Edge cutting equipment for food bag processing

A food bag and edge trimming technology, applied in packaging and other directions, can solve problems such as uneven trimming, affecting the trimming of food bags, and inability to clean up leftovers in time, and achieves the effects of avoiding damage, easy operation and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

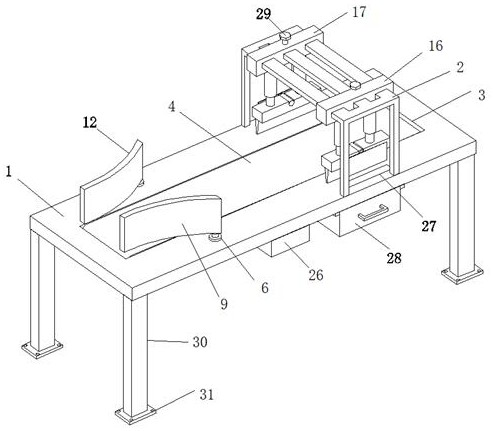

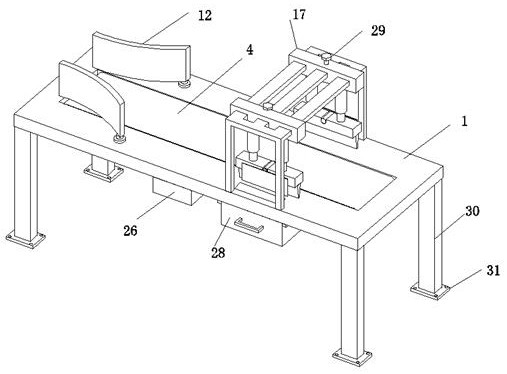

Embodiment 1

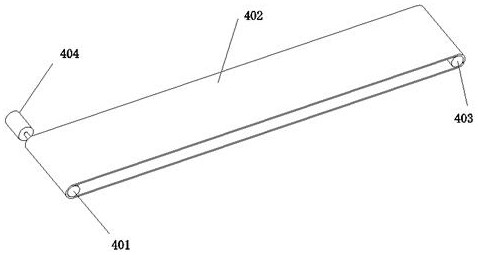

[0035] The working process of Embodiment 1 is as follows: firstly, the expansion and contraction of the first electric push rod 15 can be controlled to drive the double-sided rack 14 to move left or right, and then the first gear 10 and the second gear 13 can be driven by a pair of intermediate gears Simultaneously turn to the opposite direction, thereby the opening and closing angle between the front guide piece 9 and the rear guide piece 12 can be further adjusted; then a stack of plastic bags to be trimmed is placed on the conveyor belt 402 upper surface, and then the driving motor 404 is controlled to work The plastic bag is sent to the right below the frame 2; then the hydraulic cylinder 18 is controlled to drive the knife seat 19 and the blade 20 to move down and cut the food bag. The blade 20 just touches the surface of the workbench 1, and the proximity position sensor 24 will send two signals to the control box 26 on the lower end of the workbench 1. One signal can sto...

Embodiment 2

[0038] Embodiment 2 is on the basis of embodiment 1, as Figure 6 and Figure 7 As shown, the opposite sides of the two tool holders 19 are also fixed with a pressure bag assembly 5, the pressure bag assembly 5 includes a fixed plate 501, a return spring 502, a connecting rod 503 and a pressure plate 504, and the surface of the fixed plate 501 is equidistantly provided with A plurality of round holes 505, each round hole 505 is sleeved with a connecting rod 503, the top of the connecting rod 503 is fixed with a top cap 506, the bottom of the connecting rod 503 is fixed with a pressure plate 504; the return spring 502 is sleeved on the connecting rod 503 , and the return spring 502 is disposed between the lower surface of the fixing plate 501 and the upper surface of the pressing plate 504 .

[0039] Embodiment 2 When the blade 20 cuts the food bag, the pressing plate 504 will first touch the upper surface of the food bag, and as the knife seat 19 and the blade 20 continuously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com