Deep ploughing, smashing and soil loosening machine

A technology of soil loosening machine and variable speed machine, which is applied in the fields of tillage equipment, mechanical equipment, agricultural machinery and equipment, etc. It can solve the problems of shortening the service life of the loosening and powder ridge machine, the difficulty of resetting the rear floating device, and affecting the construction of operators. , to achieve the effect of not easy to get stuck, good shock absorption effect, and not easy to get stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

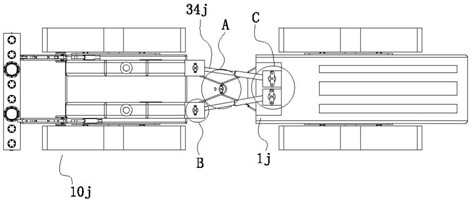

[0061] Such as Figure 1-Figure 24 As shown, a deep plowing crushing and loosening machine includes a front traction device 1j, a connecting mechanism 3j, a rear floating oil tank 2j, a traveling mechanism 10j and a deep plowing crushing and loosening device 4j. The front traction device 1j is connected to the rear floating oil tank 2j through the connecting mechanism 3j. The traveling mechanism is respectively hinged on both sides of the front traction device 1j and the rear floating fuel tank 2j, and the deep plowing, crushing and loosening device 4j is hinged on one side of the rear floating fuel tank 2j; the front traction device 1j is also provided with a cockpit 100j.

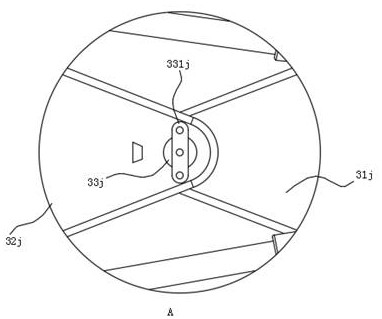

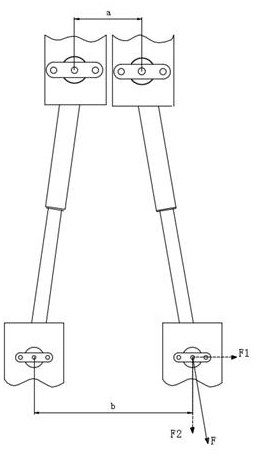

[0062] The connecting mechanism 3j includes a front connecting block 31j, a rear connecting block 32j, a joint bearing 33j and a hydraulic cylinder connecting mechanism. One end of the front connecting block 31j is fixedly connected to one side of the front traction device 1j, and the other end of the fron...

Embodiment 2

[0102] A kind of deep plowing crushing ripper, the difference from Embodiment 1 lies in the connection relationship between the heat dissipation oil tank, the heat dissipation connection assembly and the heat dissipation drive device, as shown in the figure Figure 25 and 26 as shown,

[0103] Deep plowing crushing loose soil device 4j comprises deep plowing crushing loose soil box 3b, the hydraulic motor 2h that is arranged on the top of deep plowing pulverizing loose soil box 3b, speed changer, driven rotating gear 34b, rotary cutter 5h, rotating shaft 33b, radiator oil tank 1b, heat dissipation Connect the assembly 2b and the heat dissipation drive device. The deep plowing, crushing and loosening box 3b is provided with a mounting seat 30b, and the mounting seat 30b is provided with a rotating shaft bearing. One end of the rotating shaft 33b passes through the rotating shaft bearing, the driven rotating gear 34b and The deep plowing crushing loose soil box 3b is hinged on ...

Embodiment 3

[0112] A kind of deep plowing crushing ripper; its difference from Embodiment 1 is only in the connection mode of the heat dissipation oil tank, the heat dissipation connection assembly and the heat dissipation drive device, such as Figure 27 As shown, the heat dissipation oil tank 1b, the heat dissipation connection assembly, the heat dissipation drive device and the cooling device 2b are installed on the deep plowing crushing loose soil box for use; the deep plowing crushing loose soil box is provided with a speed changer, a rotating shaft and a box cover; the rotating shaft More than one is provided; the speed changer includes a first speed changer 31b and a second speed changer 32b. In this embodiment, there is one heat dissipation driving device, and the heat dissipation driving device is the first heat dissipation driving device 41b. The height of the volume space of the cooling oil tank 1b is the same as that of the volume spaces of the first speed changer 31b and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com