Automatic welding equipment for plateau area railway station house beam columns

An automatic welding and railway station technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that welding equipment cannot adapt to plateau anoxic environment, low welding work efficiency, poor mobility, etc., and achieve improvement Mobility and flexibility, improve welding efficiency, and achieve the effect of height adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

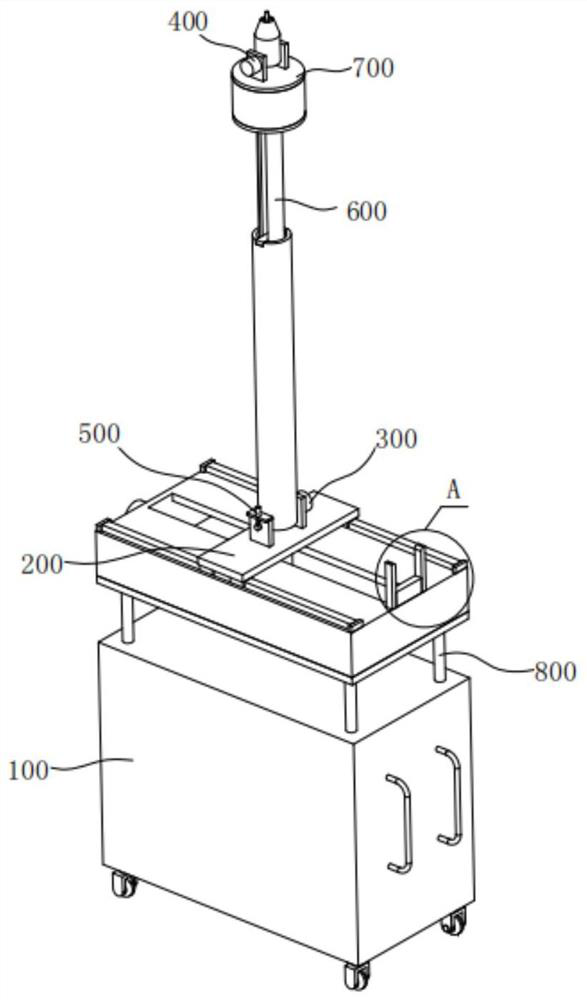

[0042] see figure 1 , the present invention provides a technical solution: an automatic welding equipment for beams and columns of railway station houses in plateau areas, including an installation assembly 100, a moving assembly 200, a rotating assembly 300 and a welding assembly 400, wherein the moving assembly 200 realizes the translation of the welding assembly 400 , the rotating assembly 300 implements the rotation of the welding assembly 400, and the welding assembly 400 implements the welding work.

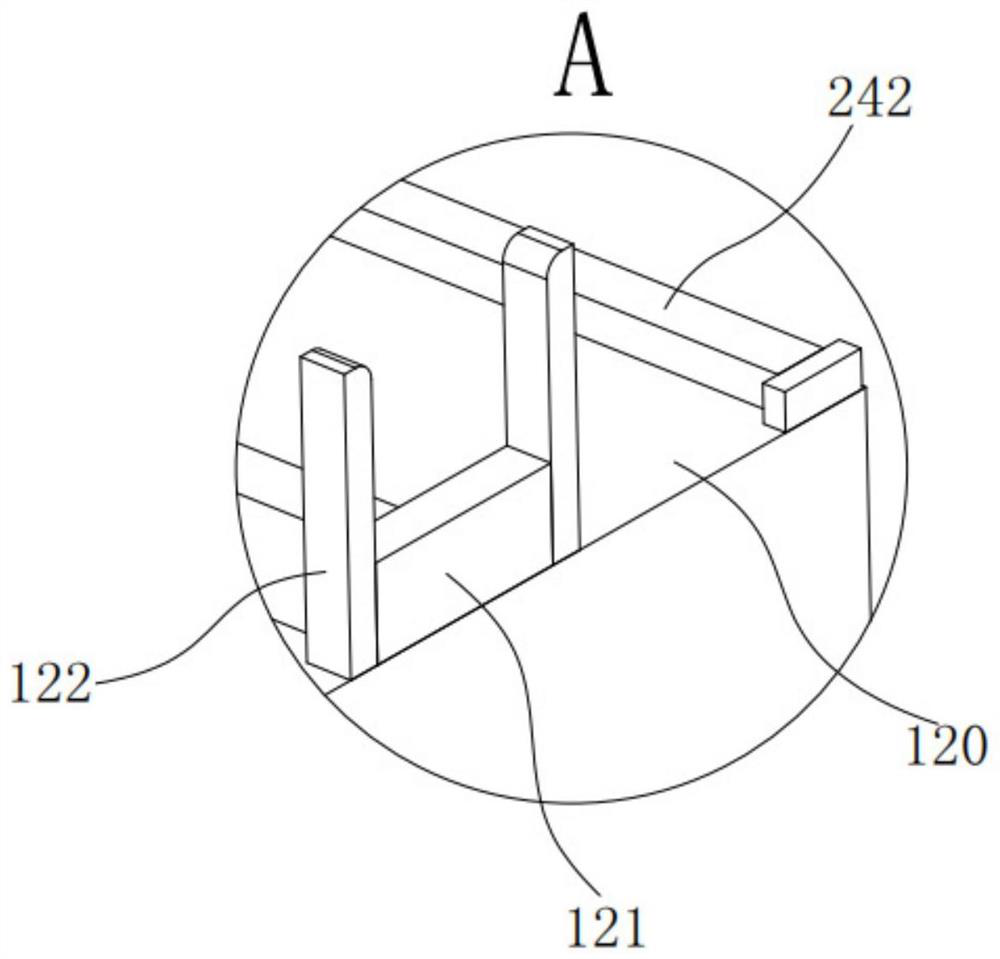

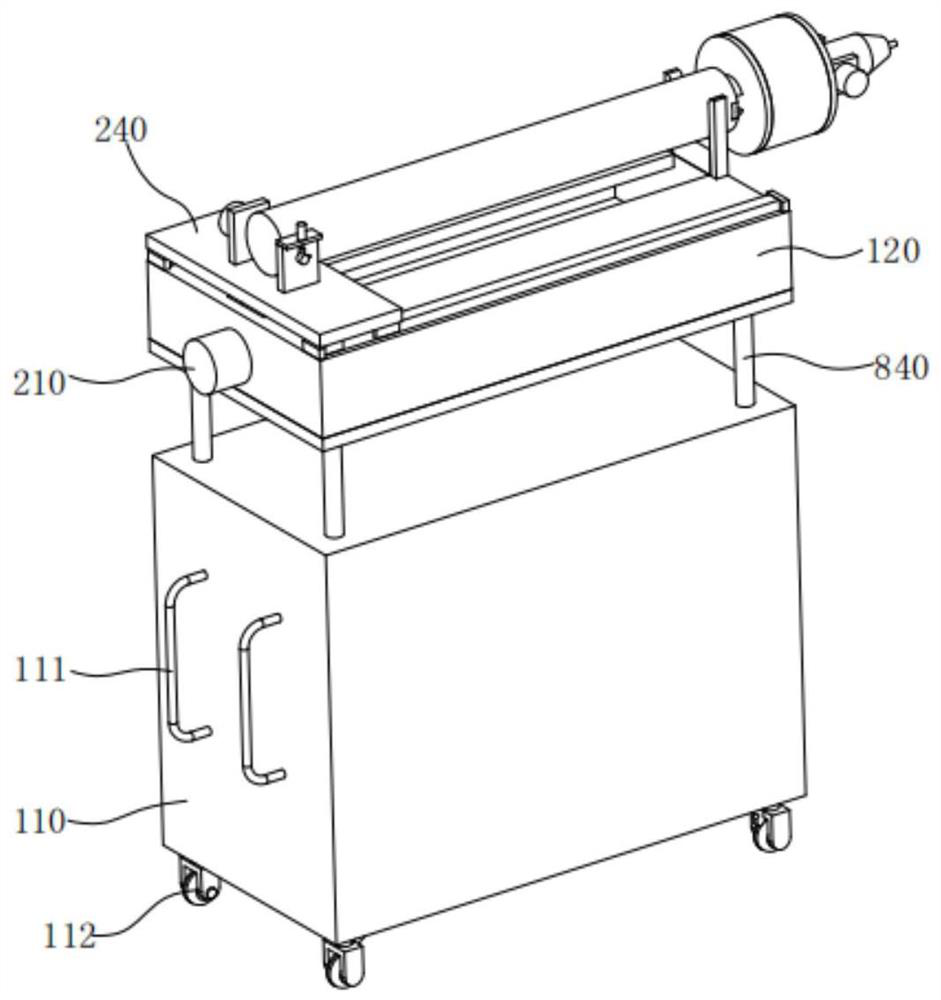

[0043] see figure 2 with image 3 , the installation assembly 100 includes a first installation box 110 and a second installation box 120 , and the second installation box 120 is disposed on the first installation box 110 . When setting it up specifically, the end of the second installation box 120 away from the first motor 210 is fixed with a support block 121 by welding, and both sides of the support block 121 are fixed with stopper blocks 122 by welding, and the insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com