Insulation board machining device and machining method

A processing device and insulation board technology, which is applied to the device and coating of the surface coating liquid, to achieve the effects of improving the pass rate and productivity, increasing the processing speed, and increasing the productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0052] Embodiment 1: In this embodiment, if Figure 5 As shown, the clamping member is a clamping plate 34 arranged on both sides of the fixing member, and the clamping plate 34 can move from both sides of the fixing member 31 to the center of the fixing member 31 in the horizontal direction, or Move in the opposite direction so that the two clamping plates 34 are close to each other or away from each other. When the two clamping plates 34 are close to each other, the clamping surfaces of the clamping plates 34 are against the two sides of the heat preservation board to form a clamp for the heat preservation board. hold. The surface-to-surface contact clamping method is adopted to make the contact area between the insulation board and the clamping parts larger, which increases the stability of the clamping and does not cause damage to the surface of the insulation board.

[0053] As preferably, the clamping surface of the splint 34 is provided with an anti-slip member to prev...

Embodiment approach 2

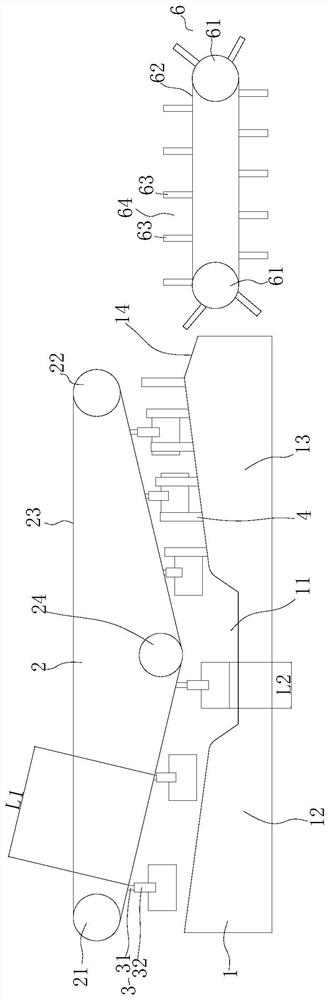

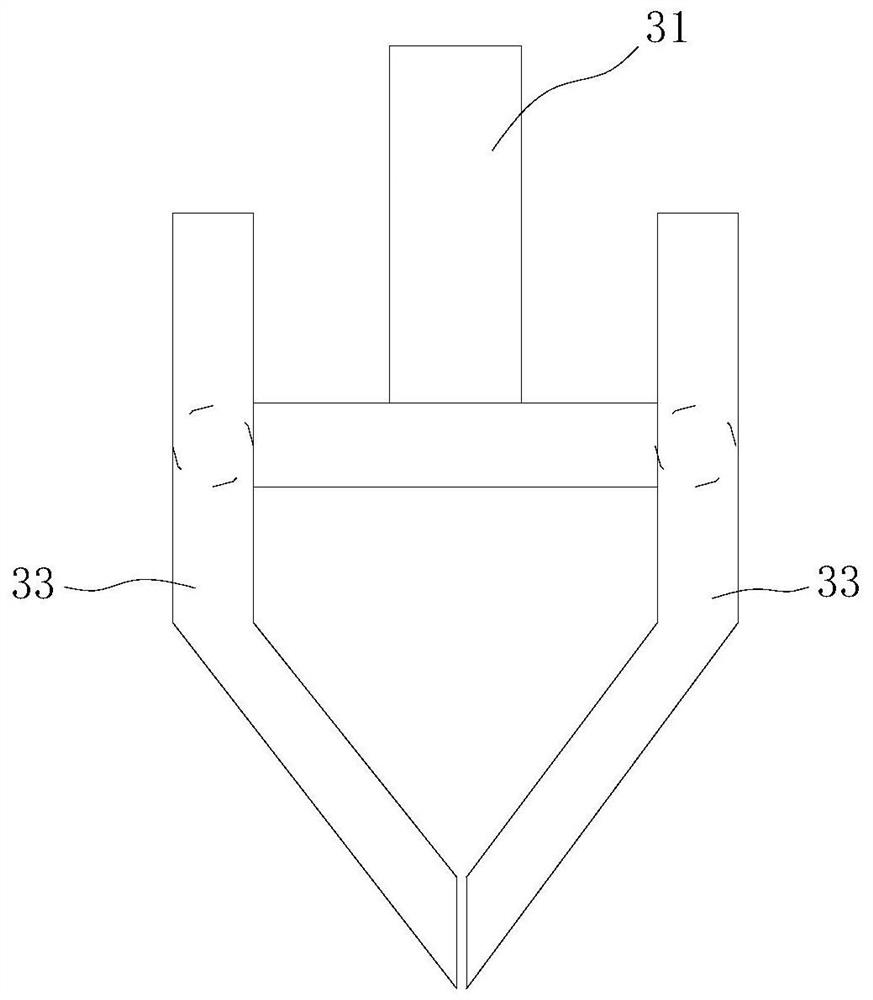

[0054] Embodiment 2: In this embodiment, if figure 1 , Figure 3-4 As shown, the clamping member 32 is a clamp 33 arranged on both sides of the fixing member 31 and rotatably connected with the fixing part 31. When the clamping member 32 is in the clamping state, the The clamp 33 rotates towards the direction of the clamp 33 on the other side of the fixing member 31; One side of the clamp 33 is turned in the direction.

[0055] The manner in which the clamping member 32 rotates relative to the fixing member 31 is easy to implement, and the principle of leverage can be used to lengthen the other end of the clamp 33 to realize that the control member can be rotated with a relatively small force. Controlling the opening and closing of the clamp 33 saves resources.

[0056] As a preference, an anti-slip member is provided on the side of the clamp 33 facing the insulation board to prevent the insulation board from slipping from the clamp 33 under its own gravity, and the anti-sl...

Embodiment 1

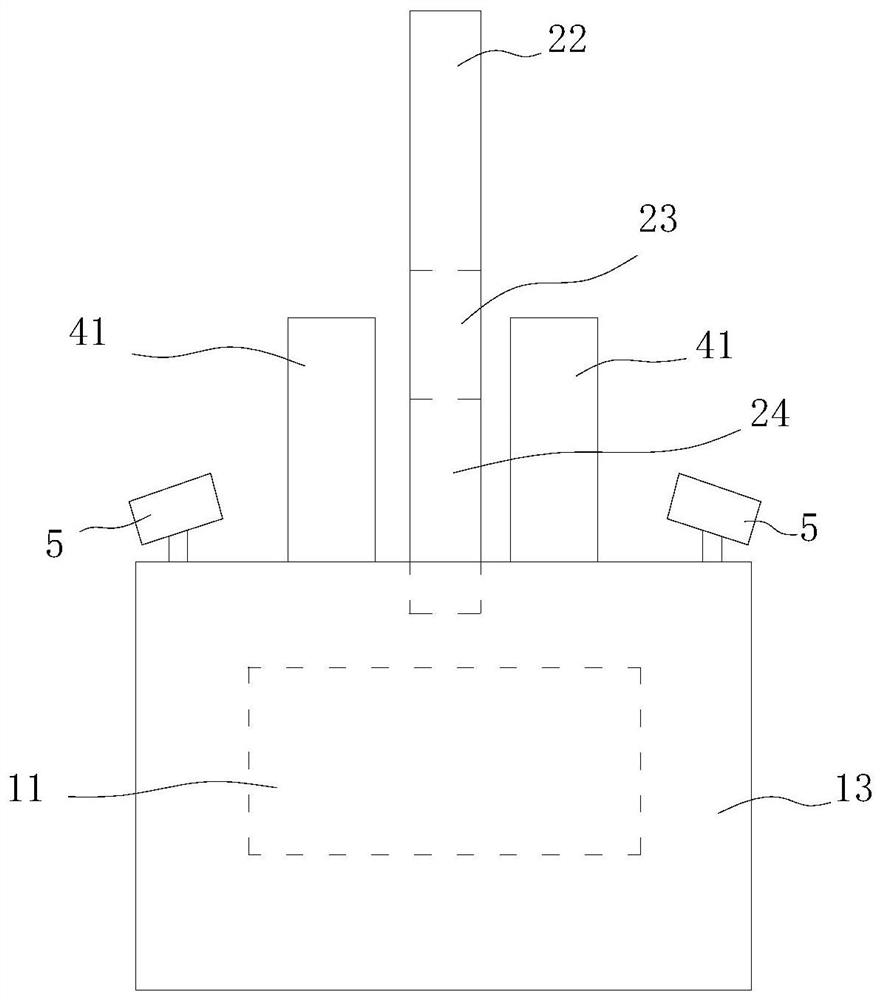

[0070] Embodiment 1: In this embodiment, the squeegee device 4 is a squeegee board arranged on both sides of the body 1 along the moving direction of the clamping device 3, and the squeegee board can quickly scrape the surface of the insulation board The excess slurry is scraped off, and the scraping effect is good.

[0071] As a preference, the squeegee is provided in multiple groups, and the distance between the squeegee of each group located on both sides of the body 1 is different, and the distance between the squeegee is along the clamping The moving direction of the device 3 decreases successively, and the distance between the group of scrapers farthest from the slurry tank 11 is the thickness of the standard insulation board after processing.

[0072] When the thermal insulation boards coated with paste pass through multiple sets of scrapers in sequence, the scraper scrapes off the excess slurry on the surface of the thermal insulation boards, so that the thickness of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com