Edge rounding device for wooden barrel production

A technology for rounding corners and edges, which is applied in the field of edge rounding devices for wooden barrel production. It can solve the problems of labor time-consuming and labor-consuming, and debris falling everywhere, so as to improve work efficiency, polish evenly, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

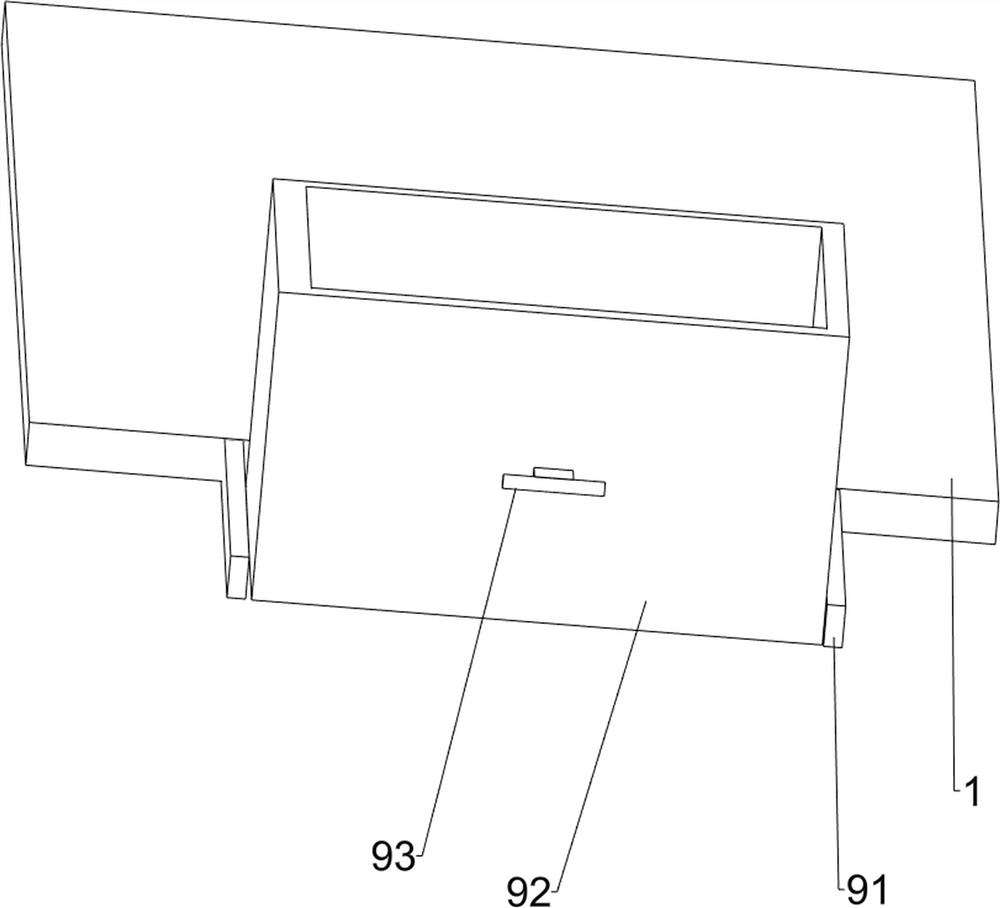

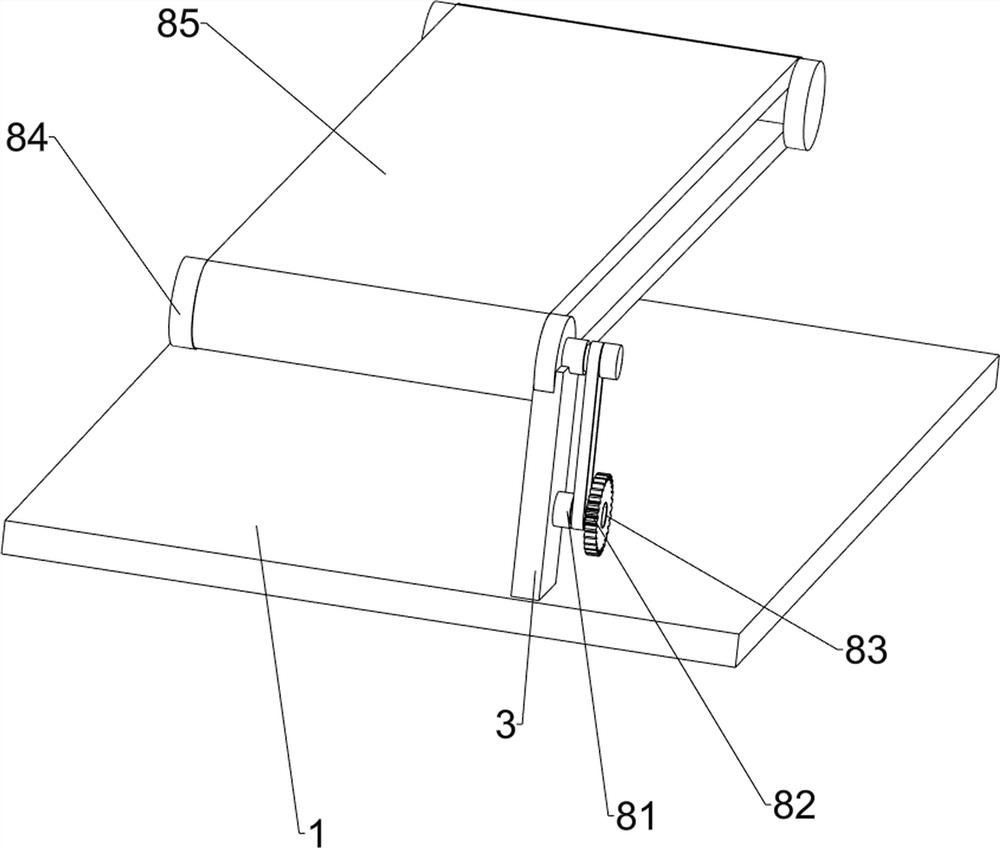

[0028] An edge rounding device for barrel production, such as Figure 1-Figure 3 As shown, it includes a base 1, a support seat 2, a bracket 3, a fixing mechanism 4 and a grinding mechanism 5. The left side of the base 1 is provided with a support seat 2, the base 1 is surrounded by a bracket 3, and the top of the bracket 3 is provided with a fixing mechanism. 4. The top of the fixing mechanism 4 is provided with a grinding mechanism 5 .

[0029] When people need to polish the barrel, the barrel is first placed on the fixing mechanism 4, the barrel is fixed, the grinding mechanism 5 is started, and the edge of the barrel is polished by the polishing mechanism 5. After polishing, the wooden barrel is fixed by the fixing mechanism 4. The barrel is taken out and put into a new wooden barrel for polishing, and the cycle repeats so that the wooden barrel can be continuously polished.

[0030] The fixing mechanism 4 includes a first sliding column 41, a first fixing column 42, an a...

Embodiment 2

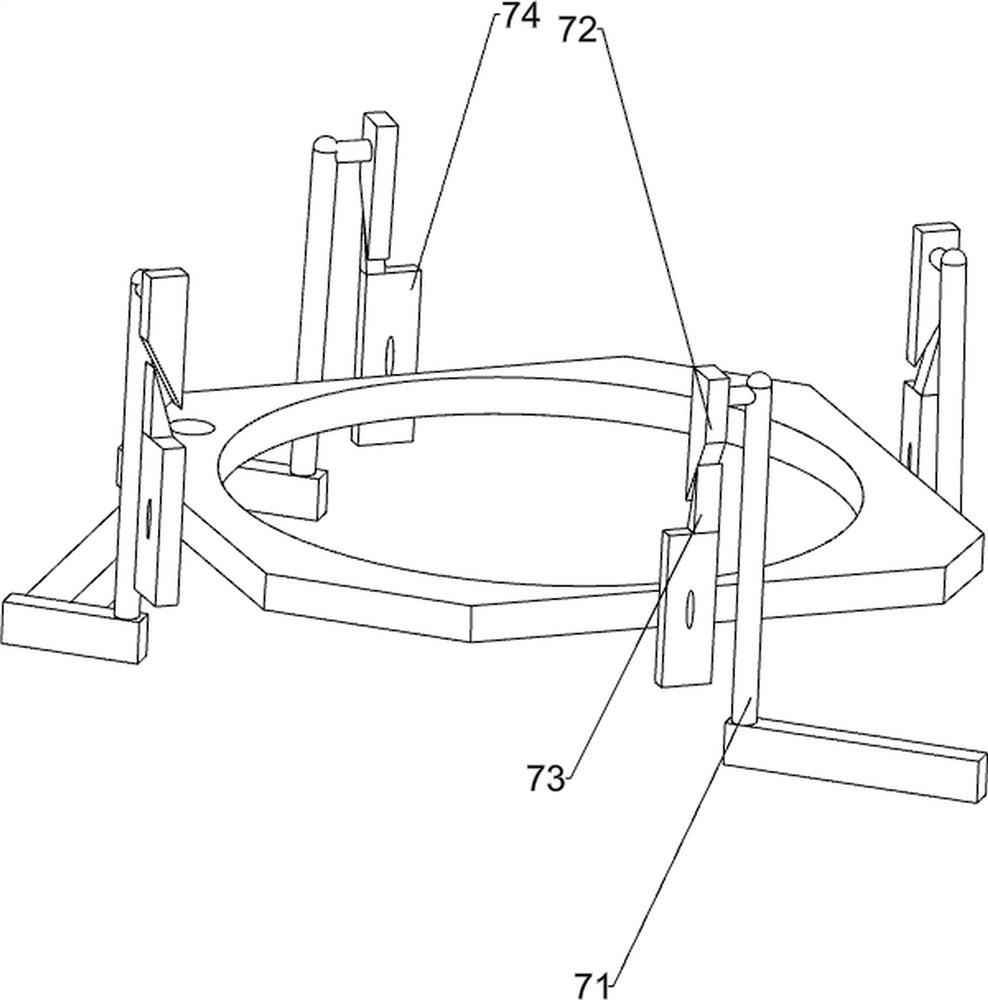

[0035] On the basis of Example 1, such as figure 1 , Figure 4-Figure 7 As shown, a reciprocating mechanism 6 is also included. The front portion of the base 1 is provided with a reciprocating mechanism 6. The reciprocating mechanism 6 includes a second motor 61, a second rotating shaft 62, a fifth fixed post 63, a half gear 64, a second A gear 65, the sixth fixed column 66, the first transmission assembly 67, the fourth rotating column 68 and the seventh rotating column 69, the support base 2 is provided with a second motor 61, and the output shaft of the second motor 61 is connected with a The second rotating shaft 62, the left front end of the base 1 is provided with two fifth fixed posts 63, the second rotating shaft 62 is rotationally connected with the fifth fixed post 63 on the left side, and the front end of the second rotating shaft 62 is provided with half Gear 64, the fifth fixed column 63 on the right side is rotatably provided with first gear 65, the upper middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com