A Diesel Catalyst with National VIB Structure

A catalytic converter and diesel technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., to achieve good effects, sufficient mixing, and space-saving layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

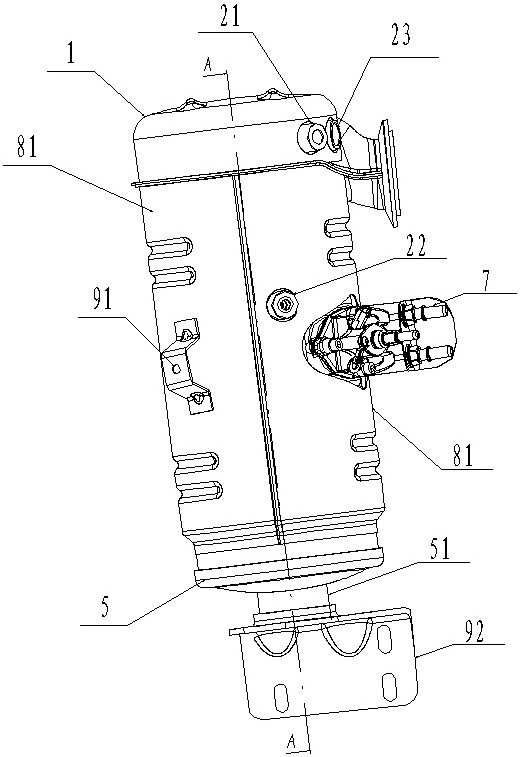

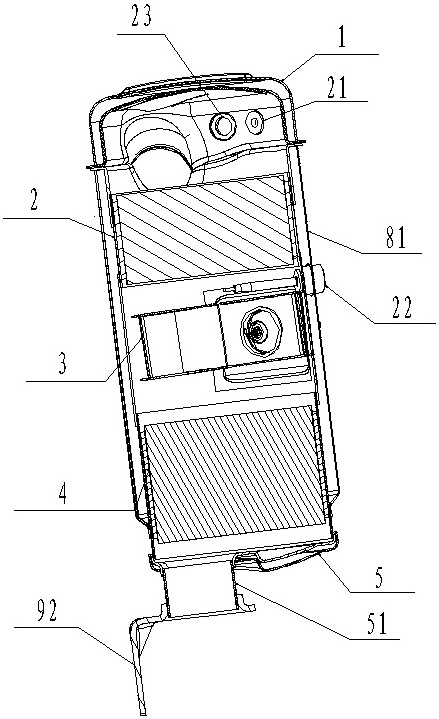

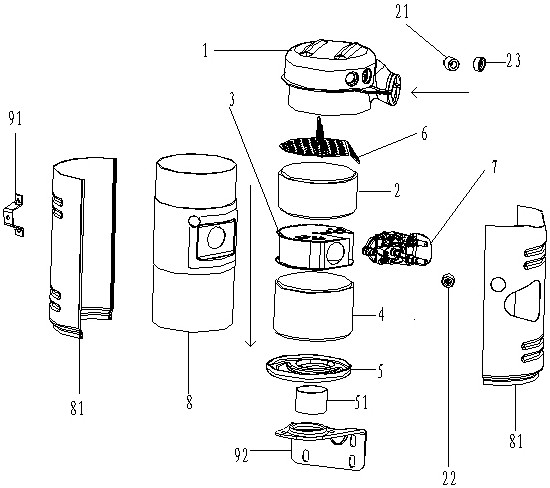

[0044] Such as Figure 1 to Figure 7 As shown, a catalytic converter with a new structure of the national six b for diesel in this embodiment includes an air intake end cover 1, a DOC carrier 2, a urea mixer 3, an SCR carrier 4 and an air outlet end cover 5 arranged in sequence along the axial direction of the catalytic converter. , also includes deflector 6 and urea nozzle 7.

[0045] Wherein, the deflector 6 is located between the air intake end cover 1 and the DOC carrier 2 . The DOC carrier 2 , the urea mixer 3 and the SCR carrier 4 are wrapped by an encapsulation casing 8 .

[0046] The urea nozzle 7 is connected to the side of the urea mixer 3, and the function of the urea nozzle is to spray urea into the exhaust gas in the form of mist according to the required amount under the control of the ECU.

[0047] The urea mixer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com