Transmission shaft machining performance evaluation and key process-based control method

A processing performance and control method technology, applied in the direction of comprehensive factory control, genetic rules, gene models, etc., can solve the problems of limited evaluation indicators, inaccurate, difficult process parameter optimization, etc., achieve accurate service life, and expand the effect of optimization range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

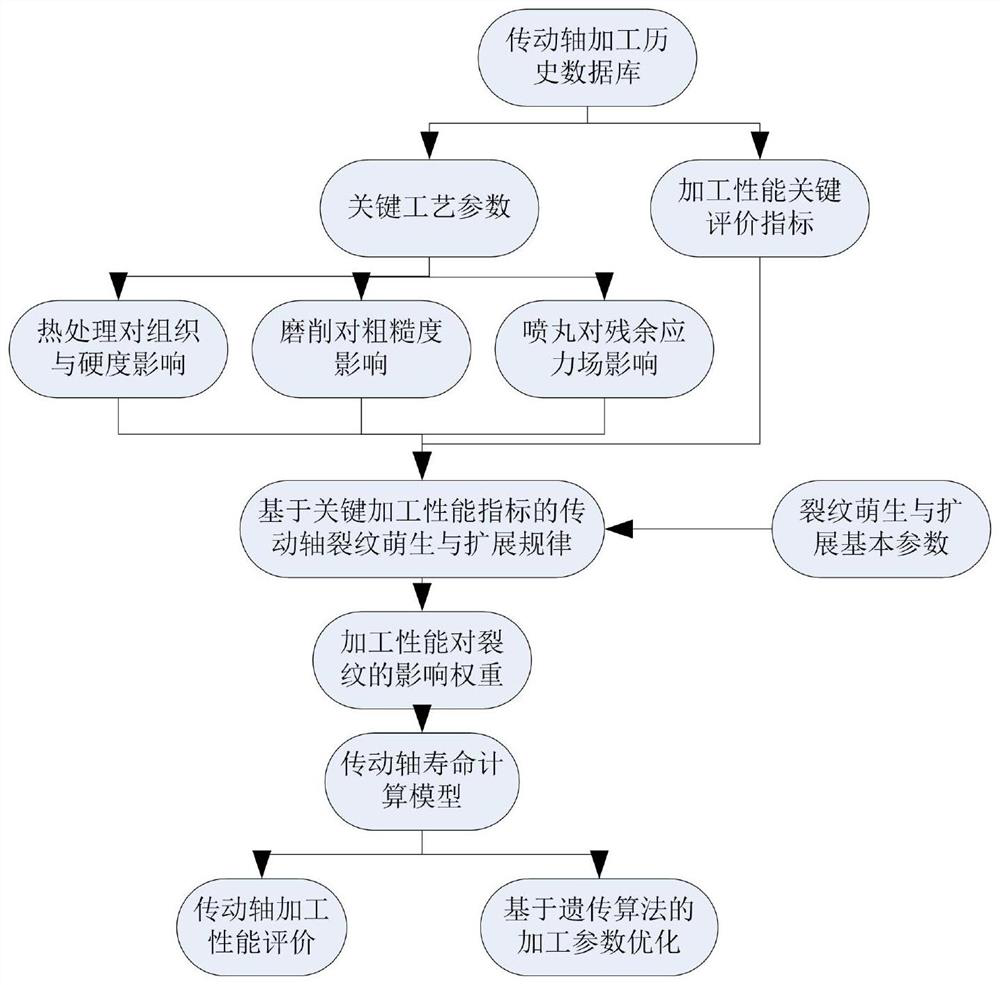

[0027]The present invention is a transmission shaft processing performance evaluation and a control method based on a critical process, and the method flow is as follows:

[0028]Step S1: Key Process Parameters and Processing Performance Key Evaluation Indexes in Transmission Manufacturing;

[0029]Step S2: Based on simulation and experimental analysis, the impact law of key process control parameters on its performance evaluation index is obtained;

[0030]Step S3: The impact law of the cracks and the impact weight of the cracks are studied on the basis of obtaining the correlation parameters of the crack germination and expansion of the drive shaft.

[0031]Step S4: The transmission shaft processing performance evaluation index is an intermediate variable, and the transmission shaft life calculation model is constructed;

[0032]Step S5: Optimize the drive shaft key pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com