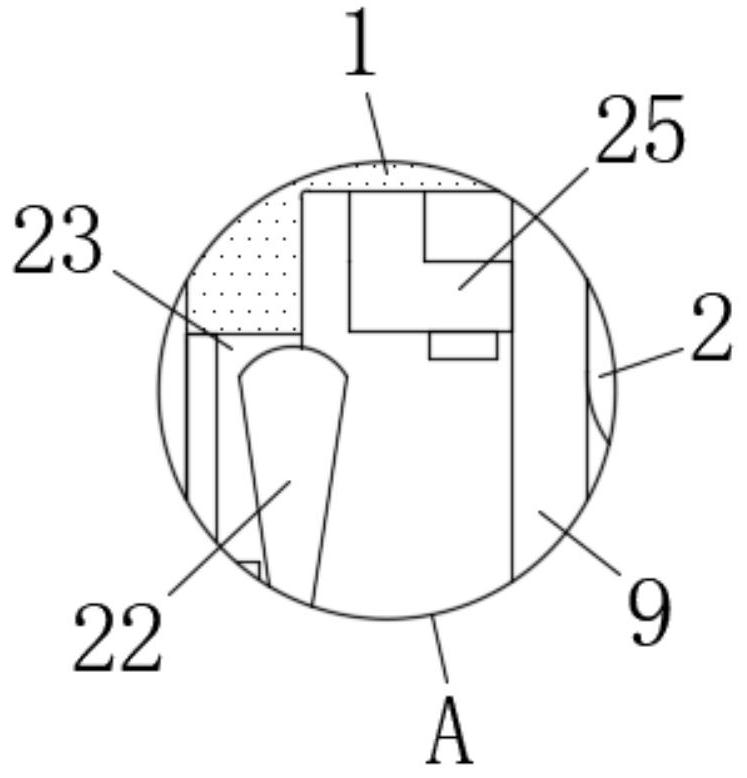

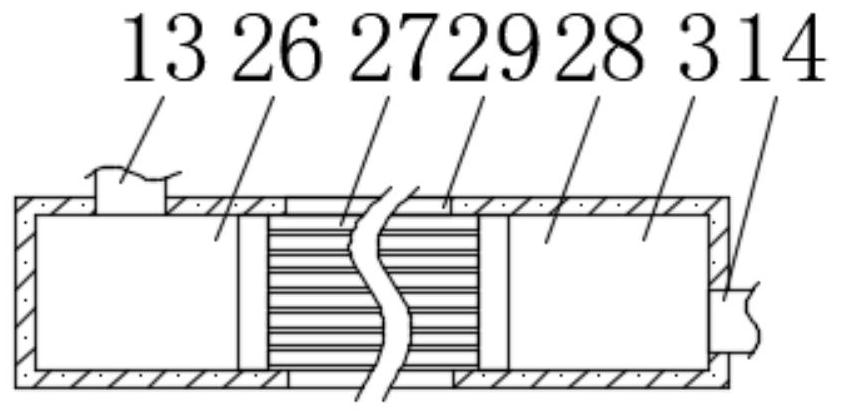

[0026] like Figure 1-5 As shown, the present invention provides a technical solution: a polyethylene raw material drum cleaning disinfection equipment, including a box 1, the upper surface of the inner wall of the box 1 is clamped with the surface of the cleaning box 2, and the lower surface of the inner wall of the box 1 It is fixedly connected with the lower surface of the cooling box 3, the left side of the cleaning box 2 is fixedly connected with the right side of the steam generator 5, the lower surface of the cleaning box 2 is fixedly connected with the upper surface of the motor 6, and the output shaft of the motor 6 is fixedly connected. Connected with rotating vane 21, the output shaft of motor 6 is clamped on the lower surface of the inner wall of cleaning box 2 through the closed water bearing, the right side of the inner wall of box bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com