Machining center water curtain system

A machining center and water curtain technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of debris residue, high cost, troublesome nozzle installation, etc., to achieve cost saving, simple installation, and improved effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

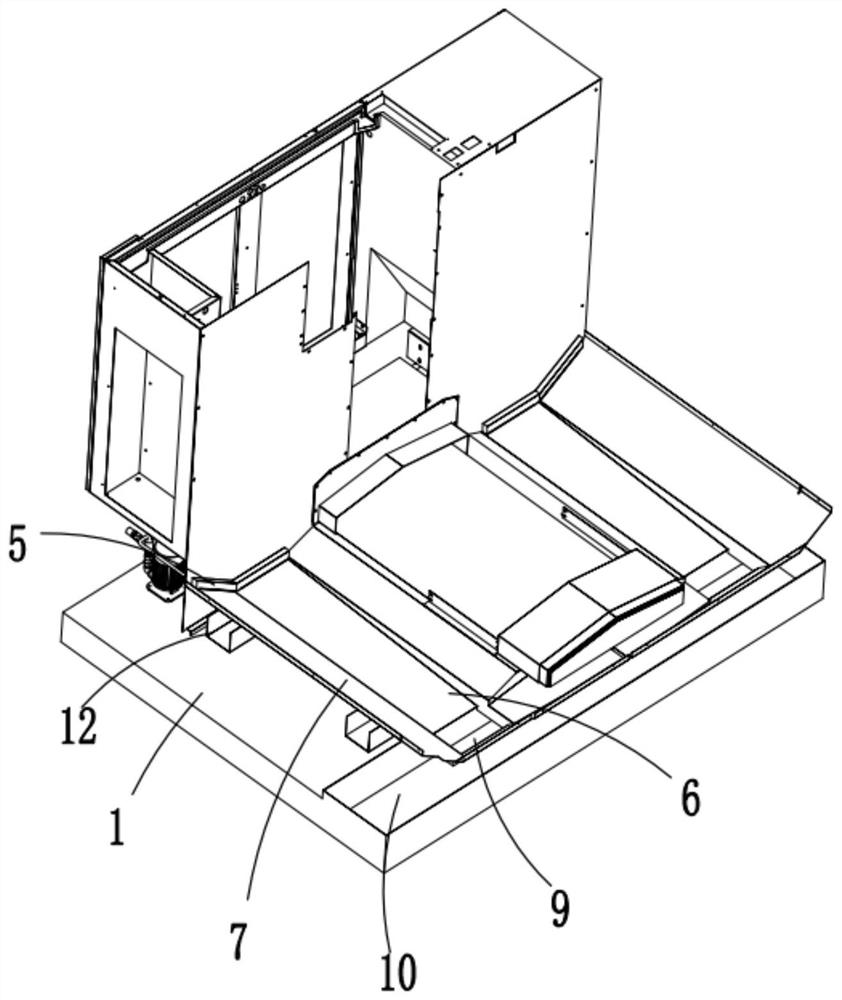

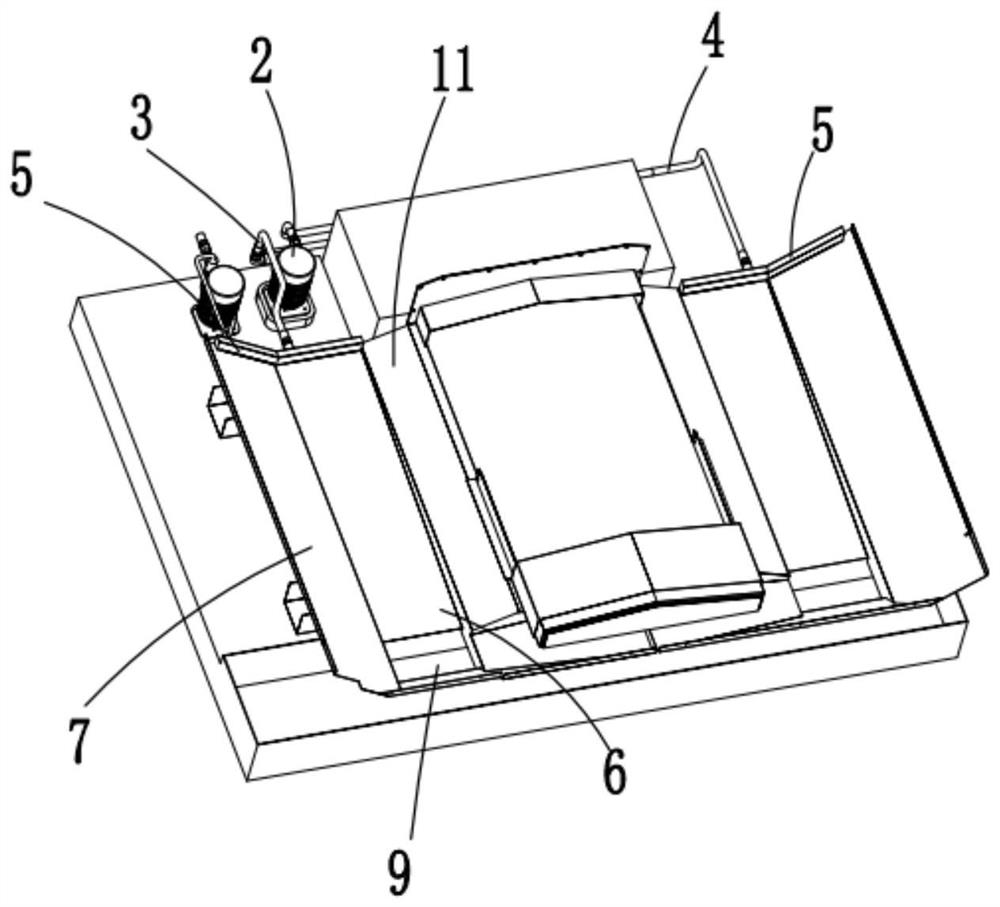

[0024] Such as figure 1 As shown, the water curtain system of the machining center of the present invention includes a water tank 1, a water pump 2 and a shower pipe 5. The water pump 2 is arranged on the top of the water tank 1 and draws water in the water tank 1 into the shower pipe 5. The water pump 2 The water outlets are respectively connected to the first water pipe 3 and the second water pipe 4. The first water pipe 3 and the second water pipe 4 respectively extend to the left and right sides of the top of the foundation and are connected to the shower pipe 5. The water pump 2 draws the shower liquid in the water tank 1 through The first water pipe 3 and the second water pipe 4 are respectively transported into the two shower pipes 5, and are flushed out through the shower pipes 5, and the flushed shower liquid forms a water curtain on the bottom plate to take away the debris attached to the bottom plate. crumbs.

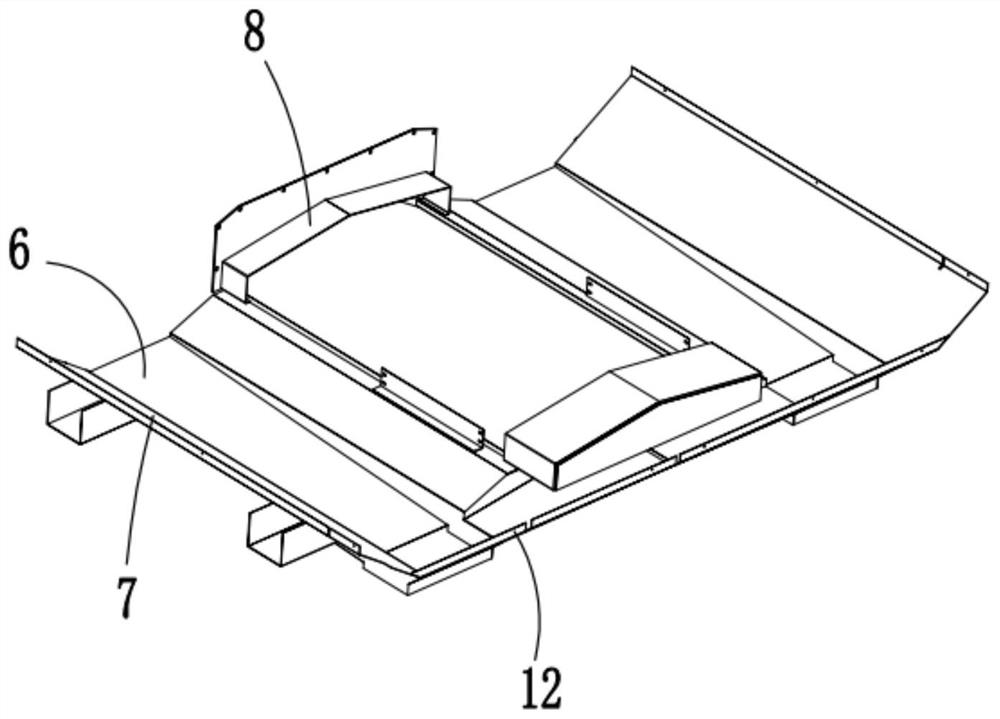

[0025] Such as figure 2 As shown, the base plate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com