Flat coil carrier

A flat coil and carrier technology, applied in the direction of coils, transformers/inductor coils/windings/connections, other household appliances, etc., can solve complex, flat coil manufacturing and corresponding application complex problems, to improve accuracy and quality, easy Pre-Assembled, Easy-to-Manufacture Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

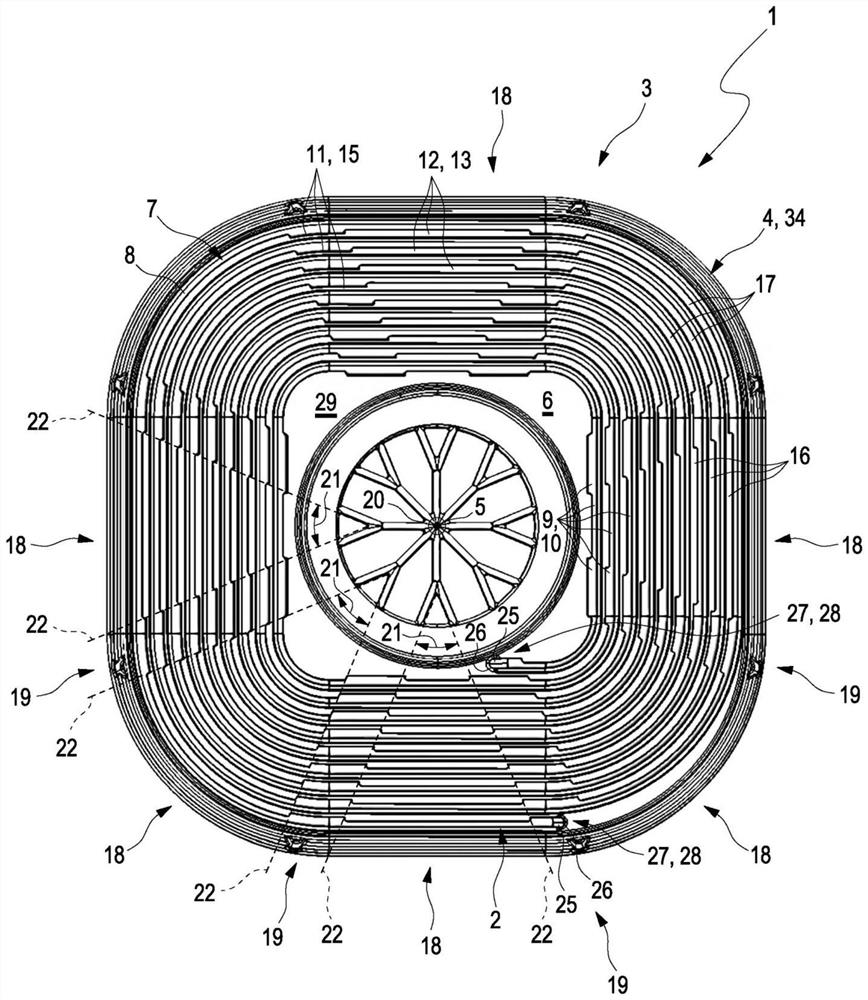

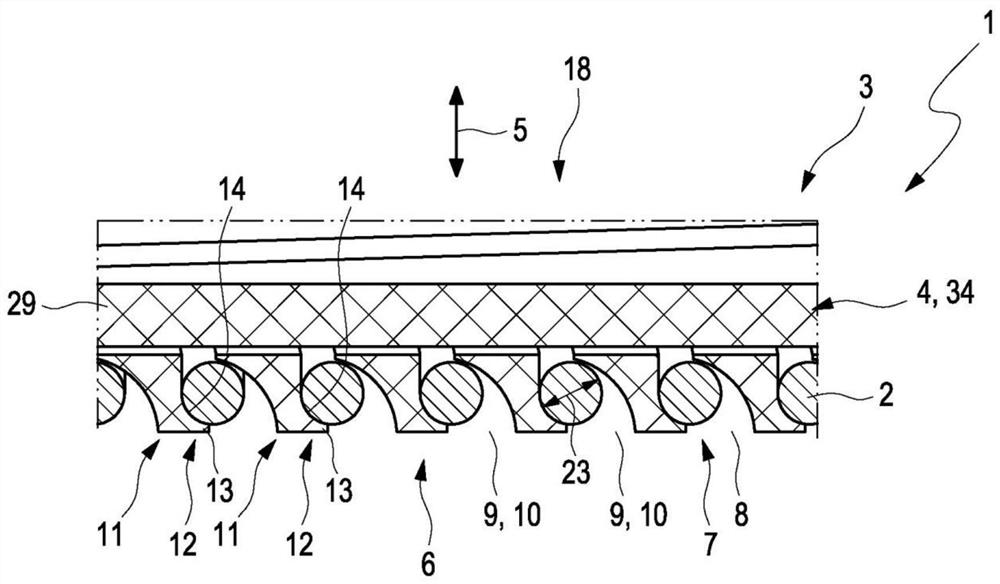

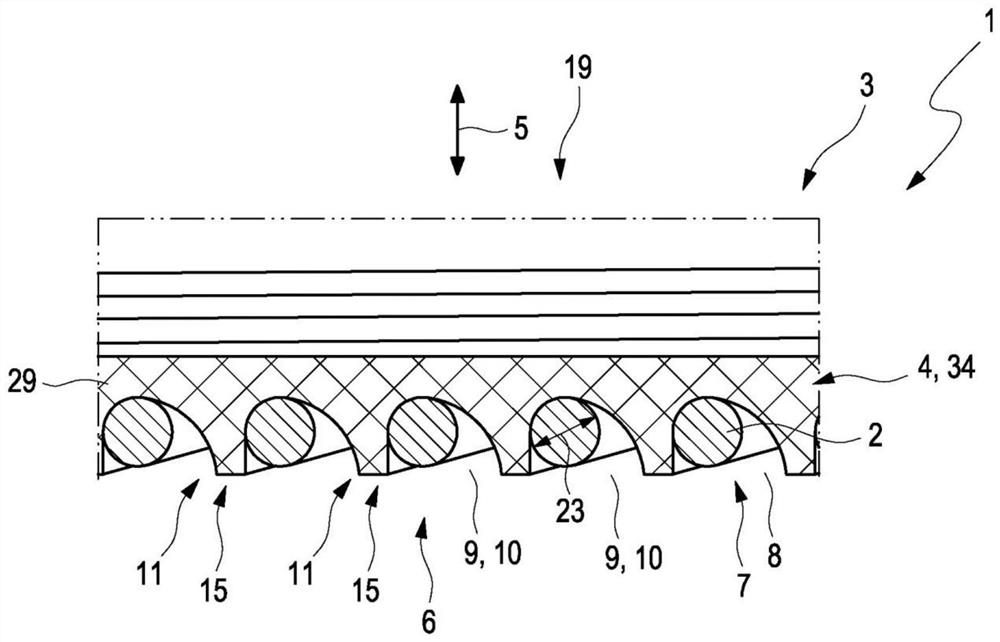

[0048] For example Figure 1 to Figure 4 As shown, the flat coil 1 has a coil wire 2 extending in a helical and flat manner, which is accommodated in a carrier 3 of the flat coil 1 , which is also referred to below as the flat coil carrier 3 . The flat coil carrier 3 has a carrier body 4 which is formed in a plate-like manner. The carrier body 4 extends in a plane substantially perpendicular to the axial direction 5 . To accommodate the coil wire 2 , the carrier body 4 has a groove spiral 7 on the axial front side 6 , which extends helically in line with the course of the coil wire 2 . The groove spiral 7 thus extends on the carrier body 4 transversely to the axial direction 5 . The groove spiral 7 thus has an axially open groove opening 8 . Due to the helical course of the groove spiral 7 , the groove spiral 7 has radially continuous groove sections 9 , wherein the respective groove section 9 each has or forms a part of the groove opening 8 , wherein this part is also refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com