A kind of magnetic nanocrystalline glass solder and its preparation method and the method of using it to connect ferrite

A kind of glass solder and magnetic nano technology, which is applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of contradictory sustainable development concept, high connection temperature, and high softening temperature of magnetic glass, so as to ensure service stability , reduce the connection temperature, the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

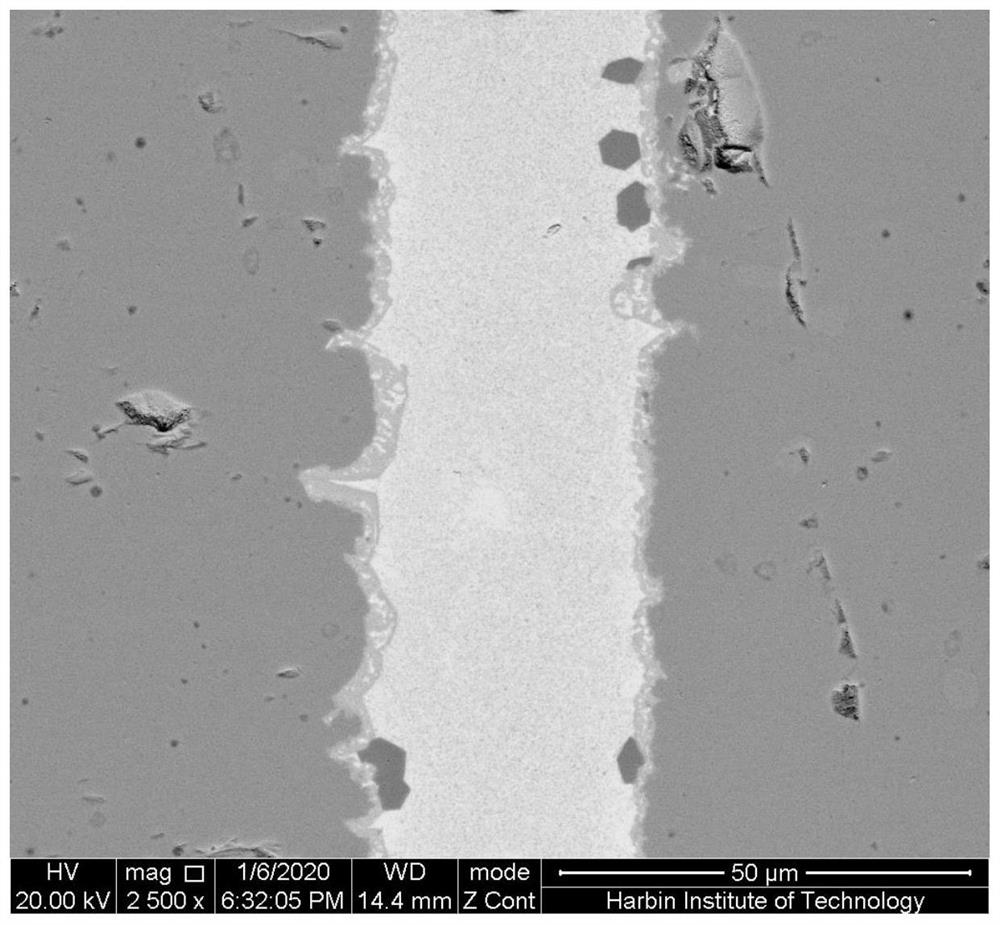

[0030] 1. Analytical pure Bi 2 o 3 , CoO, Fe 2 o 3 and H 3 BO 3 Mix according to the mole percentage of 40:25:25:10, melt and cast it in a stainless steel grinding tool at 1200°C and keep it warm for 1h. Magnetic nanocrystalline glass solder.

[0031] 2. Cut the magnetic nanocrystalline glass solder into 1mm-thick solder sheets with a diamond wire saw. Then the 1mm-thick brazing material sheet was polished with #600, #800 and #1200 sandpaper in sequence, and then polished with a diamond polishing agent with a particle size of 1 μm at a speed of 500-600r / min to obtain a brazing filler metal with a thickness of 500 μm. sample.

[0032] 3. Cut the YIG cylindrical base material with a diameter of 9mm into a sample with a thickness of 2mm, and polish the surface of the base metal to be welded with #600, #800 and #1200 sandpaper in turn, and then use a diamond polishing agent with a particle size of 1μm. Polishing at a speed of 500-600r / min, and then pre-treating the surface...

specific Embodiment approach 2

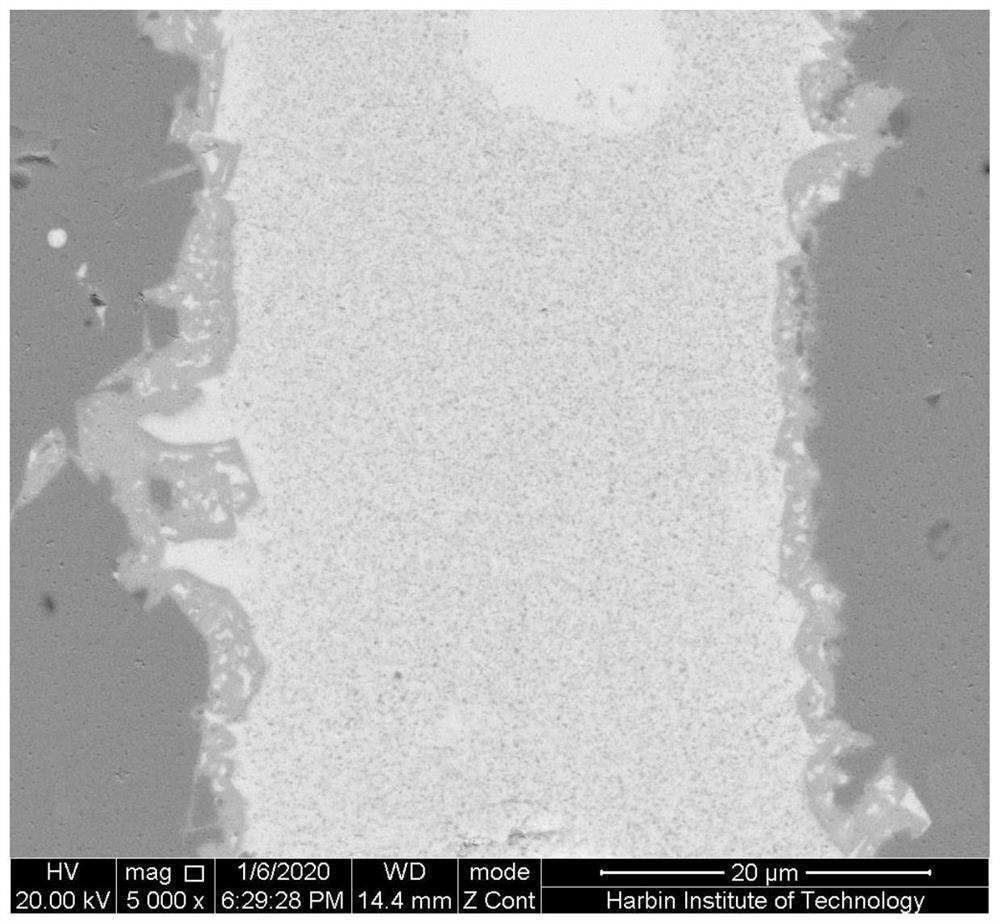

[0036] 1. Analytical pure Bi 2 o 3 , CoO, Fe 2 o 3 and H 3 BO 3 Mix according to the mole percentage of 30:30:30:10, melt and cast it in a stainless steel grinding tool at 1200°C and keep it warm for 1h. Magnetic nanocrystalline glass solder.

[0037]2. Cut the magnetic nanocrystalline glass solder into 1mm-thick solder sheets with a diamond wire saw. Then the 1mm-thick brazing material sheet was polished with #600, #800 and #1200 sandpaper in sequence, and then polished with a diamond polishing agent with a particle size of 1 μm at a speed of 500-600r / min to obtain a brazing filler metal with a thickness of 500 μm. sample.

[0038] 3. Cut the YIG cylindrical base material with a diameter of 9mm into a sample with a thickness of 2mm, and polish the surface of the base metal to be welded with #600, #800 and #1200 sandpaper in turn, and then use a diamond polishing agent with a particle size of 1μm. Polishing at a speed of 500-600r / min, and then pre-treating the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com