Lyocell fiber, Lyocell fiber antigen fibrillation cross-linking agent, and method for treating Lyocell fiber antigen fibrillation

A treatment method and cross-linking agent technology, applied in the direction of fiber treatment, plant fiber, wear-resistant fiber, etc., can solve the problems affecting wearing and look and feel, and achieve the effect of enhancing lateral force and strong anti-fibrillation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

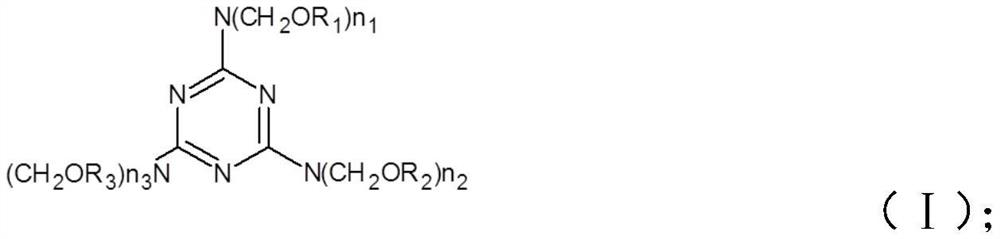

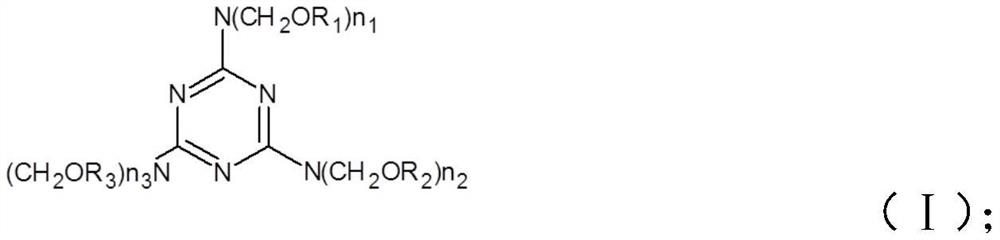

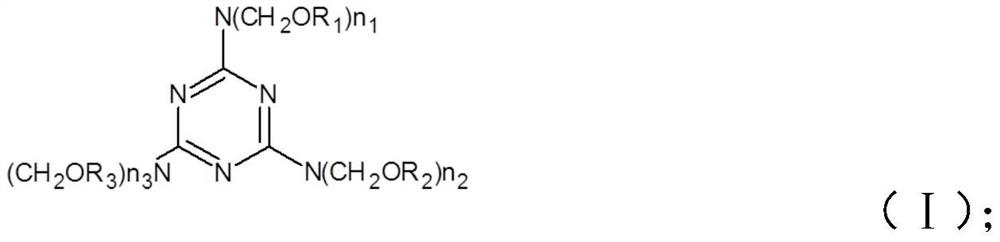

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Immerse the fiber in the prepared cross-linking solution, the concentration of butanol-etherified melamine in the cross-linking solution is 8%, the concentration of dinonyl naphthalene disulfonic acid catalyst is 1%, two dipping and two rolling, and the pass ratio is controlled at 120% After curing for 30 minutes at a certain curing temperature, washing with water three times, and drying at 85°C, the lyocell fiber with anti-fibrillation ability was obtained. The obtained fiber was measured for wet wear value, and the blank sample was the fiber without cross-linking treatment. The results are shown in Table 1.

[0042] Table 1 Data table for the effect of curing temperature on wet abrasion values

[0043] temperature / ℃ Wet wear value (r / dtex) 120 302.92 130 436.71 140 515.97 150 639.79 160 375.43 blank sample 55.78

[0044] Compared with the blank sample, under certain conditions, after cross-linking, the wet wear value of t...

Embodiment 2

[0046] Immerse the fiber in a cross-linking solution with a certain concentration of butanol-etherified melamine, with a methanesulfonic acid catalyst concentration of 1%, three dips and three rollings, and the scrapping rate is controlled at about 140%, cured at 120°C for 5 minutes, and washed four times , and dried at 95°C to obtain lyocell fibers with anti-fibrillation ability. The obtained fiber is measured for wet wear value, and the blank sample is the fiber without cross-linking treatment, the results are shown in Table 2:

[0047] Table 2 Influence data sheet of butanol etherified melamine concentration on wet wear value

[0048]

[0049]

[0050] With the increase of the concentration of butanol-etherified melamine, the wet wear value gradually increased. When the concentration of butanol-etherified melamine reached 6wt%, the wet wear value reached 802.92. Compared with the blank sample, the wet wear value increased by 1330.47%. Far exceeds the wet abrasion value...

Embodiment 3

[0052] The fibers are immersed in the prepared cross-linking solution, the concentration of butanol-etherified melamine in the cross-linking solution is 4%, the concentration of HMMM is 4%, and the concentration of the mixed catalyst of p-toluenesulfonic acid and dodecylbenzenesulfonic acid is 1 %, two dipping and two rolling, the excess rate is controlled at about 160%, curing at 150°C for a certain period of time, washing twice, and drying at 85°C to obtain lyocell fibers with anti-fibrillation ability. The obtained fiber is measured for the wet abrasion value, and the blank sample is a fiber without cross-linking treatment, and the results are shown in Table 3:

[0053] Table 3 data table of the influence of curing time on the wet wear value

[0054] time / min Wet wear value (r / dtex) 10 471.63 15 1535.99 20 1493.94 25 1557.11 30 1669.98 blank sample 55.34

[0055] As the curing time increases, the wet wear value increases gradu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com