Pulse jet generator, generating device, water injection and blockage removal integrated pipe column and method

A technology of pulse jet and generating device, which is applied in the fields of generating device, water injection and plugging removal integrated pipe string, and pulse jet generator, which can solve the problems of constant water flooding affected area, dependence on plugging removal effect, and high investment cost, and achieve expansion The effect of water flooding sweeping area, increasing action radius and action intensity, and reducing probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

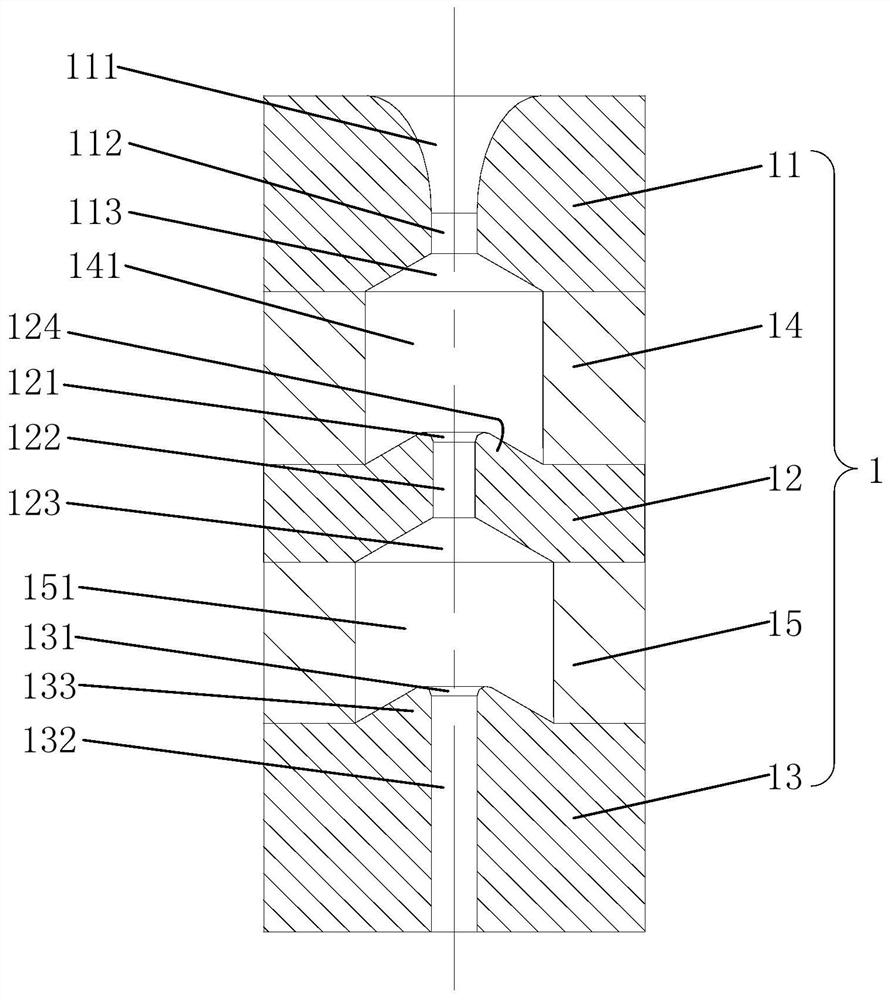

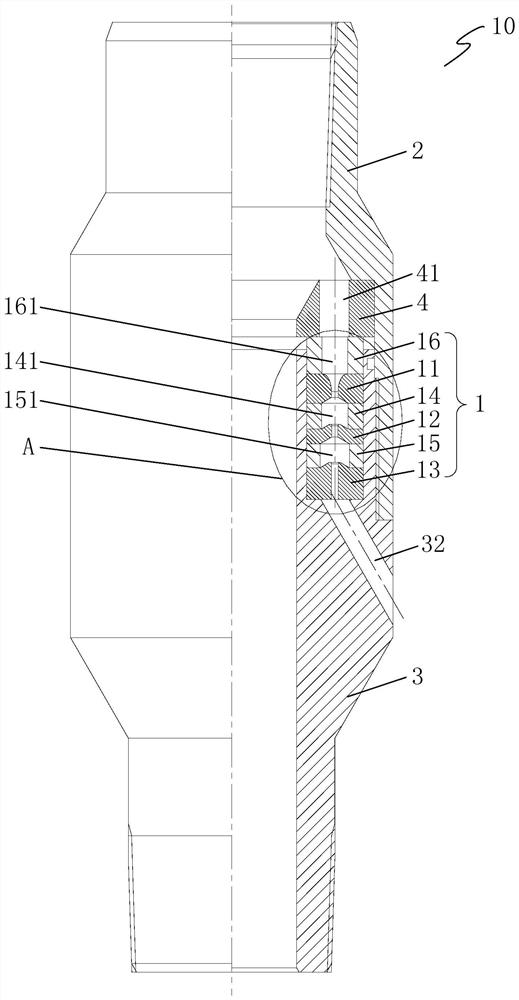

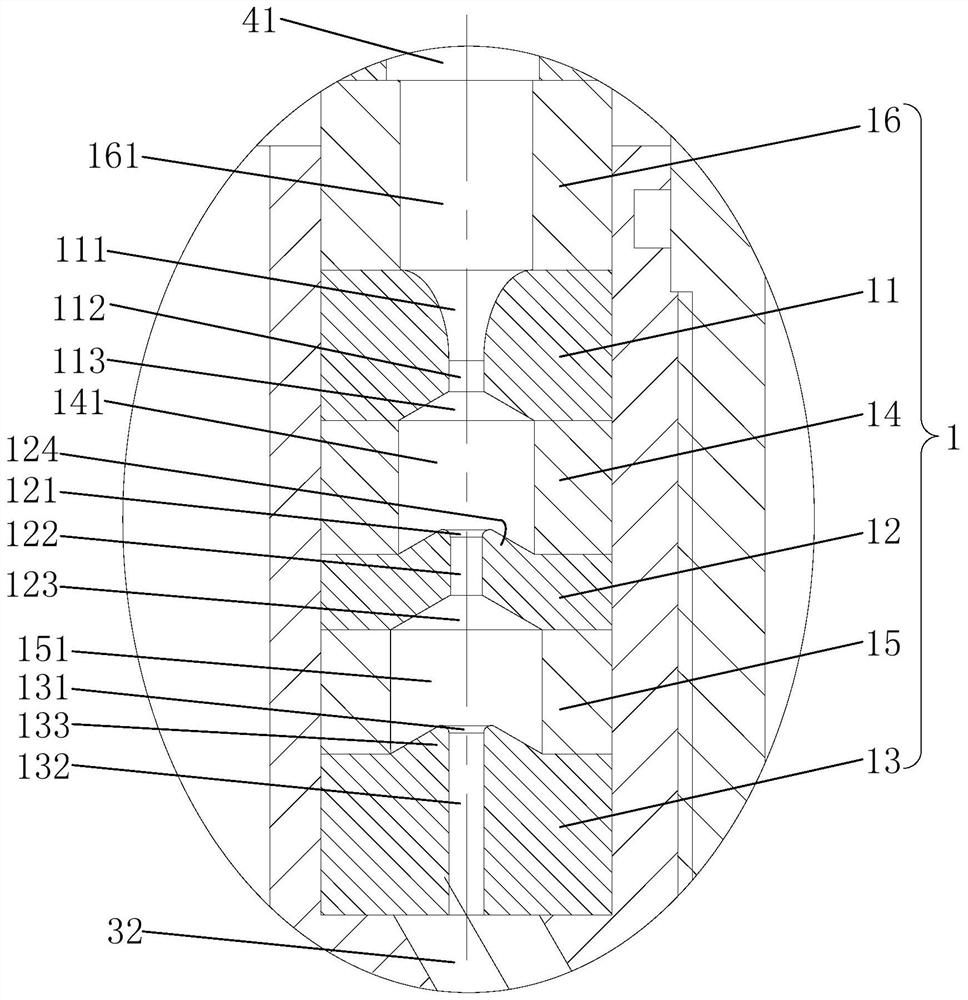

[0069] Such as figure 2 , image 3 , Figure 4 As shown, the present invention also provides a pulse jet generating device 10 for stratified water injection and plugging removal. The pulse jet generating device 10 includes a cylindrical first upper joint 2 and a cylindrical main body 3 that can be connected in series on the oil pipe. With the above-mentioned pulse jet generator 1, the upper end of the main body 3 is connected to the lower end of the first upper joint 2, and the upper end side wall of the main body 3 is provided with an installation cavity 31 communicating with the first upper joint 2, and in the side wall of the main body 3 A drain hole 32 is also provided, and the drain hole 32 extends from the bottom of the installation cavity 31 to the outer wall of the main body 3, and communicates the installation cavity 31 with the outside of the main body 3, and the pulse jet generator 1 is fixed in the installation cavity 31, and It communicates with the first upper...

Embodiment approach 2

[0086] Such as Figure 6 As shown, the present invention also provides a pulse jet generating device 10', which is used for general water injection and plugging removal. The jet generator 1 is fixed in the outer cylinder 5 , the stable continuous fluid flows into the pulse jet generator 1 through the upper inlet of the outer cylinder 5 , and the pulsed jet ejected from the third nozzle 13 is discharged through the lower outlet of the outer cylinder 5 .

[0087] In the present invention, general water injection is performed by setting a pulse jet generator 1 in the outer cylinder 5. The pulse jet generator 1 converts the stable continuous fluid into a pulse jet, increases the energy of the liquid, and overcomes the shortcoming of the small continuous energy of the stable continuous fluid. No additional energy action is required.

[0088] During general water injection, the pulse jet generator 1 causes the injected water to produce a pulse oscillation effect, so that the inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com