Automatically-feeding shielding case die

A technology of automatic material feeding and shielding cover, which is applied in the direction of forming tools, manufacturing tools, feeding devices, etc. It can solve problems such as scratches, adhesion and difficulty of separation, and the influence of shielding cover production yield, so as to improve the yield rate and improve processing efficiency , to avoid the effect of scratching each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

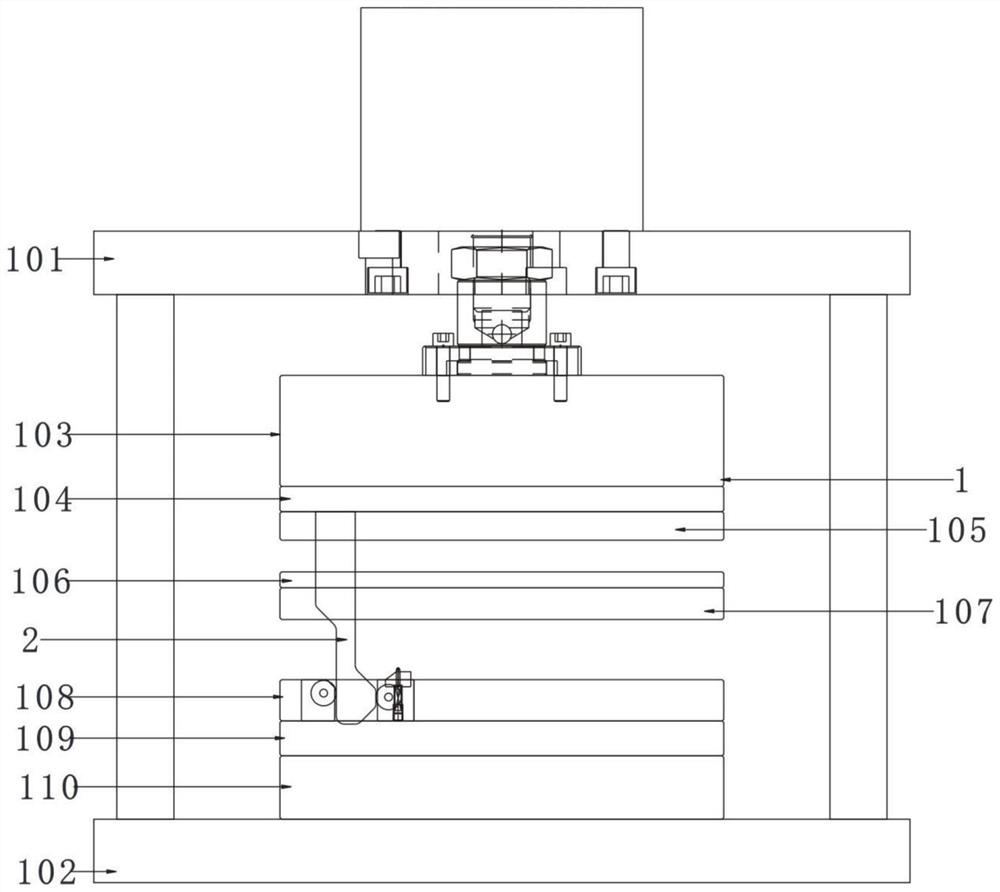

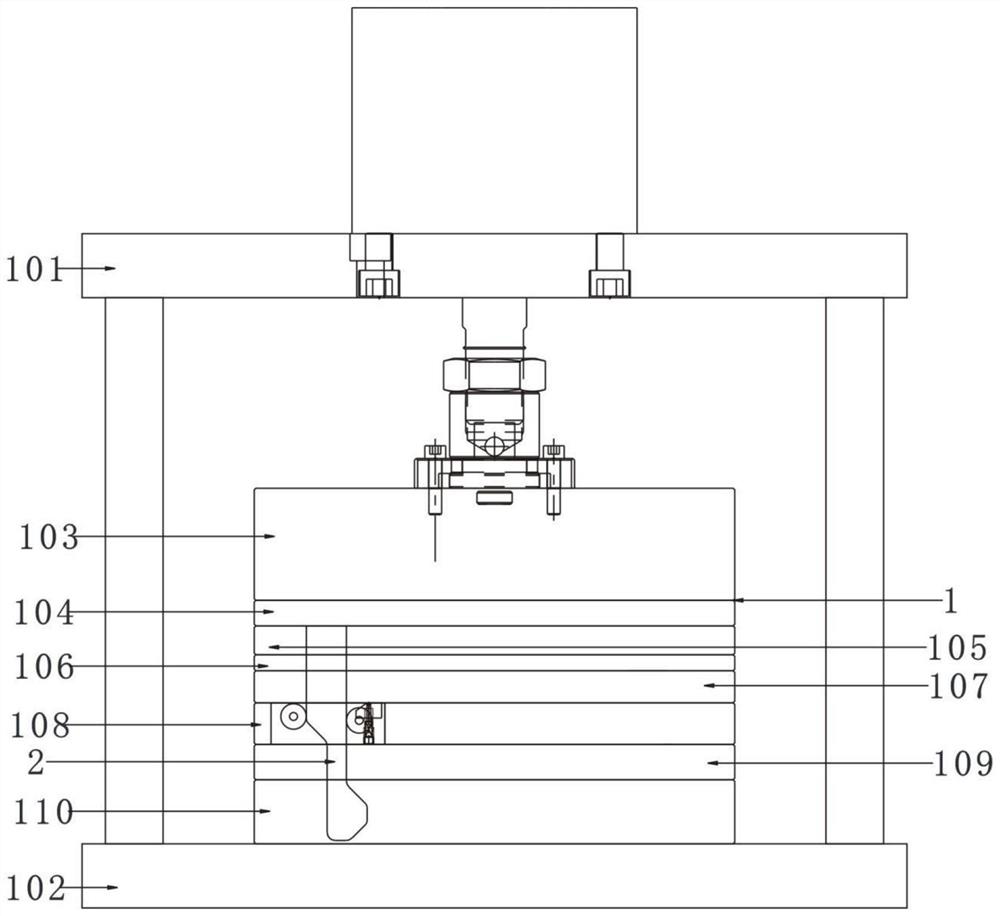

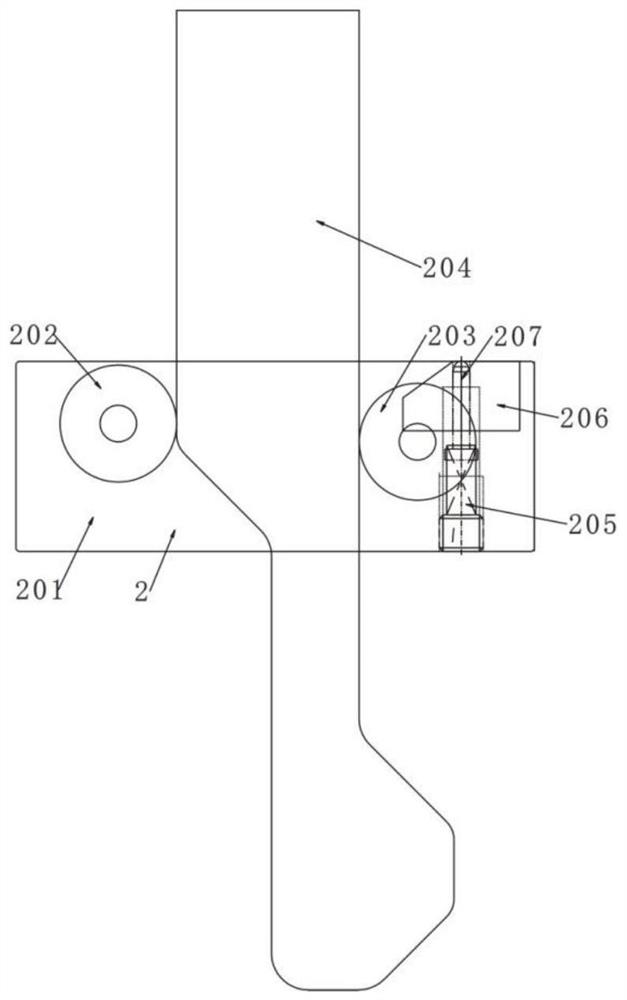

[0038] like figure 1 figure 2 image 3 As shown, an automatic feeding shielding mold, the mold includes an upper mold base, an upper backing plate, a fixed plate, a limit plate, a discharge plate, a concave plate, a lower backing plate, and a lower mold base, and the plates of the mold are stacked in sequence Installation, the inside of the mold is provided with an automatic feeding mechanism, and the automatic feeding mechanism includes a slider 201, a bearing, a movable block 206, a thimble 207, a spring 205, and a pull rod 204. Bearings are arranged on both sides of the pull rod 204 groove, a groove is arranged at the front end of the slider 201, a movable block 206 is arranged in the groove, a thimble hole is arranged on the movable block 206, a thimble 207 is arranged in the thimble hole, and a thimble 207 is provided at the bottom The spring 205, the upper end of the pull rod 204 are fixed on the upper backing plate 104 of the mold, the slider 201 is slidably installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com