an air conditioning unit

A technology for air-conditioning units and compressors, applied in refrigerators, compressors, refrigeration components, etc., can solve the problems of small pressure difference in the cooling system for supplying refrigerants, different working stages of power modules, and different heat dissipation, etc., to improve the temperature uniformity. , expand the working temperature area, and achieve the effect of differential adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

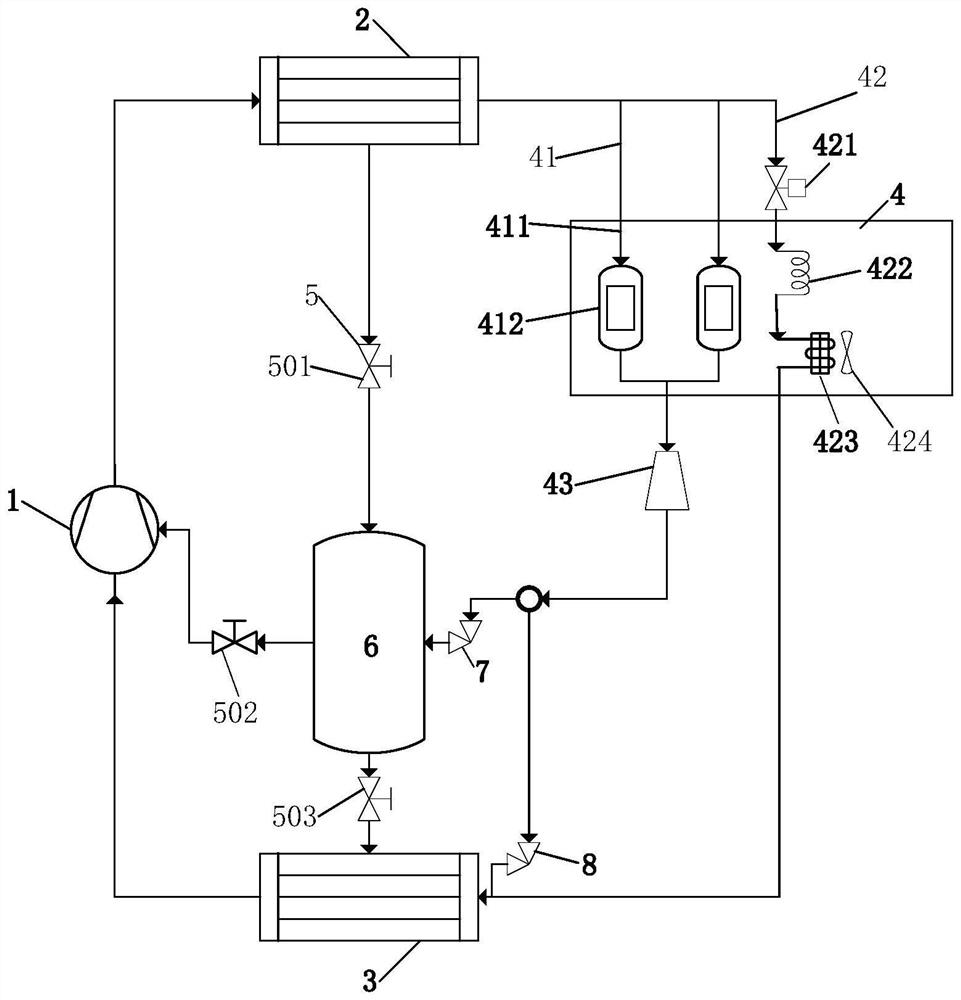

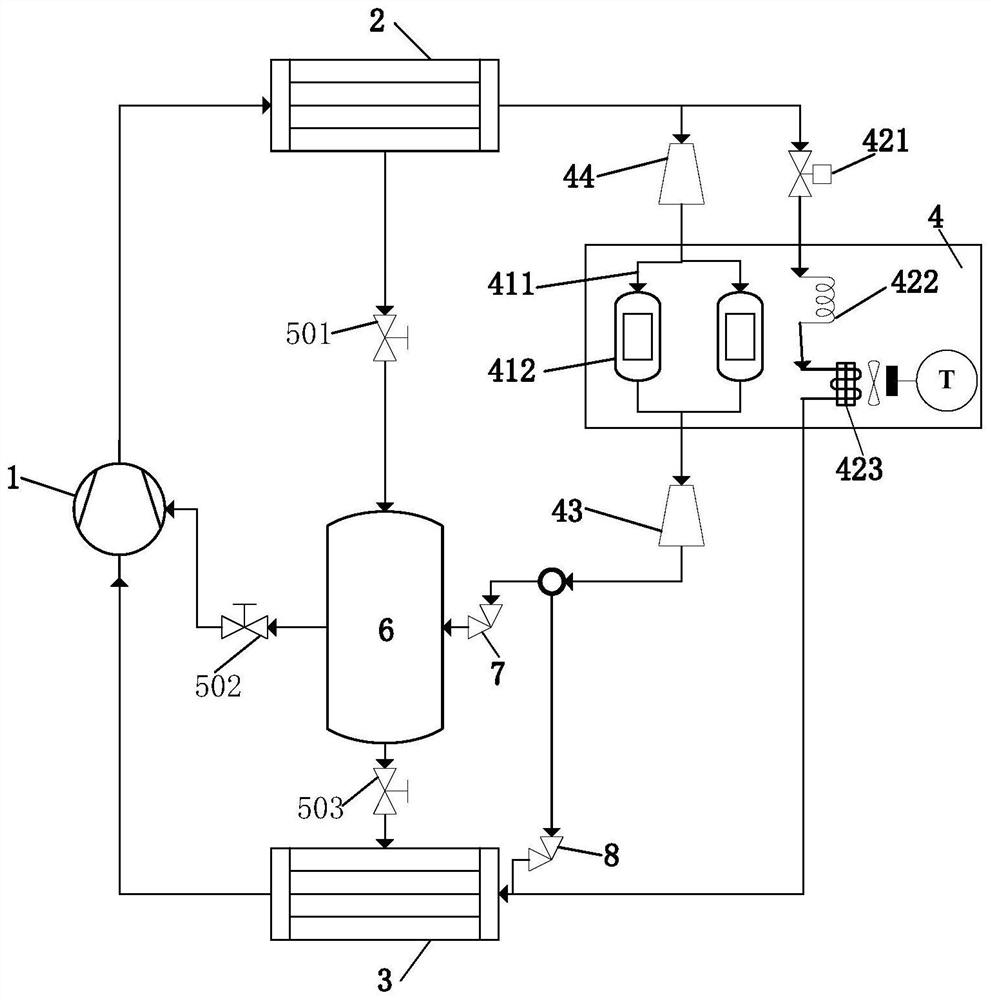

[0029] like figure 1 As shown, the air conditioning unit of this embodiment includes a refrigeration system and a frequency converter. The refrigeration system includes a compressor 1, a condenser 2, a main evaporator 3, a flasher 6 and a throttling unit 5. The inlet end of the compressor 1 is connected to the The main evaporator 3 is connected, the outlet end is connected to the condenser 2, the throttle unit 5 includes a first throttle element 501, a second throttle element 502 and a third throttle element 503, the first throttle element 501 is located in the condenser 2 Between the flasher 6, the second throttle element 502 is located between the compressor 1 and the flasher 6, the third throttle element 503 is located between the flasher 6 and the main evaporator 3, and the inverter is provided with The inverter cooling unit 4, the inlet end of the inverter cooling unit 4 is connected to the condenser 2, the outlet end of the inverter cooling unit 4 is connected to the fla...

Embodiment 2

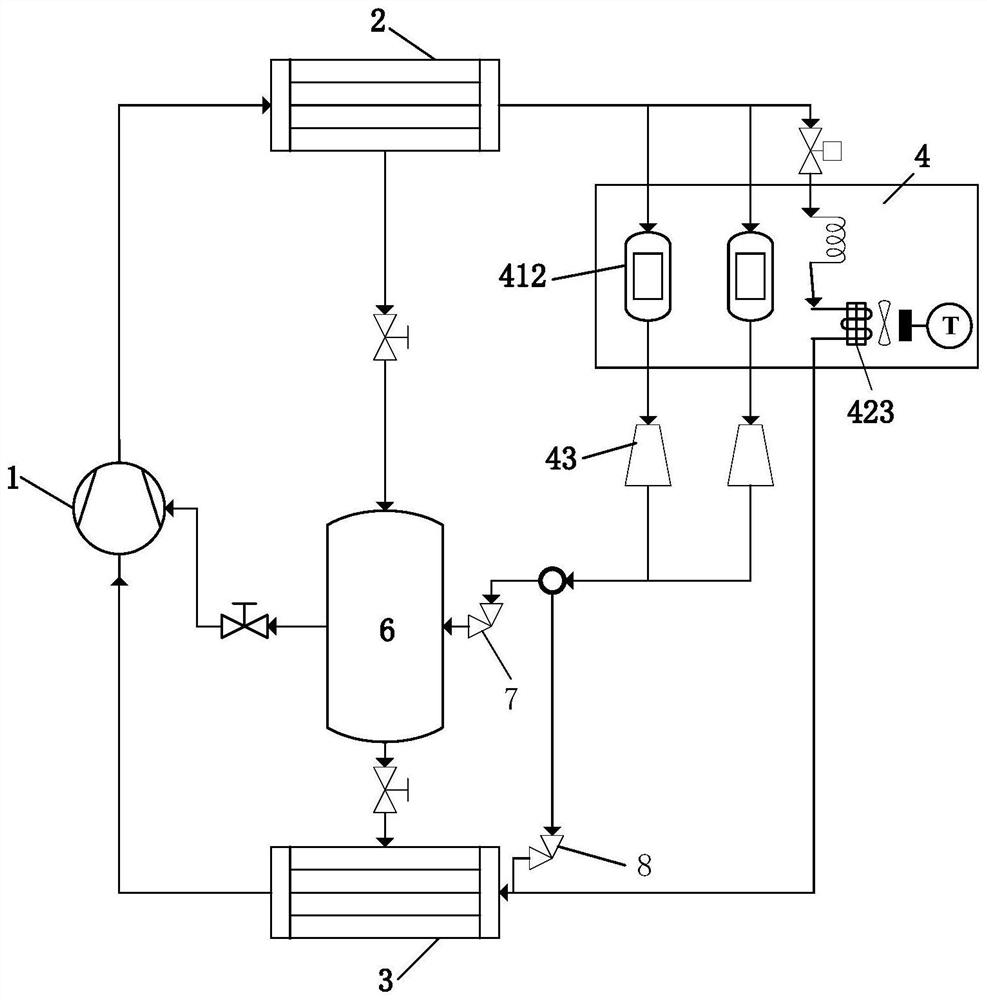

[0040] like image 3 As shown, the difference between this embodiment and the first embodiment is that the installation positions of the first switch module 43 and the second switch module 44 are different. In this embodiment, each cooling branch 411 is provided with the first switch module 43 or and / and the second switch module 44 , specifically, each cooling branch 411 is provided with a cooler 412 and a first switch module 43 , and each first switch module 43 is located on the cooling branch 411 corresponding to the outlet end of the cooler 412 . A first switch module 43 is configured on each cooling branch 411 , which can independently adjust each cooling branch 411 , improve the temperature uniformity of the cooler 412 , and realize differential adjustment, which is suitable for the loss of each cooling branch 411 There are certain differences (for example, the heat dissipation of the power devices is different); on this basis, the first switch module 43 is located downst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com