Ultrasonic pre-tightening force measuring method for bolt made of low-elasticity-modulus material

A technology with low elastic modulus and bolt pre-tightening force, applied in force/torque/power measuring instruments, measuring torque/torsion force during tightening, measuring devices, etc., can solve the problems of small elastic modulus and cannot be ignored, and achieve The effect of improving measurement accuracy, reducing the number of fitting iterations, and improving calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

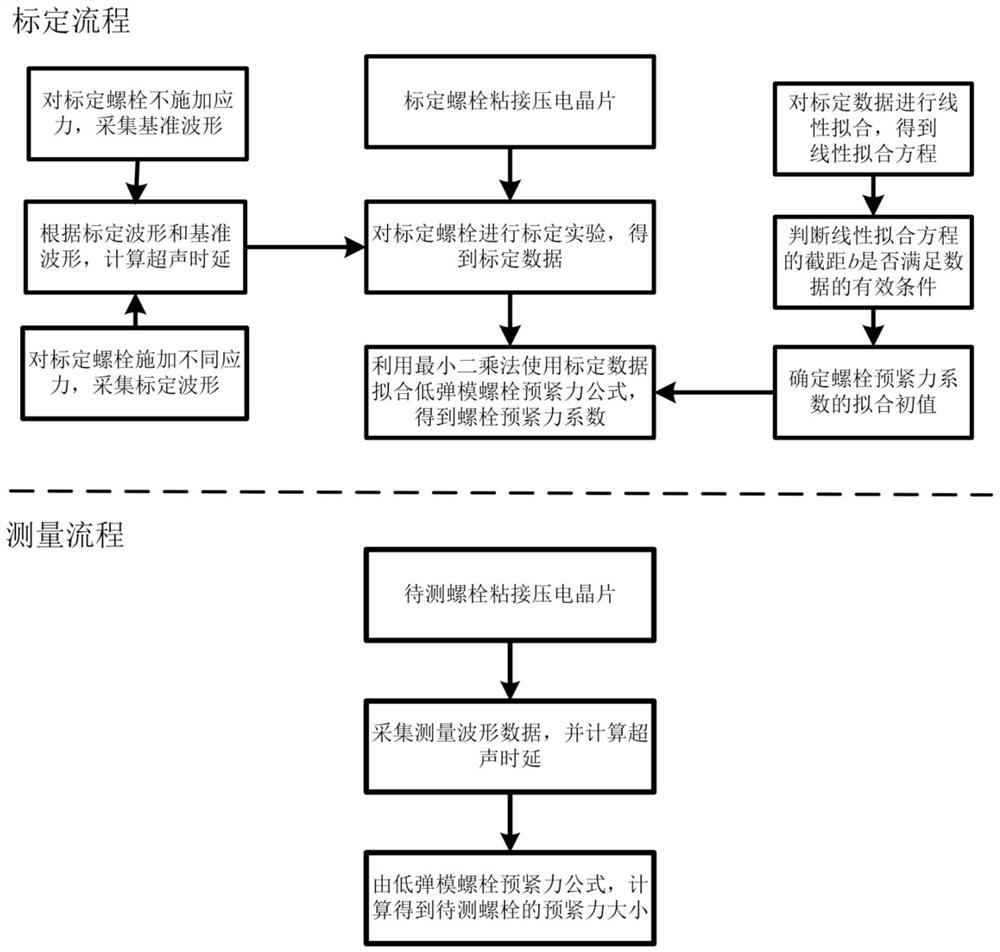

[0086] Use this method to measure the pretightening force of aluminum bolts with a diameter of 20mm, figure 1 It is the flow chart of ultrasonic preload measurement of low elastic modulus material bolts in this example, including the calibration process and measurement process. The following is a detailed description step by step:

[0087] S1. Select any aluminum bolt with a diameter of 20 mm and the same specification and batch as the bolt to be tested as the calibration bolt.

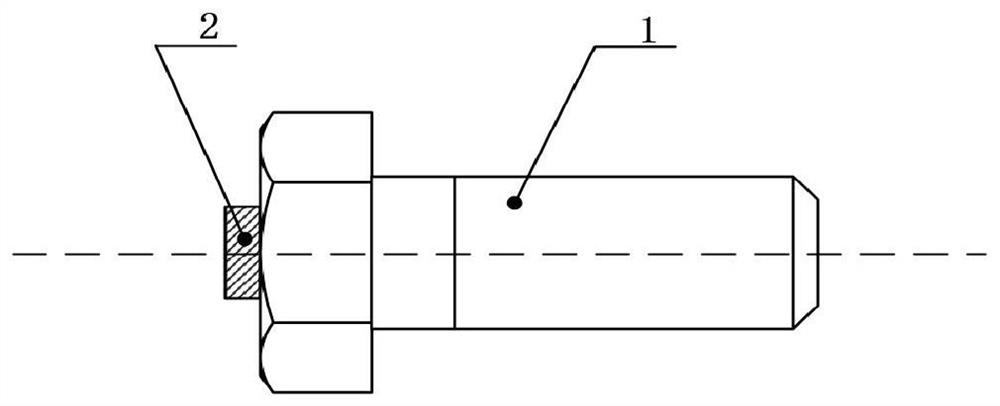

[0088] There is also a step between step S1 and step S2: grinding the end face of the calibration bolt to meet the requirement that the surface roughness is less than 3.2 μm, and bonding the circular piezoelectric wafer with thread fastening glue on the polished end face , while ensuring that the end faces of the circular piezoelectric wafer and the bolt are concentric, and its structure is as follows figure 2 shown.

[0089] S2. In the state of zero stress, use the spontaneous self-receiving mode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com