Wood surface paint spraying device

A technology for wood surface and paint storage, applied in the field of wood processing, can solve the problems of high requirements for personnel operation and high cost, and achieve the effects of improving stability, improving mixing effect and avoiding deposition phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

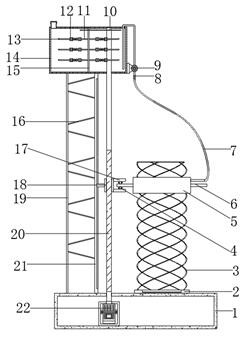

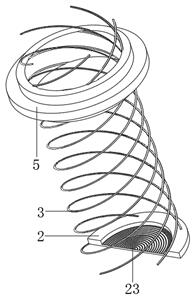

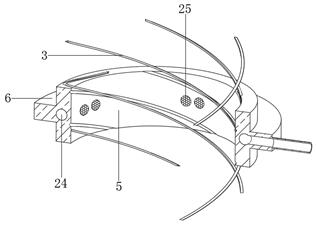

[0029] refer to Figure 1-4 , a wood surface painting device, comprising a chamber seat 1, the top outer wall side of the chamber seat 1 is fixed with a bottom 2 by bolts, the top outer wall of the bottom 2 is welded with a spiral rib tube 3, and one end of the spiral rib tube 3 is passed The ring cylinder 5 is threadedly connected, the inner wall side of the cavity seat 1 is fixed with a servo motor 22 by bolts, and the output shaft of the servo motor 22 is connected with a threaded column 20 through a coupling, and the top outer wall of the cavity seat 1 is vertically vertical on both sides at one end. The fixed support plate 21 and the side vertical bar 19 are directly welded, and the top of the fixed support plate 21 and the side vertical bar 19 is welded with the same paint storage bucket 14, and one end of the paint storage bucket 14 is connected with the driven rod 15 through bearing rotation, And the driven rod 15 is welded with equidistantly distributed fixed arm bars...

Embodiment 2

[0039] refer to Figure 5, a wood surface painting device, compared with Embodiment 1, this embodiment also includes a side of the movable scraper 13 fixedly equipped with a callback cylinder 26 distributed equidistantly; the callback cylinder 26 arranged on the movable scraper 13, It can be folded along with the movable scraper bar 13 to improve the callback effect of the paint.

[0040] In the present invention, the callback cylinder 26 is provided with cross-through grooves 27; during the callback process of the paint, the paint can be randomly extruded from the cross-through grooves 27, which is beneficial to further improve the chaos of the paint.

[0041] When the present invention is in use: through the dial-back cylinder 26 of the movable scraper 13 and the cross-through groove 27 on the dial-back cylinder 26, the movable scraper 13 can be folded to improve the dial-back effect on the paint, and the paint will During the callback process, it can be extruded at the cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com