Paper cutting method for papermaking

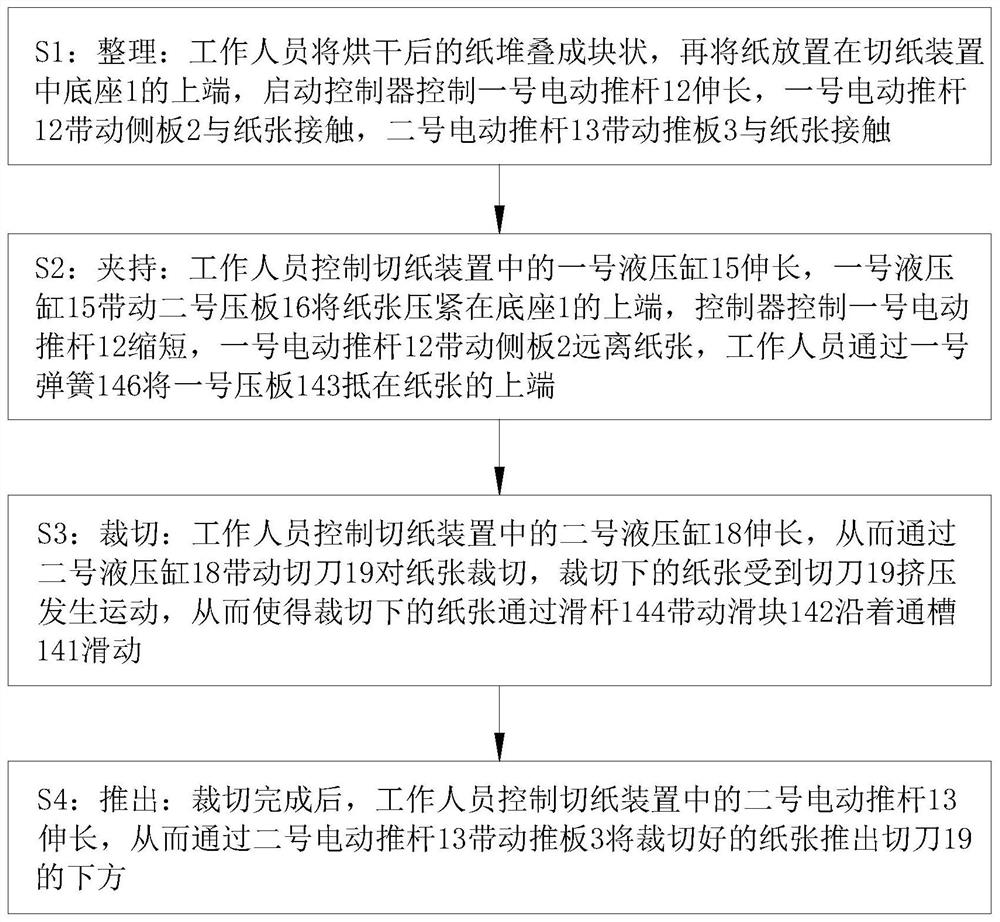

A technology of cutting paper and paper cutting device, which is applied in the direction of metal processing, etc., and can solve the problems of affecting the work efficiency of the staff, unstable cutting, paper disorder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

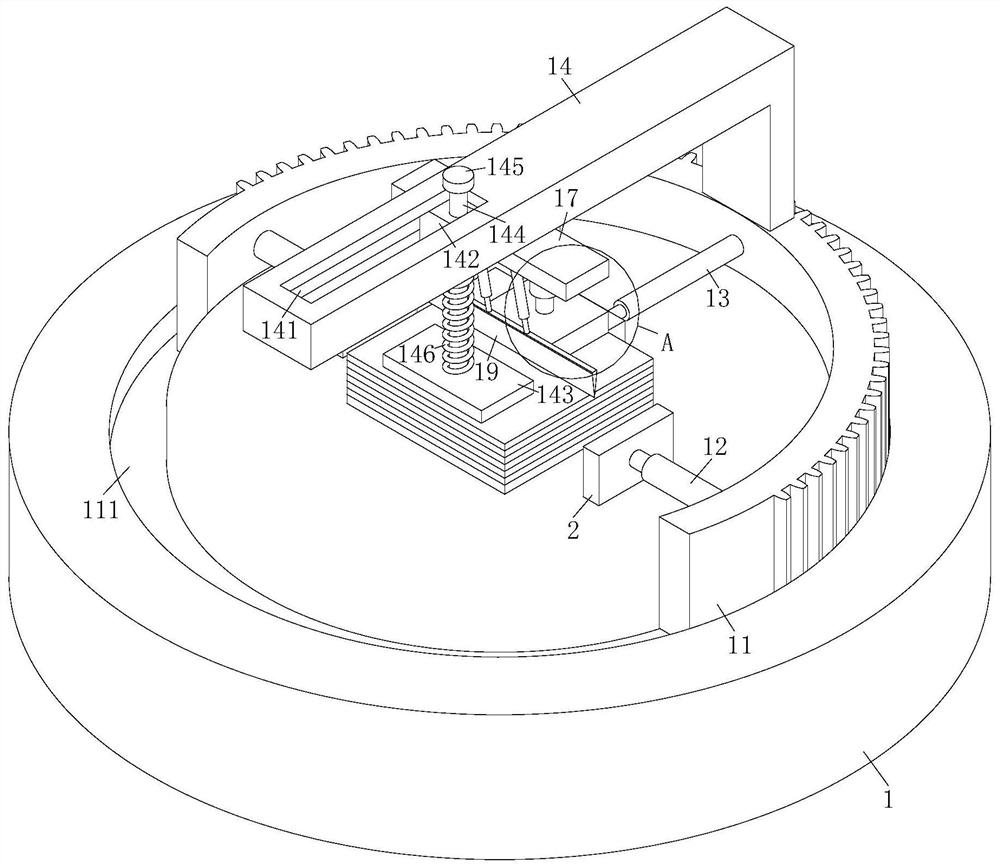

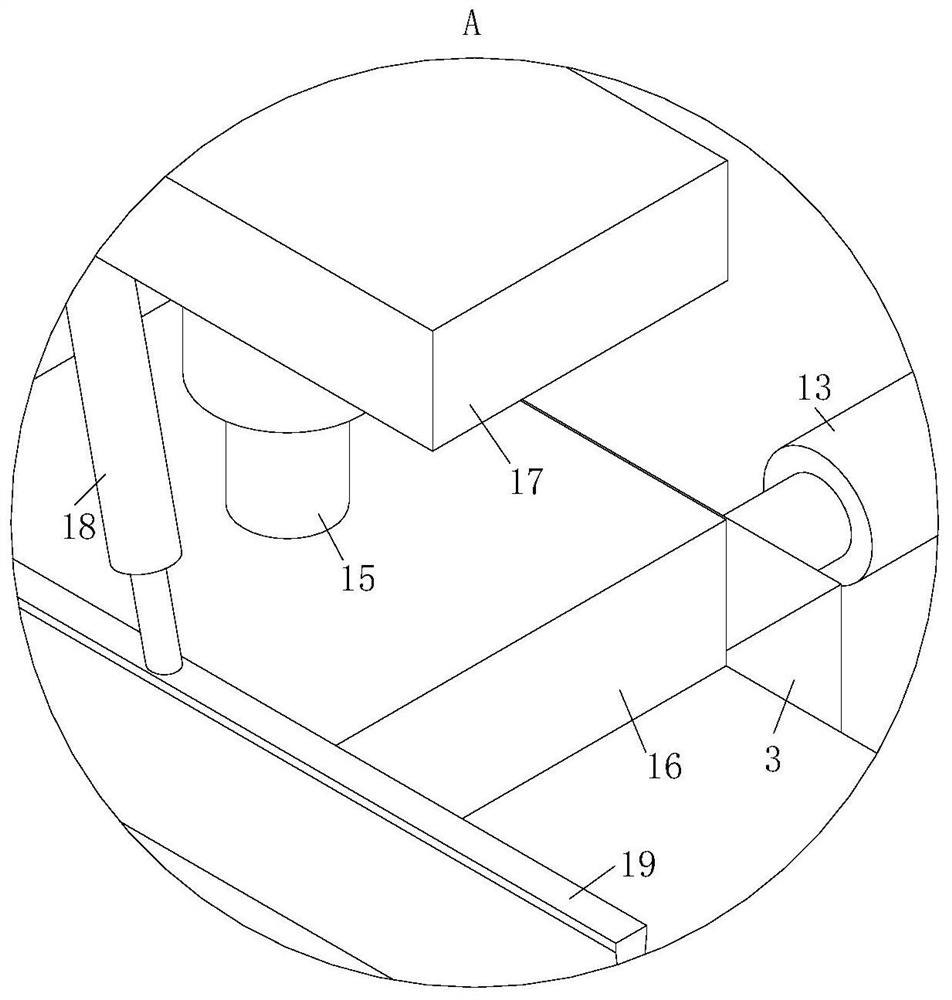

Examples

Embodiment approach

[0047] As an embodiment of the present invention, half of the surface of the airbag 21 is pasted with a layer of flexible film 22; the side of the flexible film 22 close to the paper is provided with a flexible hook 23; , so the edges of the paper are still stuck with fibers, so that the workers have to clean the edge fibers of the paper after cutting the paper; The plate 11 will drive the No. 1 electric push rod 12 to move, and the No. 1 electric push rod 12 will drive one of the side plates 2 to move, and one of the side plates 2 will drive the airbag 21 to move, because half of the surface of the airbag 21 is covered with a layer of flexible film 22 , so the airbag 21 drives the flexible membrane 22 to move, and at the same time, the No. 1 electric push rod 12 drives the flexible membrane 22 on the airbag 21 to contact the side of the paper. Because the flexible membrane 22 is provided with a flexible hook 23 on the side close to the paper, the flexible membrane 22 drives T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com