Auxiliary conveying device for cable laying

A conveying device and cable laying technology, which is applied in the direction of cable laying equipment and the arrangement of reels/photosensitive drums, etc., can solve the problems of cable wear and tear, increase labor intensity, and complicated laying process, so as to reduce drag Effects of friction, reduction of cable clutter, and improvement of laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

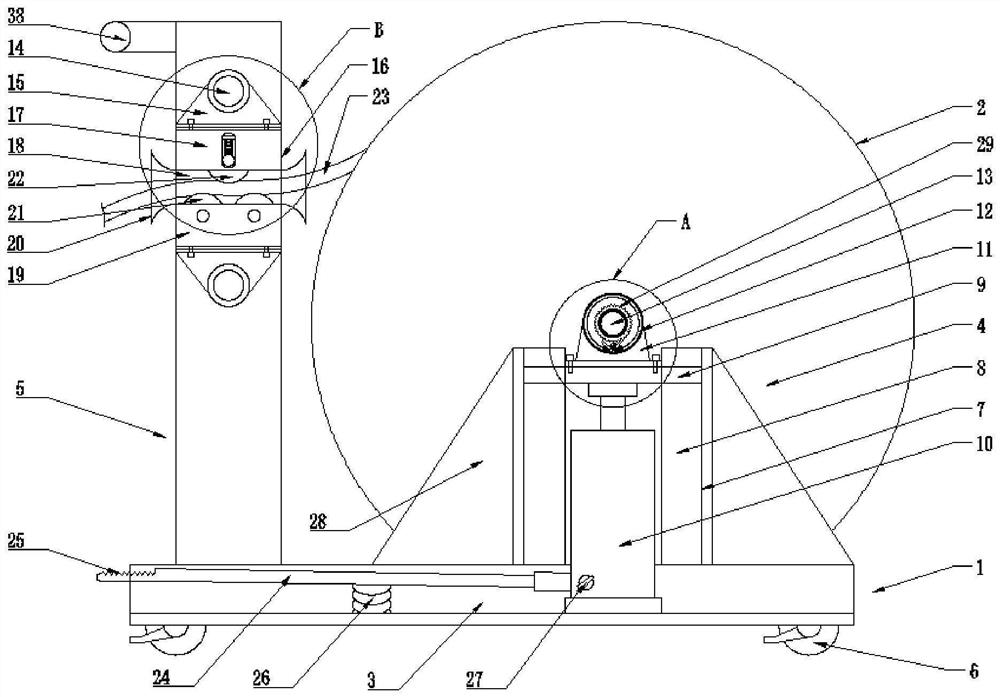

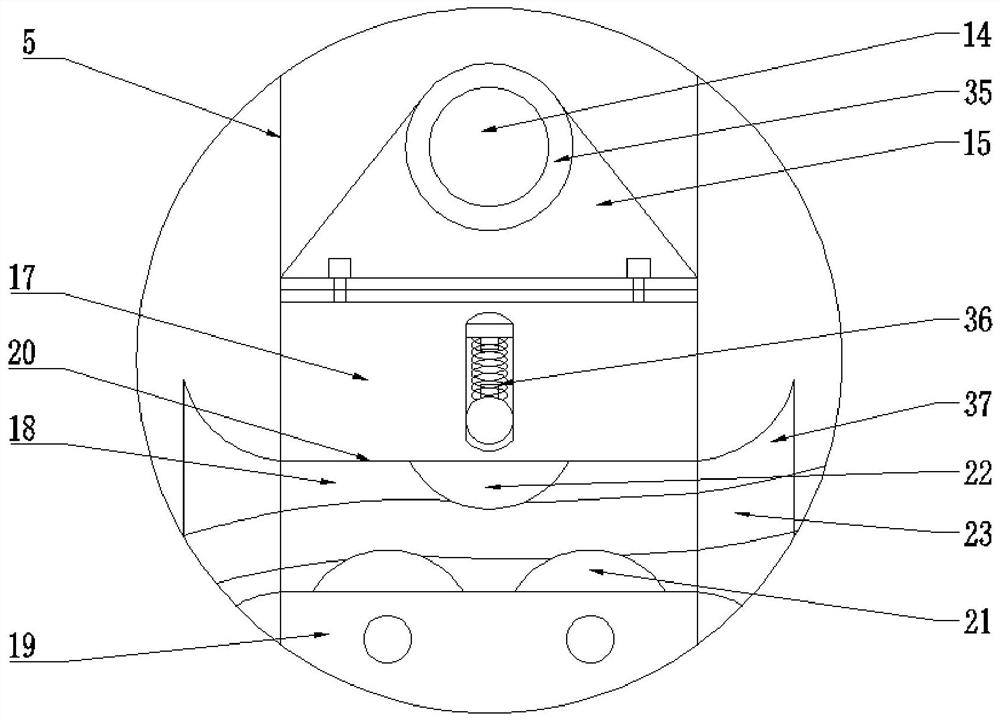

[0029] Such as Figure 1-5 As shown, an auxiliary conveying device for cable laying includes a bracket forklift 1 and a cable drum 2. The bracket forklift includes a chassis 3, two sets of top brackets 4 and a cable management frame 5. The chassis is a horizontal "匚" with an opening on the right side. shaped frame, a caster 6 is respectively provided below the four corners of the chassis.

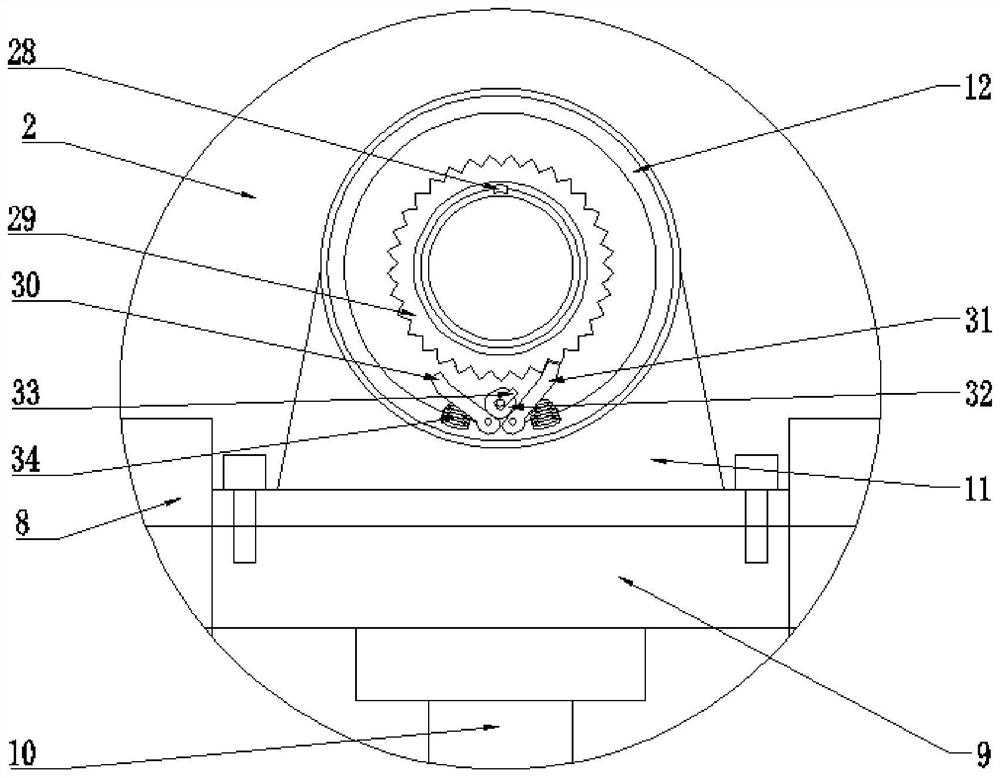

[0030] A group of vertical top braces are fixedly connected to the upper middle part of the two wishbones of the chassis, and each set of top braces includes a pair of support columns 7 fixedly connected to the same fork arm symmetrically. The slideway 8 is equipped with a lifting slider 9 in the lifting slideway, a jacking device 10 is arranged under the lifting slider, a ratchet seat 11 is detachably connected to the top of the lifting slider, and a two-way ratchet 12 is arranged in the ratchet seat. The inner coaxial fixed sleeve is provided with a rotating shaft 13, and the two ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com