Tailor-welded pre-coated steel sheet and its hot-stamped components

A technology of hot stamping and laser tailor welding, which is used in layered products, welding equipment, metal layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

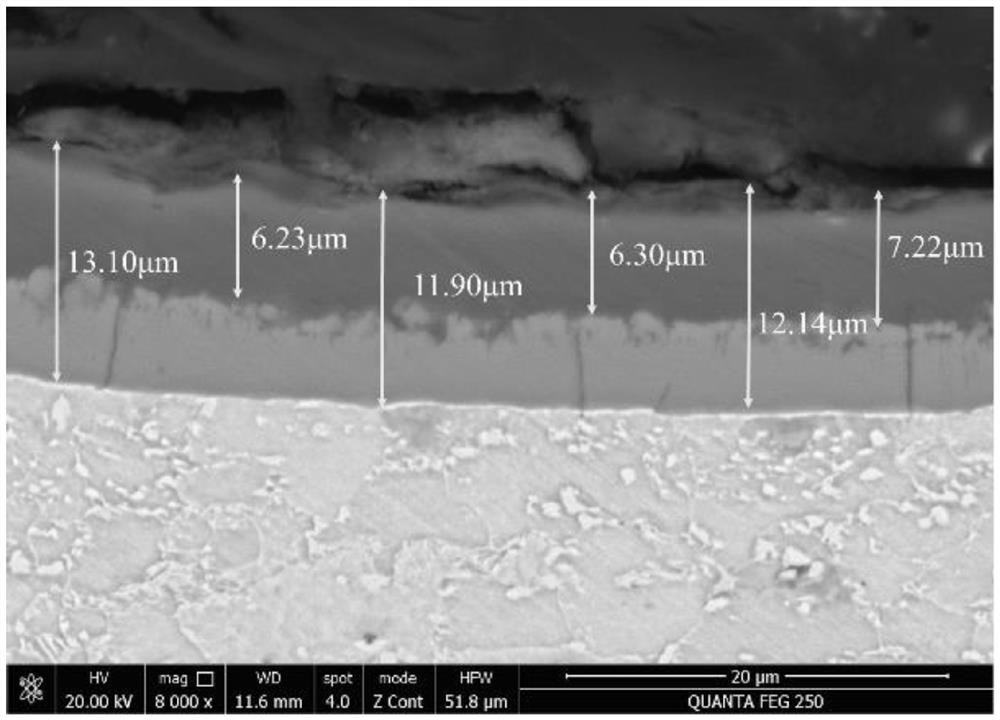

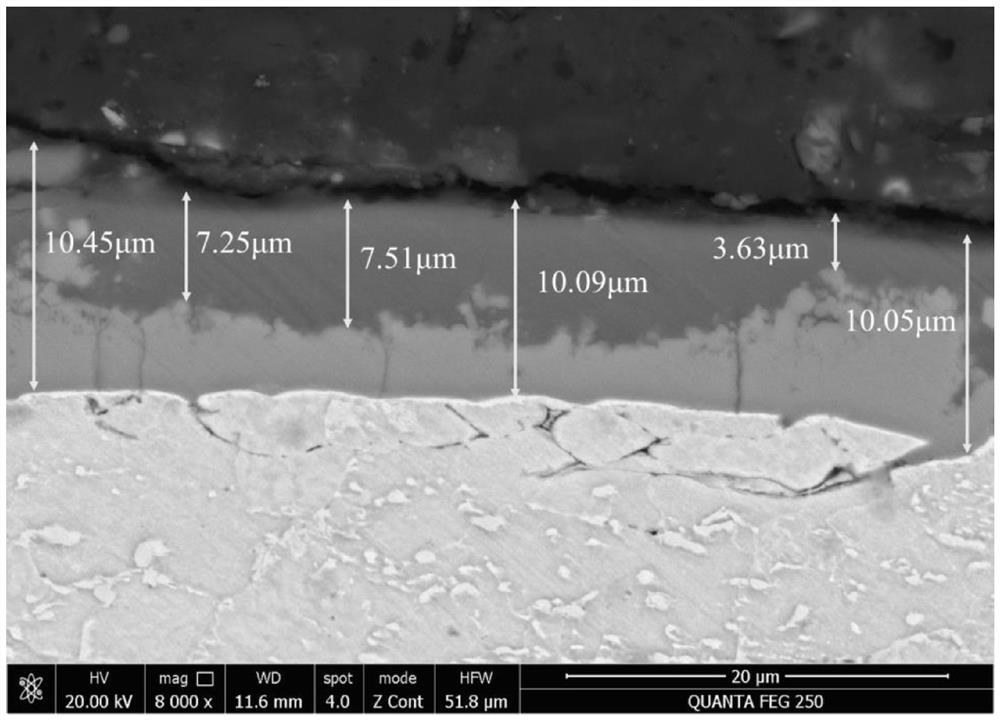

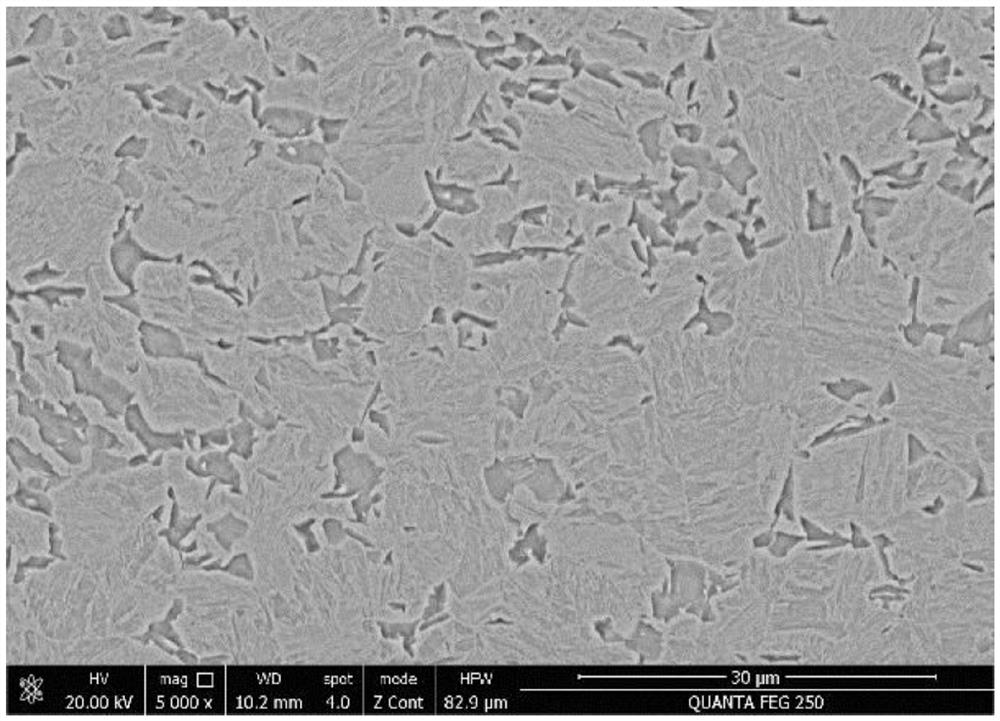

Image

Examples

Embodiment Construction

[0061] The present invention will be described in more detail below with reference to exemplary embodiments. The following examples or experimental data are intended to illustrate the present invention, and it should be clear to those skilled in the art that the present invention is not limited to these examples or experimental data. In addition, the descriptions about the contents of chemical elements in the text all refer to percentages by weight.

[0062] The main chemical composition of the matrix steel plate that the present invention adopts is described in detail as follows:

[0063] C: about 0.08wt%~0.45wt%,

[0064]C is the most effective solid solution strengthening element in steel. In order to ensure the tensile strength of the steel is above 1000MPa, the carbon content is required to be greater than or equal to about 0.08wt%. However, if the carbon content exceeds 0.45wt%, its microstructure is mainly brittle high-carbon martensite, its ductility and toughness ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com