High-strength step-stone-imitating antique concrete stone and manufacturing process thereof

A production process and high-strength technology, applied in the direction of manufacturing tools, mold fixtures, ceramic molding machines, etc., can solve the problems of damage, low strength of stepping stones, easy cracking, etc., and achieve high strength, realistic effect, and not easy to crack Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

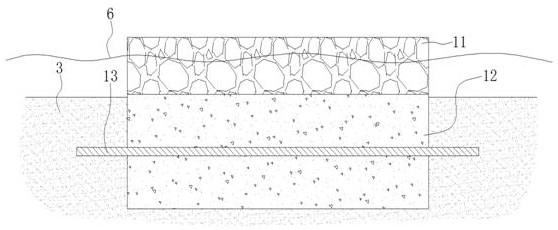

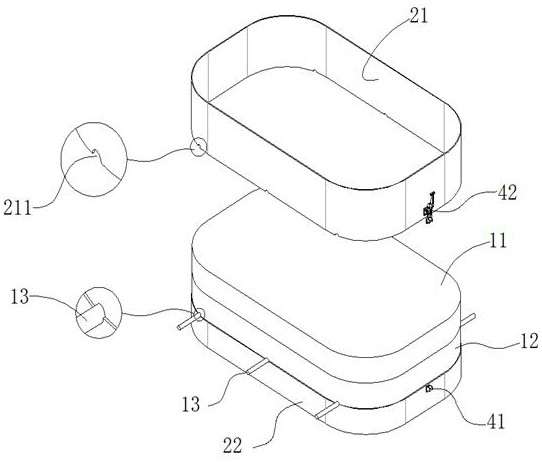

[0057] Embodiment 1: The base layer 12 is made of the following raw materials in parts by weight: 1 part of cement, 3 parts of sand, 0.5 part of yellow iron oxide pigment, 1.8 parts of water and 0.5 parts of additives. The gray concrete of the surface layer includes 0.5 parts of cement, 2 parts of sandstone, 0.1 part of iron oxide gray pigment, 0.8 part of water and 0.1 part of additives, and the yellow concrete contains 0.5 part of cement, 2 parts of sandstone, 0.1 part of iron oxide yellow pigment, 0.8 part of water and 0.1 part of additive.

Embodiment 2

[0058] Embodiment 2: the base layer 12 is made of the following raw materials in parts by weight: 2 parts of cement, 6 parts of sandstone, 0.5 part of iron oxide yellow pigment, 2 parts of water and 0.6 part of additive; the gray concrete of the surface layer 11 includes There are 1 part of cement, 3 parts of sand and gravel, 0.3 parts of iron oxide gray pigment, 1 part of water and 0.2 parts of additives. The yellow concrete contains 1 part of cement, 3 parts of sand and gravel, 0.3 part of iron oxide yellow pigment, and 1 part of water and 0.2 parts of additives.

Embodiment 3

[0059] Embodiment 3: The base layer 12 is made of the following raw materials in parts by weight: 3 parts of cement, 8 parts of sand, 1 part of iron oxide yellow pigment, 2.5 parts of water and 1 part of additive. The gray concrete of the surface layer includes 1.2 parts of cement, 4 parts of sand and gravel, 0.5 parts of iron oxide gray pigment, 1.2 parts of water and 0.5 parts of additives. The yellow concrete includes 1.2 parts of cement, 4 parts of sand and gravel, iron oxide 0.5 parts of yellow pigment, 1.2 parts of water and 0.5 parts of additives.

[0060] The raw materials of the above-mentioned three examples are respectively used to produce the retro-style concrete stone imitating Tingbu by the above-mentioned process, wherein Example 1 is produced to form the retro-style concrete stone A imitating Tingbu, Example 1 is produced to form the retro-style concrete stone B imitating Tingbu, and Example 1 Made to imitate Tingbu retro concrete stone c.

[0061] Put the imi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com